Document

Installation and Operation Instructions

Installation and Operation Instructions for

BRUTE ELITE

Brute Elite Control Setup and Operation

TABLE OF CONTENTS

SECTION

General Information

Trouble Shooting

SECTION Maintenance

Replacement Parts

SECTION Modes of Operation

1.1 Introduction

SECTION General Information

1.2 Model Identification

Model Nomenclature

Figure 2. Location of Components, Sizes

Figure 1. Location of Components, Sizes

Figure 4. Location of Components, Size

Figure 3. Location of Components, Size

Figure 6. Location of Components, Size

Figure 5. Location of Components, Size

Figure 7. Location of Components, Sizes 750 and

1.6 Dimensions

1.4 Warranty

1.3 Appliance Overview

1.5 Unpacking

Dimensions are nominal and are shown in inches, cm

Figure 9. Dimensional Drawing, Sizes

Brute Elite is for indoor installations only

SECTION Locating the Appliance

2.1 Locating the Appliance

3.1 Combustion Air

SECTION Venting and Combustion Air

3.1.1 Combustion Air From Room

3.1.2 Ducted Combustion Air

3.2 Venting

Figure 10. Combustion Air and Vent Through Roof

Table 5. Required Exhaust Vent Material

3.2.1 Venting Requirements Unique to Canada

3.3 Locating Vent & Combustion Air Terminals

A. exhaust vent terminal not included

E. CPVC exhaust pipe section 80-500 not incl

3.3.2 Side Wall Combustion Air Terminal

3.3.5 Installations in the Commonwealth of Massachusetts

5. For concentric vent, follow instructions included with vent kit

3.3.3 Vertical Vent Terminal

Figure 12. Combustion Air and Vent Through Side Wall

2. Approved Carbon Monoxide Detectors

3.4 Common Vent Test

3. Signage

4. Inspection

SECTION Gas Supply and Piping

4.1 Gas Supply and Piping

3. Refer to Tables 6A, 6B, 6C and 6D to size piping

5.1 Brute Elite Boiler Flow and Head Requirements see Table

SECTION Pump Requirements

5.2 Brute Elite Water Heater Flow and Head Requirements see Table

Table 6A

SECTION 6A Water Connections - BNTH Boiler

6A.1 BNTH System Piping Hot Supply Connections

6A.2 BNTH Cold Water Make-Up

6A.3 Freeze Protection

6A.4 BNTH Suggested Piping Schematics

6A.5 Recognized Chemicals

1. Sentinel Performance Solutions Group 2. Hercules Chemical Company

Figure 15. Hydronic Piping - Single Boiler zoning with circulators

Page

Figure 17. Hydronic Piping - Multiple Boilers zoning with circulators

Page

Brute Elite

Page

Page

Brute Elite

Page

6B.1 BNTV Water Quality

SECTION 6B

6B.2 Piping Requirements

Water Connections - BNTV Water Heater

6B.3 Cold Water Make-Up

6B.5 BNTV Suggested Piping Schematics

6B.4 Freeze Protection

6B.6 BNTV Suggested Pumps

Figure 26. DHW Piping, Two Heaters, Two Vertical Tanks

Figure 25. DHW Piping, Two Heaters, One Vertical Tank

