LIQUID MATERIAL PREPARATION - (FIGURES , E1) |

|

TIP: Make sure the type of material you |

|

use can be cleaned with either mineral |

|

spirits or paint thinner (for |

|

paints) or a warm water and soap solution |

|

(for water soluble paints like latex). Use |

|

drop cloths during pouring, mixing, and |

|

viscosity testing of materials to be |

|

sprayed to protect your floors and |

|

anything else in the spraying area that |

|

you wish to remain untouched. |

|

The liquid being sprayed may need to be |

|

thinned (diluted) before starting. When thin- |

|

ning, use the proper liquid thinner recom- |

|

mended on the container by the material |

|

manufacturer and the proper dilution rate. |

|

WARNING: Do not use materials with |

|

a flashpoint higher than 60°C (140°F) . |

|

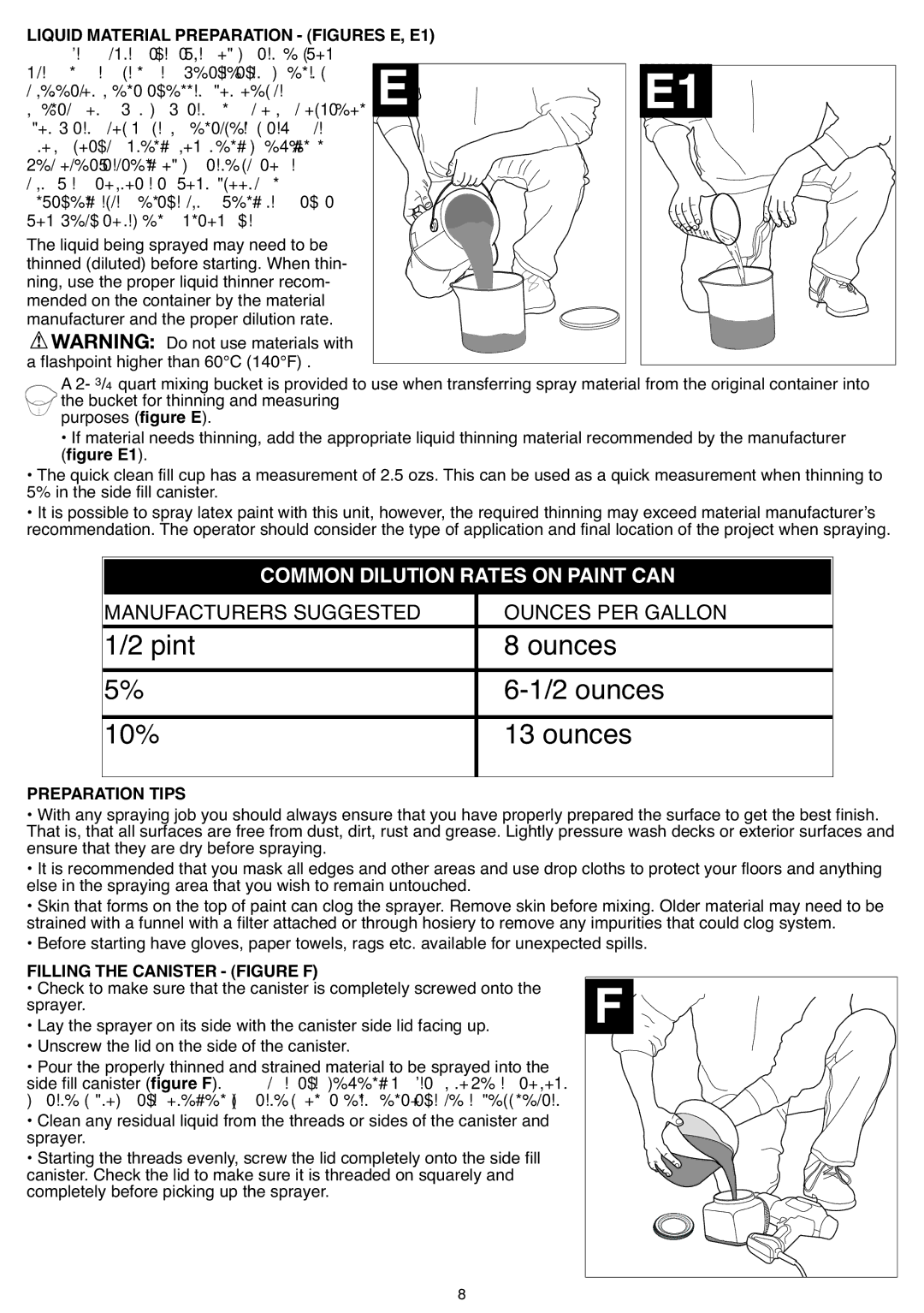

A 2- 3/4 quart mixing bucket is provided to use when transferring spray material from the original container into | |

the bucket for thinning and measuring |

|

purposes (figure E). |

|

• If material needs thinning, add the appropriate liquid thinning material recommended by the manufacturer | |

(figure E1). |

|

• The quick clean fill cup has a measurement of 2.5 ozs. This can be used as a quick measurement when thinning to | |

5% in the side fill canister. |

|

• It is possible to spray latex paint with this unit, however, the required thinning may exceed material manufacturerʼs | |

recommendation. The operator should consider the type of application and final location of the project when spraying. | |

COMMON DILUTION RATES ON PAINT CAN | |

MANUFACTURERS SUGGESTED | OUNCES PER GALLON |

1/2 pint | 8 ounces |

5% |

|

10% | 13 ounces |

PREPARATION TIPS |

|

• With any spraying job you should always ensure that you have properly prepared the surface to get the best finish. | |

That is, that all surfaces are free from dust, dirt, rust and grease. Lightly pressure wash decks or exterior surfaces and | |

ensure that they are dry before spraying. |

|

• It is recommended that you mask all edges and other areas and use drop cloths to protect your floors and anything | |

else in the spraying area that you wish to remain untouched. |

|

• Skin that forms on the top of paint can clog the sprayer. Remove skin before mixing. Older material may need to be | |

strained with a funnel with a filter attached or through hosiery to remove any impurities that could clog system. | |

• Before starting have gloves, paper towels, rags etc. available for unexpected spills. | |

FILLING THE CANISTER - (FIGURE F) |

|

• Check to make sure that the canister is completely screwed onto the | |

sprayer. |

|

• Lay the sprayer on its side with the canister side lid facing up. |

|

• Unscrew the lid on the side of the canister. |

|

• Pour the properly thinned and strained material to be sprayed into the | |

side fill canister (figure F). TIP: Use the mixing bucket provided to pour | |

material from the original material container into the side fill canister. | |

• Clean any residual liquid from the threads or sides of the canister and | |

sprayer. |

|

• Starting the threads evenly, screw the lid completely onto the side fill | |

canister. Check the lid to make sure it is threaded on squarely and | |

completely before picking up the sprayer. |

|

8