Electric Fryer, ASF-60E, ASF-75E specifications

The Alto-Shaam ASF-75E and ASF-60E electric fryers represent a significant advancement in commercial kitchen equipment, designed to meet the high demands of professional food preparation. Both models are engineered with an emphasis on efficiency, precision, and safety, ensuring that operators can achieve consistent, high-quality results.The Alto-Shaam ASF-75E boasts a capacity of 75 pounds, making it ideal for high-volume frying applications. Its companion model, the ASF-60E, is slightly smaller, with a capacity of 60 pounds. This makes both fryers versatile options for restaurants, catering services, and other food service operations that require reliable frying capabilities without compromising on quality.

One of the standout features of both models is their advanced heating technology, which utilizes durable, heat-conducting elements that deliver consistent temperatures. This ensures that food is fried evenly and reduces the risk of undercooked or overcooked items. The fryers also come equipped with a precise digital temperature control, allowing operators to set specific frying temperatures and times, further enhancing cooking consistency.

Another key element is the innovative oil filtration system integrated into both fryers. This technology helps extend the life of the cooking oil, reducing costs and increasing operational efficiency. By filtering oil during cooking, the fryers maintain optimal frying conditions and improve the flavor profile of fried foods, making them more appealing to customers.

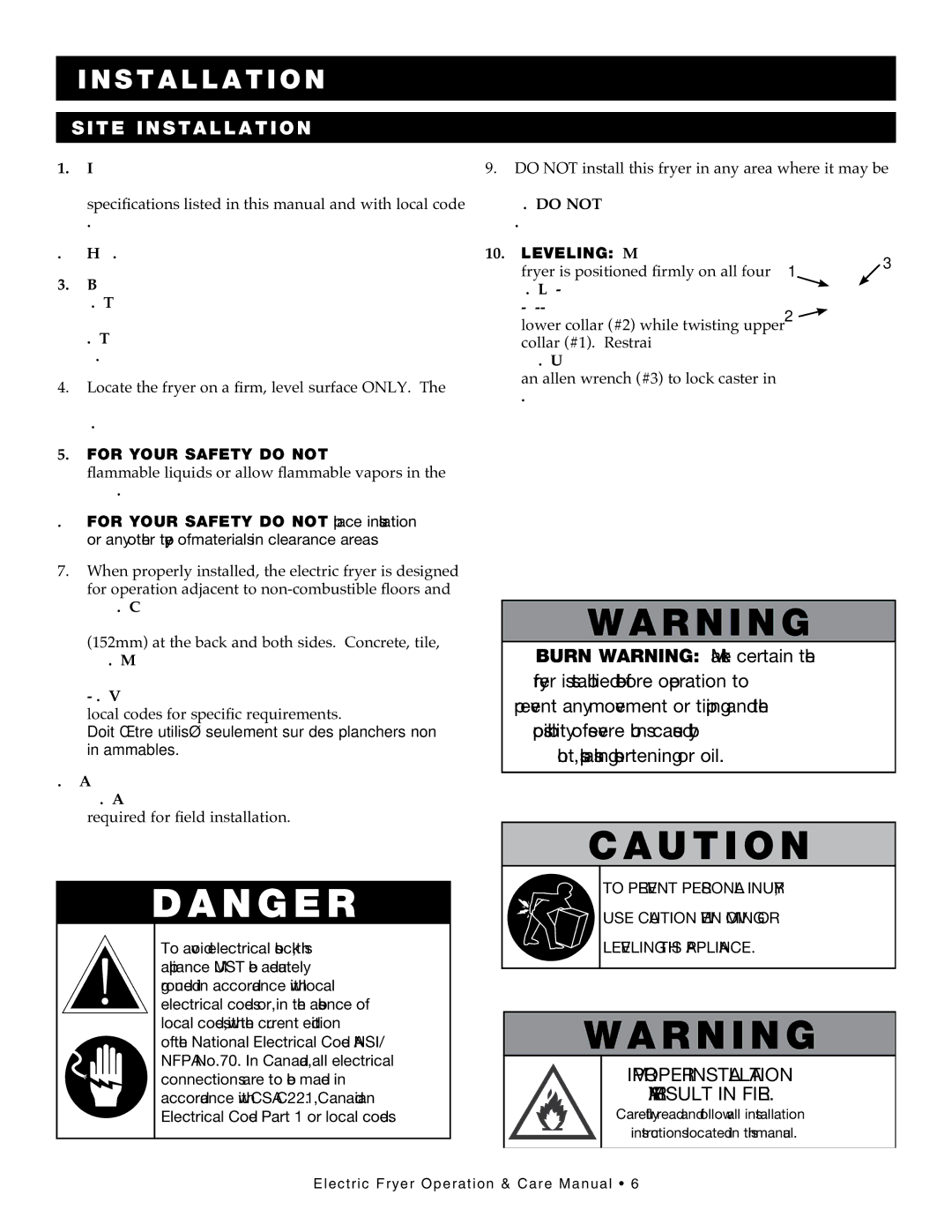

Safety is paramount in commercial kitchens, and Alto-Shaam prioritizes this with features such as a cool-to-the-touch exterior, ensuring operators can work safely without the risk of burns. Additionally, the fryers have built-in safety shut-off systems, which automatically turn off the heating elements if oil temperatures exceed safe levels.

Designed for ease of use, both models have simple control panels that are intuitive for operators of all skill levels. Their compact, space-saving designs make them easy to integrate into any kitchen layout without requiring excessive floor space.

In summary, the Alto-Shaam ASF-75E and ASF-60E electric fryers are engineered with state-of-the-art technologies that cater to the specific needs of commercial kitchens. With their efficient heating systems, advanced oil filtration, and strong safety features, these fryers not only enhance productivity but also contribute to delivering exceptional fried foods that keep patrons coming back for more.