Ice Maker

Ejector Blades or Stripper

1.Remove module and support assembly.

2.Install ejector blades, realigning "D" coupling with module cam.

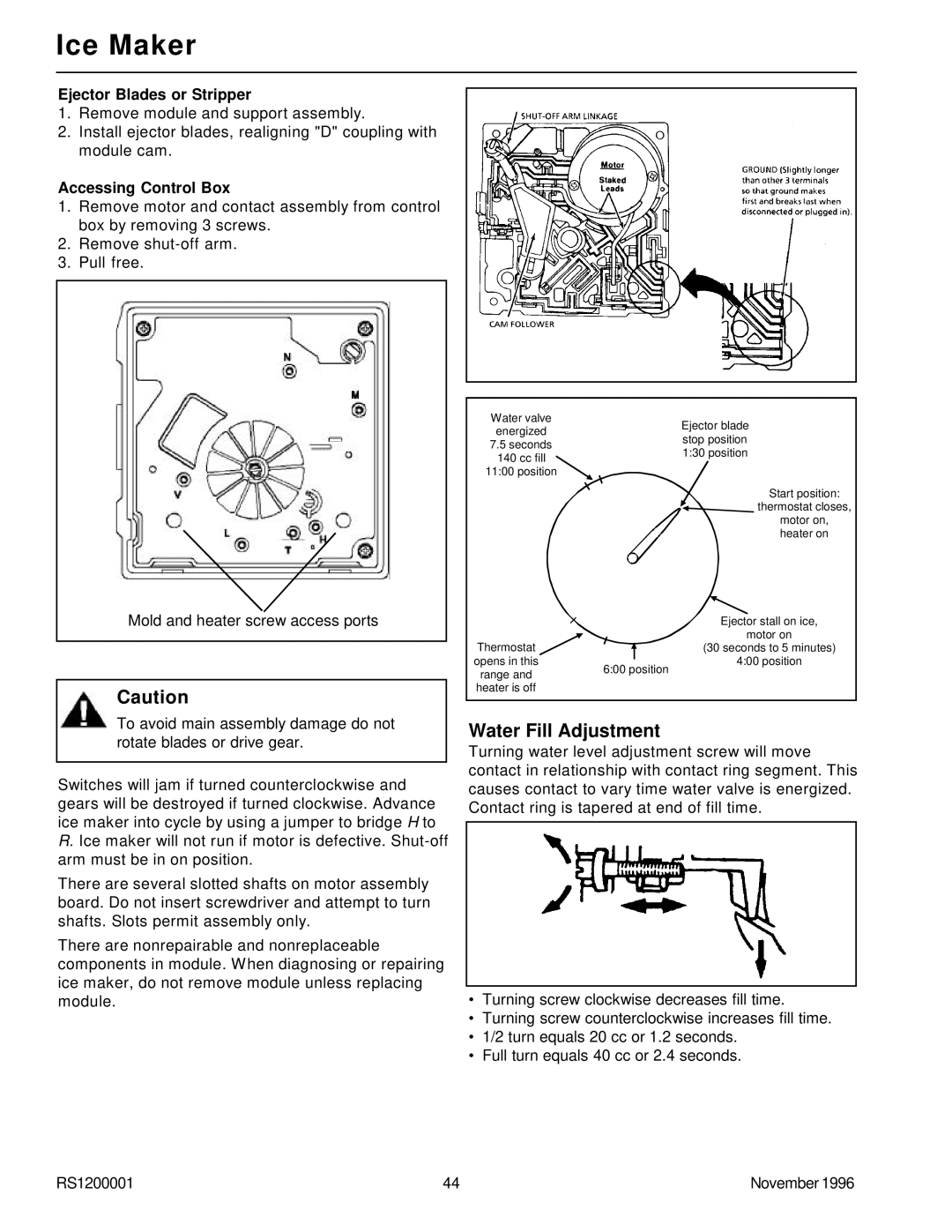

Accessing Control Box

1.Remove motor and contact assembly from control box by removing 3 screws.

2.Remove

3.Pull free.

Mold and heater screw access ports

Caution

To avoid main assembly damage do not rotate blades or drive gear.

Switches will jam if turned counterclockwise and gears will be destroyed if turned clockwise. Advance ice maker into cycle by using a jumper to bridge H to R. Ice maker will not run if motor is defective.

There are several slotted shafts on motor assembly board. Do not insert screwdriver and attempt to turn shafts. Slots permit assembly only.

There are nonrepairable and nonreplaceable components in module. When diagnosing or repairing ice maker, do not remove module unless replacing module.

Water valve | Ejector blade | |

energized | ||

stop position | ||

7.5 seconds | ||

1:30 position | ||

140 cc fill | ||

| ||

11:00 position |

|

Start position:

![]() thermostat closes,

thermostat closes,

motor on, heater on

| Ejector stall on ice, |

Thermostat | motor on |

(30 seconds to 5 minutes) | |

opens in this | 4:00 position |

range and | 6:00 position |

heater is off |

|

Water Fill Adjustment

Turning water level adjustment screw will move contact in relationship with contact ring segment. This causes contact to vary time water valve is energized. Contact ring is tapered at end of fill time.

•Turning screw clockwise decreases fill time.

•Turning screw counterclockwise increases fill time.

•1/2 turn equals 20 cc or 1.2 seconds.

•Full turn equals 40 cc or 2.4 seconds.

RS1200001 | 44 | November 1996 |