Caution: Do Not Exceed 30 VAC Input on

24 VAC models. Operation above 30 VAC violates low voltage operation (Class 2 Specifications). Normal operation is 24 VAC. CUL Approved 24 VAC Models.

Caution: Connect to Class 2 Power Supply only. Total current through electrical connector is 4 A maximum. Pan/tilt current is 1 A maximum. Allowable camera/housing is 3 A maximum. Use only 24 VAC cameras and housings on

3.2Recommended Mounting Equipment

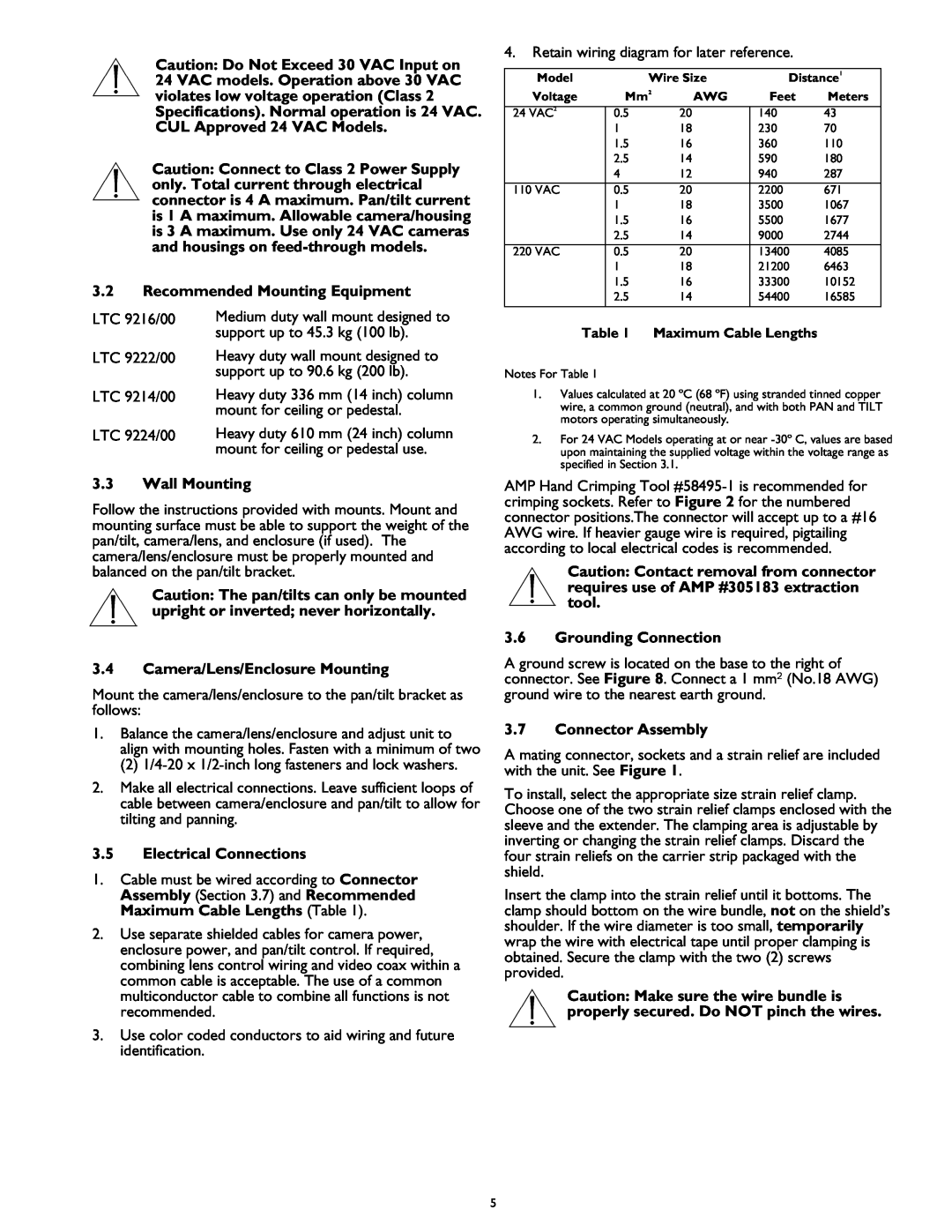

4.Retain wiring diagram for later reference.

