© 2007 Alamo Group Inc.

Maintenance Section 5-5

SL60 03/07

MAINTENANCE

BLADE REMOVAL

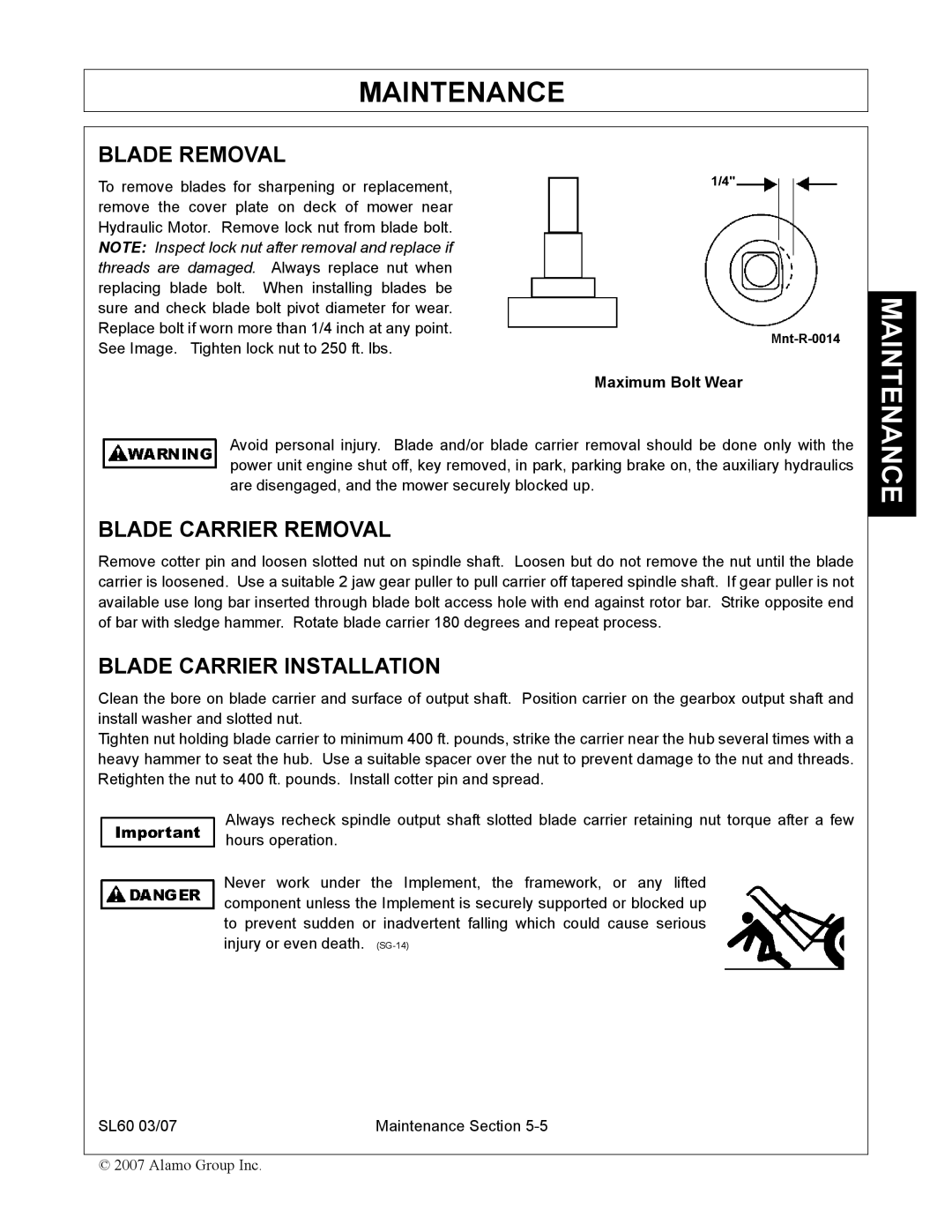

To remove blades for sharpening or replacement, remove the cover plate on deck of mower near Hydraulic Motor. Remove lock nut from blade bolt. NOTE: Inspect lock nut after removal and replace if threads are damaged. Always replace nut when replacing blade bolt. When installing blades be sure and check blade bolt pivot diameter for wear. Replace bolt if worn more than 1/4 inch at any point. See Image. Tighten lock nut to 250 ft. lbs.

Maximum Bolt Wear

Avoid personal injury. Blade and/or blade carrier removal should be done only with the power unit engine shut off, key removed, in park, parking brake on, the auxiliary hydraulics are disengaged, and the mower securely blocked up.

BLADE CARRIER REMOVAL

Remove cotter pin and loosen slotted nut on spindle shaft. Loosen but do not remove the nut until the blade carrier is loosened. Use a suitable 2 jaw gear puller to pull carrier off tapered spindle shaft. If gear puller is not available use long bar inserted through blade bolt access hole with end against rotor bar. Strike opposite end of bar with sledge hammer. Rotate blade carrier 180 degrees and repeat process.

BLADE CARRIER INSTALLATION

Clean the bore on blade carrier and surface of output shaft. Position carrier on the gearbox output shaft and install washer and slotted nut.

Tighten nut holding blade carrier to minimum 400 ft. pounds, strike the carrier near the hub several times with a heavy hammer to seat the hub. Use a suitable spacer over the nut to prevent damage to the nut and threads. Retighten the nut to 400 ft. pounds. Install cotter pin and spread.

Always recheck spindle output shaft slotted blade carrier retaining nut torque after a few hours operation.

Never work under the Implement, the framework, or any lifted component unless the Implement is securely supported or blocked up to prevent sudden or inadvertent falling which could cause serious injury or even death. (SG-14)