581B,C

Compressor Rotation

On

1.Connect the service gauges to suction and discharge pressure fittings.

2.Energize the compressor.

3.The suction pressure should drop and the discharge pressure should rise, as is normal on any

If the suction pressure does not drop and the discharge pressure does not rise to normal levels:

1.Note that the indoor fan (006 and 007

2.Turn off power to the unit and tag disconnect.

3.Reverse any two of the unit power leads.

4.Turn on power to the unit and energize the compressor.

The suction and discharge pressure levels should now move to their normal

NOTE: When the compressor is rotating in the wrong direction, the unit makes more noise and does not provide cooling.

Cooling

Set the space thermostat to the OFF position. Set the system selector switch at COOL position and the fan switch at AUTO position. Adjust the thermostat to a setting below room temperature. The compressor starts when contactor closes.

Check the unit charge. Refer to Refrigerant Charge section.

Reset the thermostat at a position above room temperature. The compressor will shut off. Evaporator fan will shut off after a

To Shut Off Unit - Set the system selector switch at OFF position. Resetting the thermostat at a position above room temperature shuts off the unit temporarily until the space temperature exceeds the thermostat setting. Units are equipped with a

Main Burners

Main burners are factory set and should require no adjustment.

TO CHECK ignition of main burners and heating controls, move thermostat set point above room temperature and verify that the burners light and evaporator fan is energized. Check heating effect, then lower the thermostat setting below the room temperature and verify that the burners and evaporator fan turn off.