Model | Wire Size | Distance1 | ||

Voltage | Mm2 | AWG | Feet | Meters |

|

|

|

|

|

24 VAC2 | 0.5 | 20 | 140 | 43 |

| 1 | 18 | 230 | 70 |

| 1.5 | 16 | 360 | 110 |

| 2.5 | 14 | 590 | 180 |

| 4 | 12 | 940 | 287 |

|

|

|

|

|

110 VAC | 0.5 | 20 | 2200 | 671 |

| 1 | 18 | 3500 | 1067 |

| 1.5 | 16 | 5500 | 1677 |

| 2.5 | 14 | 9000 | 2744 |

220 VAC | 0.5 | 20 | 13400 | 4085 |

| 1 | 18 | 21200 | 6463 |

| 1.5 | 16 | 33300 | 10152 |

| 2.5 | 14 | 54400 | 16585 |

|

|

|

|

|

LTC 9216/00

LTC 9222/00

LTC 9214/00

LTC 9224/00

Medium duty wall mount designed to support up to 45.3 kg (100 lb).

Heavy duty wall mount designed to support up to 90.6 kg (200 lb).

Heavy duty 336 mm (14 inch) column mount for ceiling or pedestal.

Heavy duty 610 mm (24 inch) column mount for ceiling or pedestal use.

Table 1 Maximum Cable Lengths

Notes For Table 1

1.Values calculated at 20 ºC (68 ºF) using stranded tinned copper wire, a common ground (neutral), and with both PAN and TILT motors operating simultaneously.

2.For 24 VAC Models operating at or near

3.3Wall Mounting

Follow the instructions provided with mounts. Mount and mounting surface must be able to support the weight of the pan/tilt, camera/lens, and enclosure (if used). The camera/lens/enclosure must be properly mounted and balanced on the pan/tilt bracket.

Caution: The pan/tilts can only be mounted upright or inverted; never horizontally.

3.4Camera/Lens/Enclosure Mounting

Mount the camera/lens/enclosure to the pan/tilt bracket as follows:

1.Balance the camera/lens/enclosure and adjust unit to align with mounting holes. Fasten with a minimum of two

(2)

2.Make all electrical connections. Leave sufficient loops of cable between camera/enclosure and pan/tilt to allow for tilting and panning.

3.5Electrical Connections

1.Cable must be wired according to Connector Assembly (Section 3.7) and Recommended Maximum Cable Lengths (Table 1).

2.Use separate shielded cables for camera power, enclosure power, and pan/tilt control. If required, combining lens control wiring and video coax within a common cable is acceptable. The use of a common multiconductor cable to combine all functions is not recommended.

3.Use color coded conductors to aid wiring and future identification.

AMP Hand Crimping Tool

Caution: Contact removal from connector requires use of AMP #305183 extraction tool.

3.6Grounding Connection

A ground screw is located on the base to the right of connector. See Figure 8. Connect a 1 mm2 (No.18 AWG) ground wire to the nearest earth ground.

3.7Connector Assembly

A mating connector, sockets and a strain relief are included with the unit. See Figure 1.

To install, select the appropriate size strain relief clamp. Choose one of the two strain relief clamps enclosed with the sleeve and the extender. The clamping area is adjustable by inverting or changing the strain relief clamps. Discard the four strain reliefs on the carrier strip packaged with the shield.

Insert the clamp into the strain relief until it bottoms. The clamp should bottom on the wire bundle, not on the shield’s shoulder. If the wire diameter is too small, temporarily wrap the wire with electrical tape until proper clamping is obtained. Secure the clamp with the two (2) screws provided.

Caution: Make sure the wire bundle is properly secured. Do NOT pinch the wires.

5