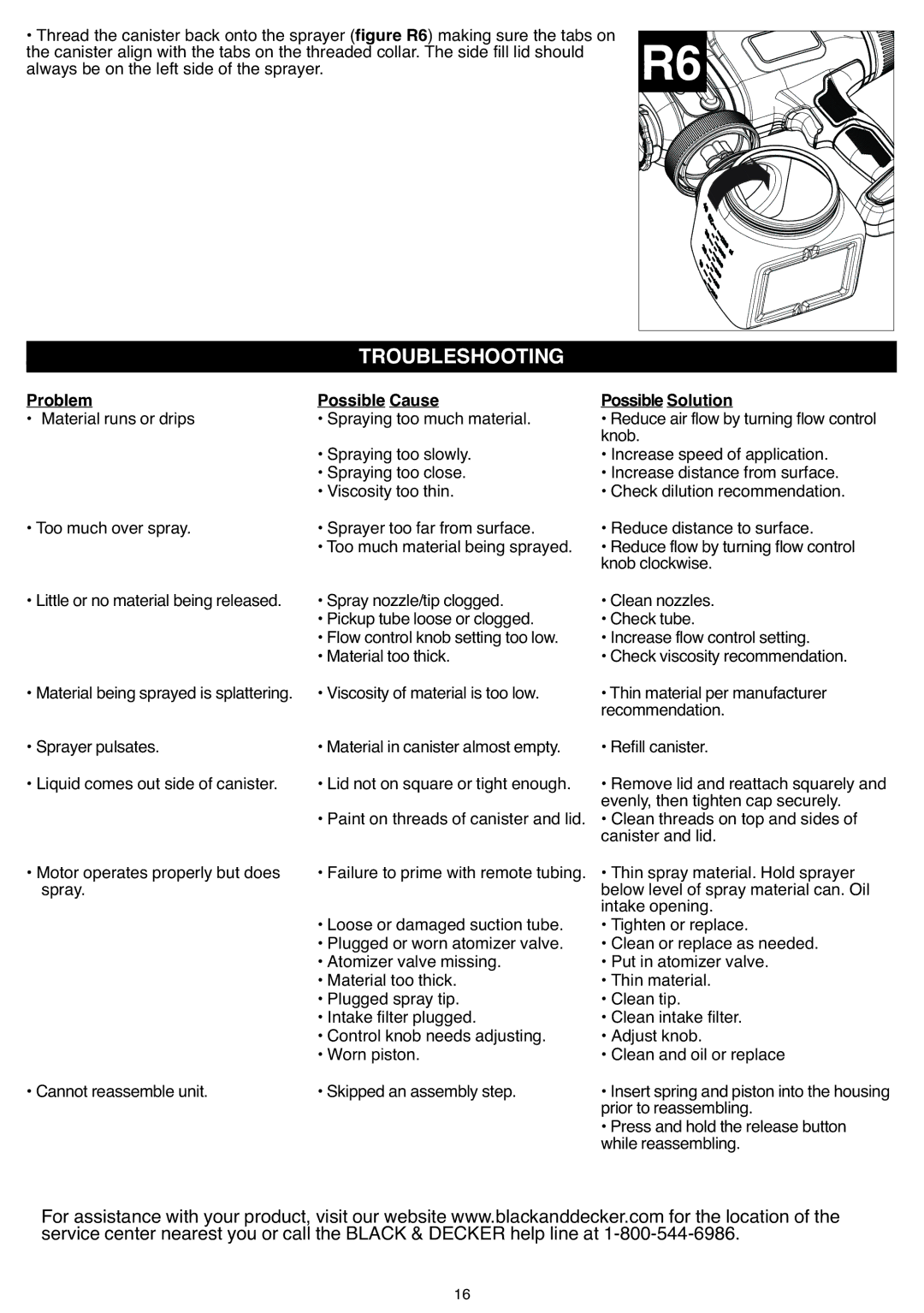

• Thread the canister back onto the sprayer (figure R6) making sure the tabs on | R6 |

the canister align with the tabs on the threaded collar. The side fill lid should |

|

always be on the left side of the sprayer. |

|

TROUBLESHOOTING |

|

Problem | Possible Cause | Possible Solution |

• Material runs or drips | • Spraying too much material. | • Reduceair flow by turning flow control |

| • Spraying too slowly. | knob. |

| • Increase speed of application. | |

| • Spraying too close. | • Increase distance from surface. |

• Too much over spray. | • Viscosity too thin. | • Check dilution recommendation. |

• Sprayer too far from surface. | • Reduce distance to surface. | |

| • Too much material being sprayed. | • Reduce flow by turningflow control |

• Little or no materialbeing released. | • Spray nozzle/tip clogged. | knob clockwise. |

• Cleannozzles. | ||

| • Pickup tube loose or clogged. | • Check tube. |

| • Flow control knob setting too low. | • Increase flow controlsetting. |

• Materialbeingsprayedis splattering. | • Material too thick. | • Check viscosity recommendation. |

• Viscosity of material is too low. | • Thin material per manufacturer | |

• Sprayer pulsates. | • Material in canister almostempty. | recommendation. |

• Refill canister. | ||

• Liquid comes out side of canister. | • Lid not on square or tight enough. | • Remove lid and reattach squarely and |

| • Paint on threads of canister and lid. | evenly, then tighten cap securely. |

| • Clean threads on top and sides of | |

• Motor operates properly but does | • Failure to prime with remote tubing. | canister and lid. |

• Thin spray material. Hold sprayer | ||

spray. |

| below level of spray material can. Oil |

| • Loose or damaged suction tube. | intake opening. |

| • Tighten or replace. | |

| • Plugged or worn atomizer valve. | • Clean or replace as needed. |

| • Atomizer valve missing. | • Put in atomizer valve. |

| • Material too thick. | • Thin material. |

| • Plugged spray tip. | • Clean tip. |

| • Intake filter plugged. | • Clean intake filter. |

| • Control knob needs adjusting. | • Adjust knob. |

• Cannot reassembleunit. | • Worn piston. | • Clean and oil or replace |

• Skipped an assembly step. | • Insertspringand pistoninto the housing | |

|

| prior to reassembling. |

|

| • Press and hold the release button |

|

| while reassembling. |

For assistance with your product, visit our website www.blackanddecker.com for the location of the service center nearest you or call the BLACK & DECKER help line at

16