AGM300, ADM800 specifications

The Bacharach ADM 800 and AGM 300 are advanced analyzers designed for efficient monitoring and detection of gases in various applications. Known for their reliability and accuracy, these instruments cater to commercial and industrial sectors, ensuring safety and compliance with environmental regulations.The Bacharach ADM 800 is a portable gas detection device renowned for its ability to detect multiple refrigerants. With a user-friendly interface, it features a high-resolution display that provides real-time data on refrigerant concentrations, allowing technicians to quickly identify leaks during maintenance operations. One of its standout technologies is a highly sensitive thermal conductivity sensor, which enables the ADM 800 to differentiate between various hydrocarbon refrigerants with precision.

Equipped with data logging capabilities, the ADM 800 can store and retrieve measurement data, making it an invaluable tool for tracking refrigerant trends over time. The device supports USB connectivity for easy transfer of data to computers, facilitating detailed reporting and analysis. Its robust design incorporates a protective casing that ensures durability in challenging work environments, making it ideal for both field use and stationary applications.

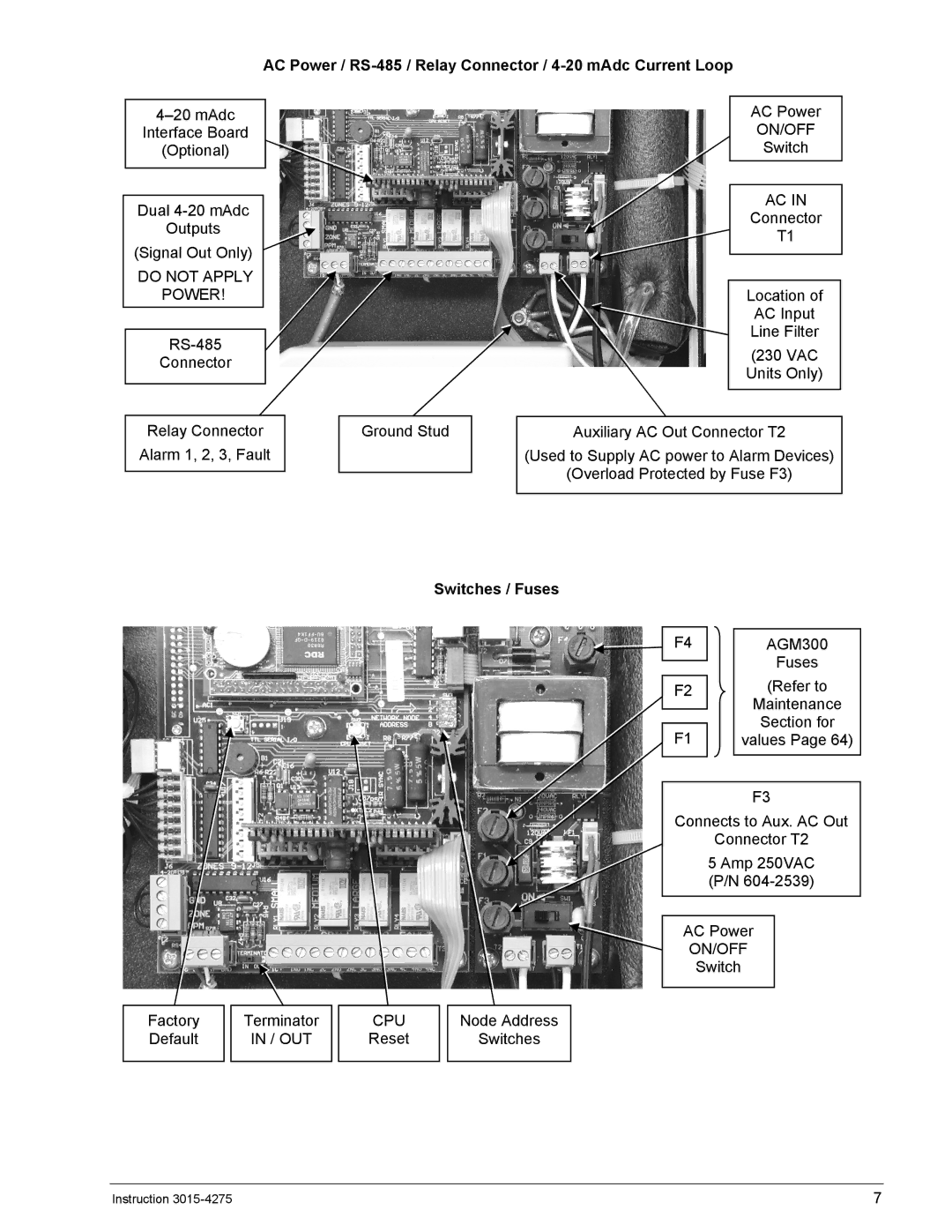

On the other hand, the Bacharach AGM 300 is specifically crafted for continuous gas monitoring in HVAC systems. This stationary device excels in measuring concentrations of gases such as CO, CO2, and various refrigerants, ensuring optimal performance and compliance. The AGM 300 uses advanced electrochemical sensors for precise gas measurements, providing real-time feedback and alerting users to any hazardous conditions.

One of the notable features of the AGM 300 is its ability to integrate seamlessly with building management systems, enabling centralized control and monitoring of gas levels across multiple locations. This connectivity enhances the safety of industrial and commercial spaces by allowing for automated responses to detected gas levels, which can significantly mitigate risks associated with gas leaks.

Both models emphasize user-centric design, with intuitive interfaces and clear displays, making them accessible even to those with minimal training. Additionally, their low maintenance requirements and long sensor life contribute to reduced operational costs.

In conclusion, the Bacharach ADM 800 and AGM 300 are exemplary solutions for gas detection and monitoring. Their advanced technologies, robust features, and user-friendly designs make them indispensable for ensuring safety and regulatory compliance in various environments.