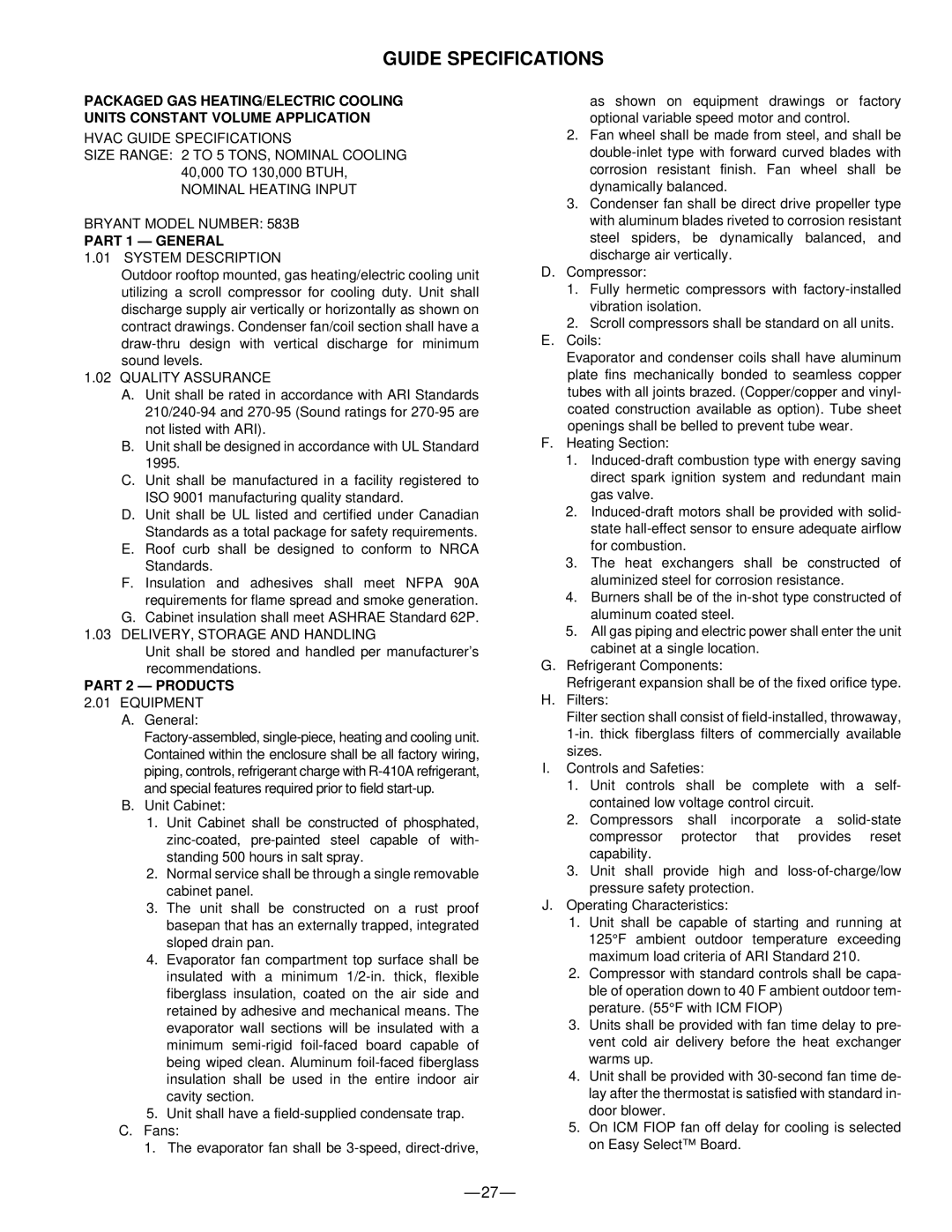

PACKAGED GAS HEATING/ELECTRIC COOLING UNITS CONSTANT VOLUME APPLICATION

HVAC GUIDE SPECIFICATIONS

SIZE RANGE: 2 TO 5 TONS, NOMINAL COOLING 40,000 TO 130,000 BTUH,

NOMINAL HEATING INPUT

BRYANT MODEL NUMBER: 583B

PART 1 — GENERAL

1.01 SYSTEM DESCRIPTION

Outdoor rooftop mounted, gas heating/electric cooling unit utilizing a scroll compressor for cooling duty. Unit shall discharge supply air vertically or horizontally as shown on contract drawings. Condenser fan/coil section shall have a draw-thru design with vertical discharge for minimum sound levels.