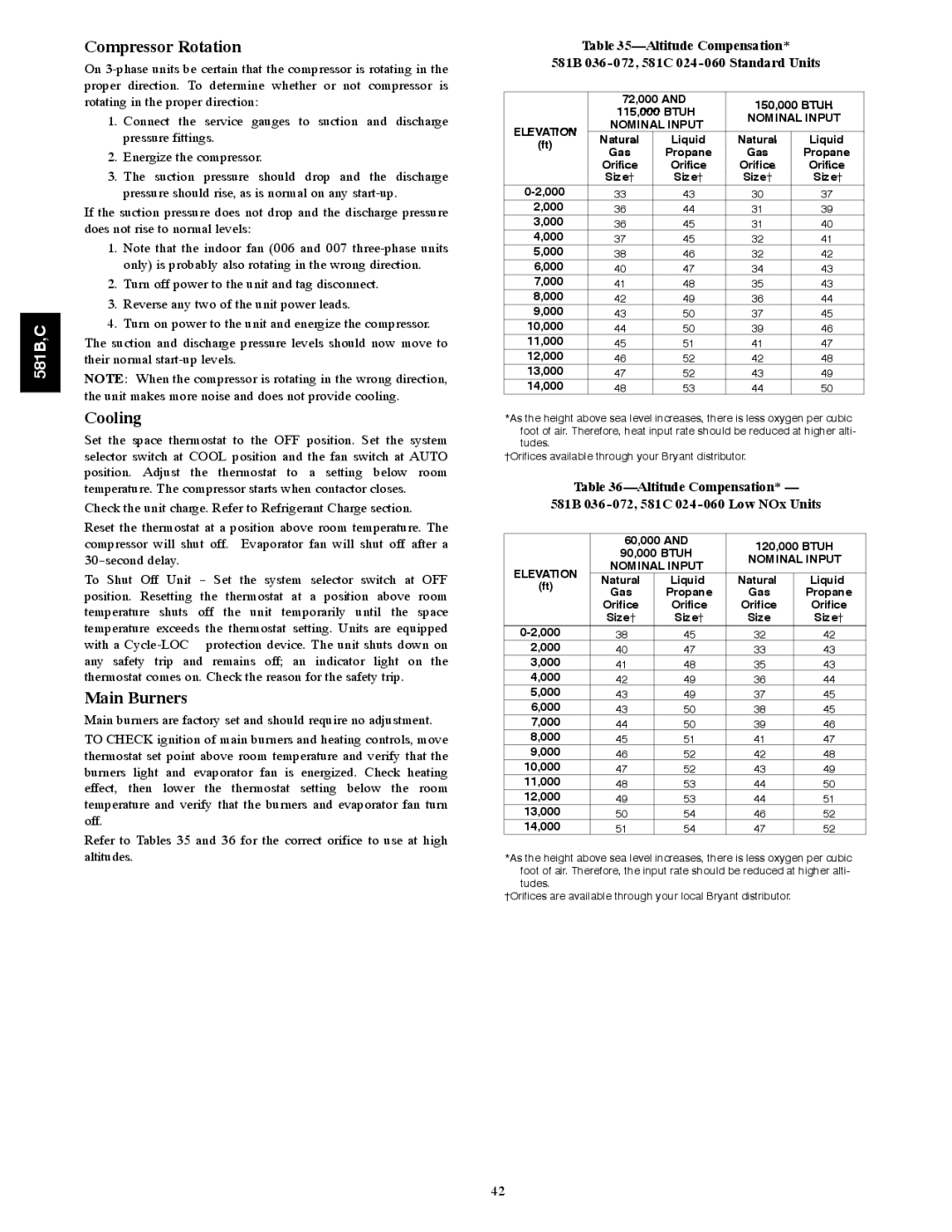

Refer to Tables 35 and 36 for the correct orifice to use at high altitudes.

Table

581B

| 72,000 AND | 150,000 BTUH | |||

| 115,000 BTUH | ||||

| NOMINAL INPUT | ||||

ELEVATION | NOMINAL INPUT | ||||

|

| ||||

(ft) | Natural | Liquid | Natural | Liquid | |

Gas | Propane | Gas | Propane | ||

| |||||

| Orifice | Orifice | Orifice | Orifice | |

| Size† | Size† | Size† | Size† | |

33 | 43 | 30 | 37 | ||

2,000 | 36 | 44 | 31 | 39 | |

3,000 | 36 | 45 | 31 | 40 | |

4,000 | 37 | 45 | 32 | 41 | |

5,000 | 38 | 46 | 32 | 42 | |

6,000 | 40 | 47 | 34 | 43 | |

7,000 | 41 | 48 | 35 | 43 | |

8,000 | 42 | 49 | 36 | 44 | |

9,000 | 43 | 50 | 37 | 45 | |

10,000 | 44 | 50 | 39 | 46 | |

11,000 | 45 | 51 | 41 | 47 | |

12,000 | 46 | 52 | 42 | 48 | |

13,000 | 47 | 52 | 43 | 49 | |

14,000 | 48 | 53 | 44 | 50 | |

*As the height above sea level increases, there is less oxygen per cubic foot of air. Therefore, heat input rate should be reduced at higher alti- tudes.

†Orifices available through your Bryant distributor.

Table

581B

| 60,000 AND | 120,000 BTUH | |||

| 90,000 BTUH | ||||

| NOMINAL INPUT | ||||

| NOMINAL INPUT | ||||

ELEVATION |

|

| |||

(ft) | Natural | Liquid | Natural | Liquid | |

Gas | Propane | Gas | Propane | ||

| |||||

| Orifice | Orifice | Orifice | Orifice | |

| Size† | Size† | Size | Size† | |

38 | 45 | 32 | 42 | ||

2,000 | 40 | 47 | 33 | 43 | |

3,000 | 41 | 48 | 35 | 43 | |

4,000 | 42 | 49 | 36 | 44 | |

5,000 | 43 | 49 | 37 | 45 | |

6,000 | 43 | 50 | 38 | 45 | |

7,000 | 44 | 50 | 39 | 46 | |

8,000 | 45 | 51 | 41 | 47 | |

9,000 | 46 | 52 | 42 | 48 | |

10,000 | 47 | 52 | 43 | 49 | |

11,000 | 48 | 53 | 44 | 50 | |

12,000 | 49 | 53 | 44 | 51 | |

13,000 | 50 | 54 | 46 | 52 | |

14,000 | 51 | 54 | 47 | 52 | |

*As the height above sea level increases, there is less oxygen per cubic foot of air. Therefore, the input rate should be reduced at higher alti- tudes.

†Orifices are available through your local Bryant distributor.

42