Ice Maker

Caution

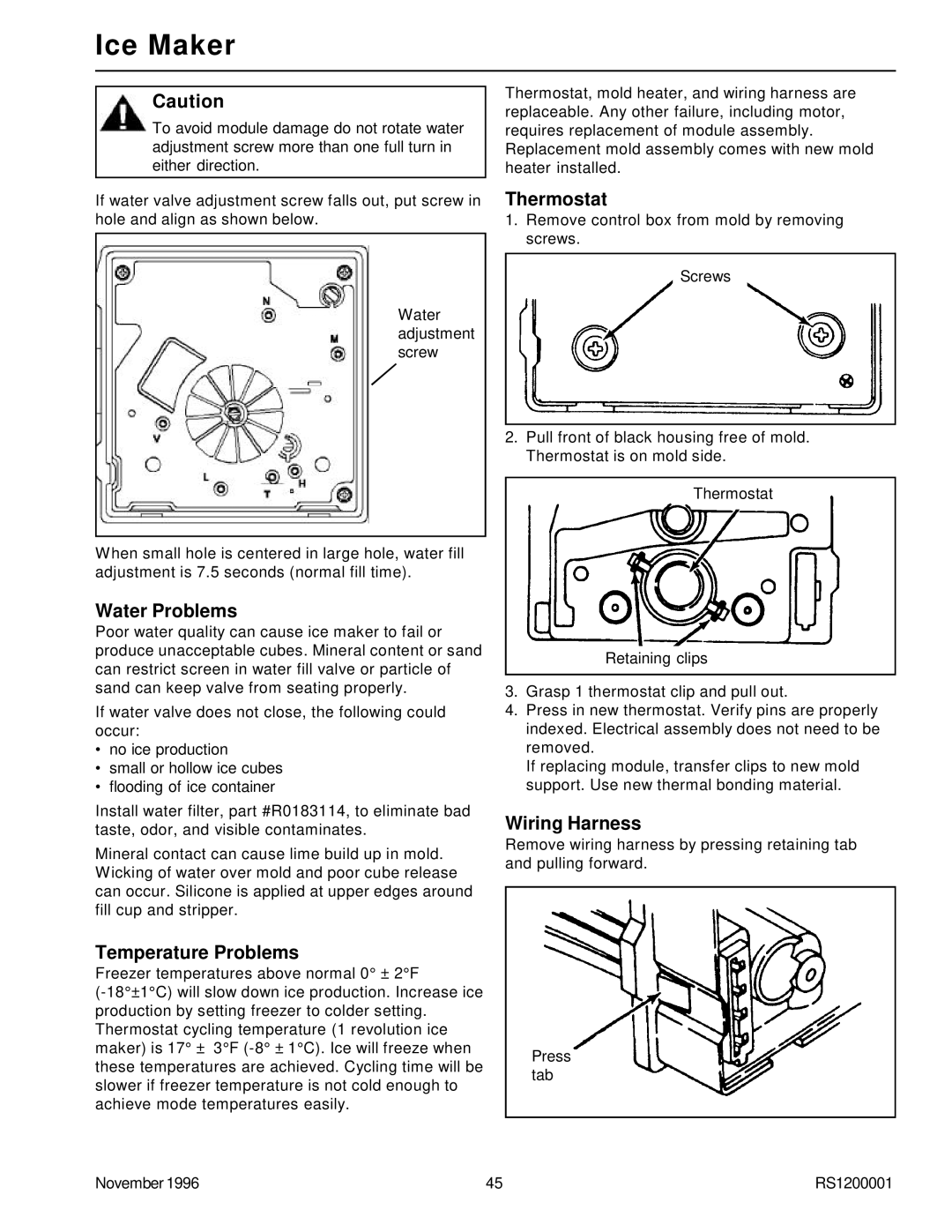

To avoid module damage do not rotate water adjustment screw more than one full turn in either direction.

If water valve adjustment screw falls out, put screw in hole and align as shown below.

Water adjustment screw

When small hole is centered in large hole, water fill adjustment is 7.5 seconds (normal fill time).

Thermostat, mold heater, and wiring harness are replaceable. Any other failure, including motor, requires replacement of module assembly. Replacement mold assembly comes with new mold heater installed.

Thermostat

1.Remove control box from mold by removing screws.

Screws

2.Pull front of black housing free of mold. Thermostat is on mold side.

Thermostat

Water Problems

Poor water quality can cause ice maker to fail or produce unacceptable cubes. Mineral content or sand can restrict screen in water fill valve or particle of sand can keep valve from seating properly.

If water valve does not close, the following could occur:

•no ice production

•small or hollow ice cubes

•flooding of ice container

Install water filter, part #R0183114, to eliminate bad taste, odor, and visible contaminates.

Mineral contact can cause lime build up in mold. Wicking of water over mold and poor cube release can occur. Silicone is applied at upper edges around fill cup and stripper.

Retaining clips

3.Grasp 1 thermostat clip and pull out.

4.Press in new thermostat. Verify pins are properly indexed. Electrical assembly does not need to be removed.

If replacing module, transfer clips to new mold support. Use new thermal bonding material.

Wiring Harness

Remove wiring harness by pressing retaining tab and pulling forward.

Temperature Problems

Freezer temperatures above normal 0° ± 2°F

Press tab

November 1996 | 45 | RS1200001 |