1.02QUALITY ASSURANCE

A.Unit shall be rated in accordance with ARI Standards 210/240-94 and 270-95 (Sound ratings for 270-95 are not listed with ARI).

B.Unit shall be designed in accordance with UL Standard 1995.

C.Unit shall be manufactured in a facility registered to ISO 9001 manufacturing quality standard.

D.Unit shall be UL listed and certified under Canadian Standards as a total package for safety requirements.

E.Roof curb shall be designed to conform to NRCA Standards.

F.Insulation and adhesives shall meet NFPA 90A requirements for flame spread and smoke generation.

G.Cabinet insulation shall meet ASHRAE Standard 62P.

1.03DELIVERY, STORAGE AND HANDLING

Unit shall be stored and handled per manufacturer’s recommendations.

PART 2 — PRODUCTS

2.01EQUIPMENT

A.General:

Factory-assembled, single-piece, heating and cooling unit. Contained within the enclosure shall be all factory wiring, piping, controls, refrigerant charge with R-410A refrigerant, and special features required prior to field start-up.

B.Unit Cabinet:

1.Unit Cabinet shall be constructed of phosphated, zinc-coated, pre-painted steel capable of with- standing 500 hours in salt spray.

2.Normal service shall be through a single removable cabinet panel.

3.The unit shall be constructed on a rust proof basepan that has an externally trapped, integrated sloped drain pan.

4.Evaporator fan compartment top surface shall be insulated with a minimum 1/2-in. thick, flexible fiberglass insulation, coated on the air side and retained by adhesive and mechanical means. The evaporator wall sections will be insulated with a minimum semi-rigid foil-faced board capable of being wiped clean. Aluminum foil-faced fiberglass insulation shall be used in the entire indoor air cavity section.

5.Unit shall have a field-supplied condensate trap. C. Fans:

1.The evaporator fan shall be 3-speed, direct-drive,

as shown on equipment drawings or factory optional variable speed motor and control.

2.Fan wheel shall be made from steel, and shall be double-inlet type with forward curved blades with corrosion resistant finish. Fan wheel shall be dynamically balanced.

3.Condenser fan shall be direct drive propeller type with aluminum blades riveted to corrosion resistant steel spiders, be dynamically balanced, and discharge air vertically.

D.Compressor:

1.Fully hermetic compressors with factory-installed vibration isolation.

2.Scroll compressors shall be standard on all units.

E.Coils:

Evaporator and condenser coils shall have aluminum plate fins mechanically bonded to seamless copper tubes with all joints brazed. (Copper/copper and vinyl- coated construction available as option). Tube sheet openings shall be belled to prevent tube wear.

F.Heating Section:

1.Induced-draft combustion type with energy saving direct spark ignition system and redundant main gas valve.

2.Induced-draft motors shall be provided with solid- state hall-effect sensor to ensure adequate airflow for combustion.

3.The heat exchangers shall be constructed of aluminized steel for corrosion resistance.

4.Burners shall be of the in-shot type constructed of aluminum coated steel.

5.All gas piping and electric power shall enter the unit cabinet at a single location.

G.Refrigerant Components:

Refrigerant expansion shall be of the fixed orifice type.

H.Filters:

Filter section shall consist of field-installed, throwaway, 1-in. thick fiberglass filters of commercially available sizes.

I.Controls and Safeties:

1.Unit controls shall be complete with a self- contained low voltage control circuit.

2.Compressors shall incorporate a solid-state compressor protector that provides reset capability.

3.Unit shall provide high and loss-of-charge/low pressure safety protection.

J.Operating Characteristics:

1.Unit shall be capable of starting and running at 125°F ambient outdoor temperature exceeding maximum load criteria of ARI Standard 210.

2.Compressor with standard controls shall be capa- ble of operation down to 40 F ambient outdoor tem- perature. (55°F with ICM FIOP)

3.Units shall be provided with fan time delay to pre- vent cold air delivery before the heat exchanger warms up.

4.Unit shall be provided with 30-second fan time de- lay after the thermostat is satisfied with standard in- door blower.

5.On ICM FIOP fan off delay for cooling is selected on Easy Select™ Board.