Caution Pump sizing must be based opon

water hardness at job site

SECTION Electrical Connections

7.1 Main Power

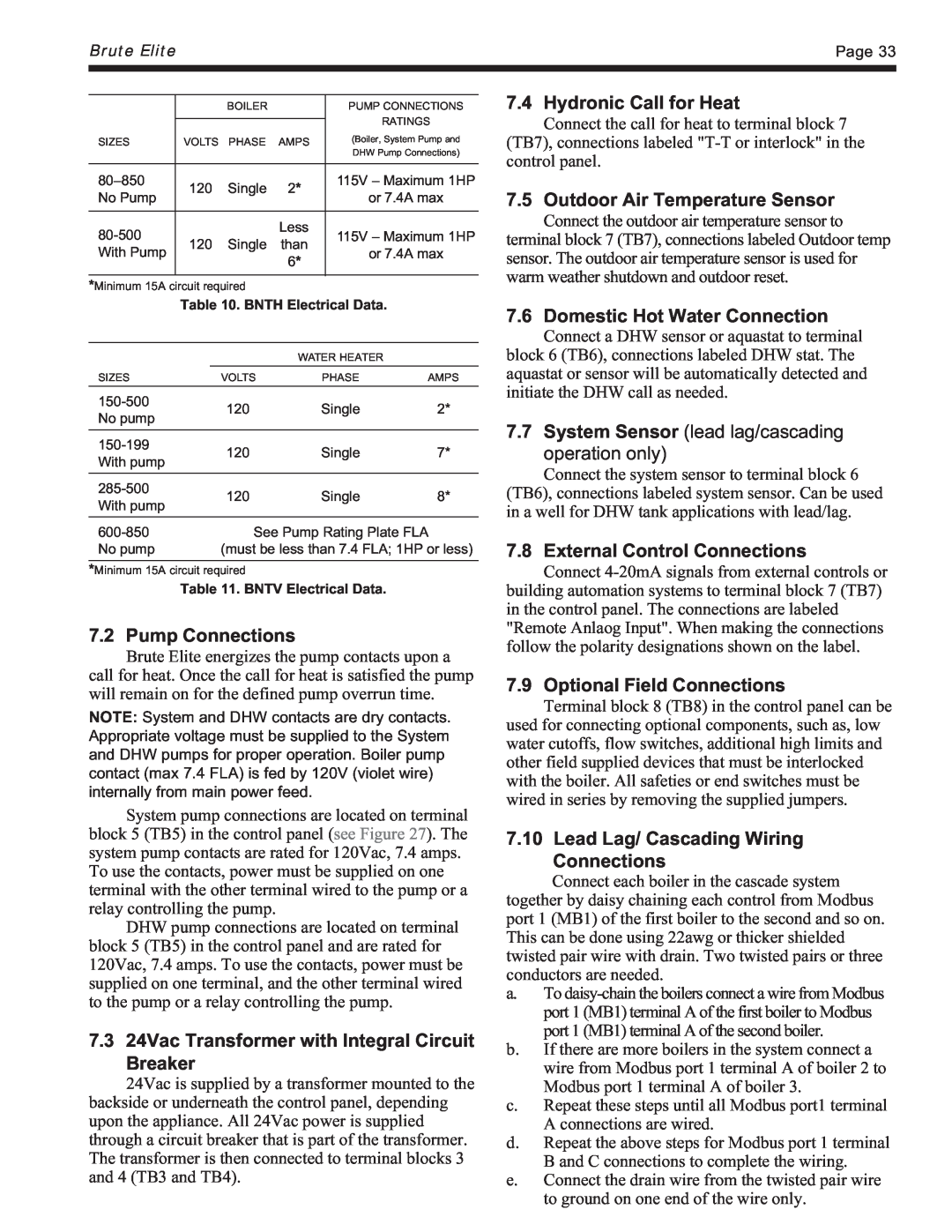

7.2 Pump Connections

7.10 Lead Lag/ Cascading Wiring Connections

7.3 24Vac Transformer with Integral Circuit Breaker

7.4 Hydronic Call for Heat

Figure 28. Lead-Lag / Cascading Wiring Connections

Figure 29. Ladder Diagram

7.11 Wiring Diagrams see Figures 29 and

Figure 30. Wiring Diagram all sizes

SECTION Brute Elite Control Setup and Operation

8.1 Display Navigation

8.2 Ignition Control- Sequence of Events

8.5 Anti-Short Cycle ASC

8.3 Modulation Control

8.5 High Limit

8.7 Outlet Water Temperature

8.13 Boiler Pump Interrupt

8.12.5 Lead Lag Base Load Setting

8.12.1 Lead Lag Setpoint

8.12.2 Lead Lag Master/Slave Selection

9.4 Hydronic Heating Using External Modulation Control

9.2 Hydronic Heating with Outdoor Reset

SECTION Modes of Operation

9.1 Hydronic Heating Demand

9.7 Warm Weather Shutdown

9.5 Hydronic Heating Using Local Lead- Lag/Cascading Feature

9.8 Domestic Hot Water Demand BNTV only

Let’s consider the following example

9.9 Domestic Hot Water Heating Using External Modulation Control

SECTION Operating Instructions

10.2 Operating the Burner and Set Up

10.1 Filling the Boiler System

10.2.1 Burner Operation

10.3 Shutting Down Brute Elite

10.2.2 Boiler Setup and Adjustment

10.4 To Restart Brute Elite

3. WAIT FIVE 5 MINUTES

80-285

Figure 33A. Brute Elite Gas Valves 285, 399 and

Figure 33B. Brute Elite Gas Valves 600, 750 and

11.1 System Maintenance

SECTION Maintenance

11.2 Appliance Maintenance and Component Description

yearly, unless otherwise noted

11.2.4 Ignitor Assembly

11.2.5 Flame Sensor

Igniters and sensors get hot and can cause burns or injury

11.2.6 Transformer with Integral Circuit Breaker

11.2.7 Blower

11.2.8 Heat Exchanger Coils

12.3 Error Codes - See Table

SECTION Trouble Shooting

11.2.9 Gas Pressure Switches optional

12.1 Sequence of Operation

SOLUTION

PROBLEM

continued next page

CODE#

see Section

Table 18. Error Codes

13.2 Parts List

SECTION Replacement Parts

13.1 General Information

Jacket Components - See Figure

Gas Train Components - See Figure

Heat Exchanger Components - See Figure

Electrical Components - See Figure

Contact Customer Service at 800 900-9275

Figure 35. Jacket Components

Figure 36B. Internal Components, Sizes

Figure 36A. Internal Components, Sizes

Figure 36C. Internal Components, Sizes

Figure 37A. Gas Train Components, Sizes

Figure 37B. Gas Train Components, Sizes

Figure 38. Heat Exchanger Components

Figure 39. Electrical Components

Page

Service Parts 800

Tech. Service 800

Warranty Service 800

Ambler, PA