Table 7: Maximum Capacity of Schedule 40 Pipe in CFH* For natural Gas Pressures of 0.5 psig or Less

Length |

| 0.3 Inch w.c. Pressure Drop |

|

| 0.5 Inch w.c. Pressure Drop |

| ||||||

[Feet] | ½ |

| ¾ | 1 |

| 1¼ | ½ |

| ¾ | 1 |

| 1¼ |

10 | 132 |

| 278 | 520 |

| 1,050 | 175 |

| 360 | 680 |

| 1,400 |

20 | 92 |

| 190 | 350 |

| 730 | 120 |

| 250 | 465 |

| 950 |

30 | 73 |

| 152 | 285 |

| 590 | 97 |

| 200 | 375 |

| 770 |

40 | 63 |

| 130 | 245 |

| 500 | 82 |

| 170 | 320 |

| 660 |

50 | 56 |

| 115 | 215 |

| 440 | 73 |

| 151 | 285 |

| 580 |

60 | 50 |

| 105 | 195 |

| 400 | 66 |

| 138 | 260 |

| 530 |

70 | 46 |

| 96 | 180 |

| 370 | 61 |

| 125 | 240 |

| 490 |

80 | 43 |

| 90 | 170 |

| 350 | 57 |

| 118 | 220 |

| 460 |

90 | 40 |

| 84 | 160 |

| 320 | 53 |

| 110 | 205 |

| 430 |

100 | 38 |

| 79 | 150 |

| 305 | 50 |

| 103 | 195 |

| 400 |

*1 CFH of Natural Gas is approximately equal to 1 MBH; 1 CFH of LP is approximately equal to 2.5 MBH; con- tact your gas supplier for the actual heating value of your gas.

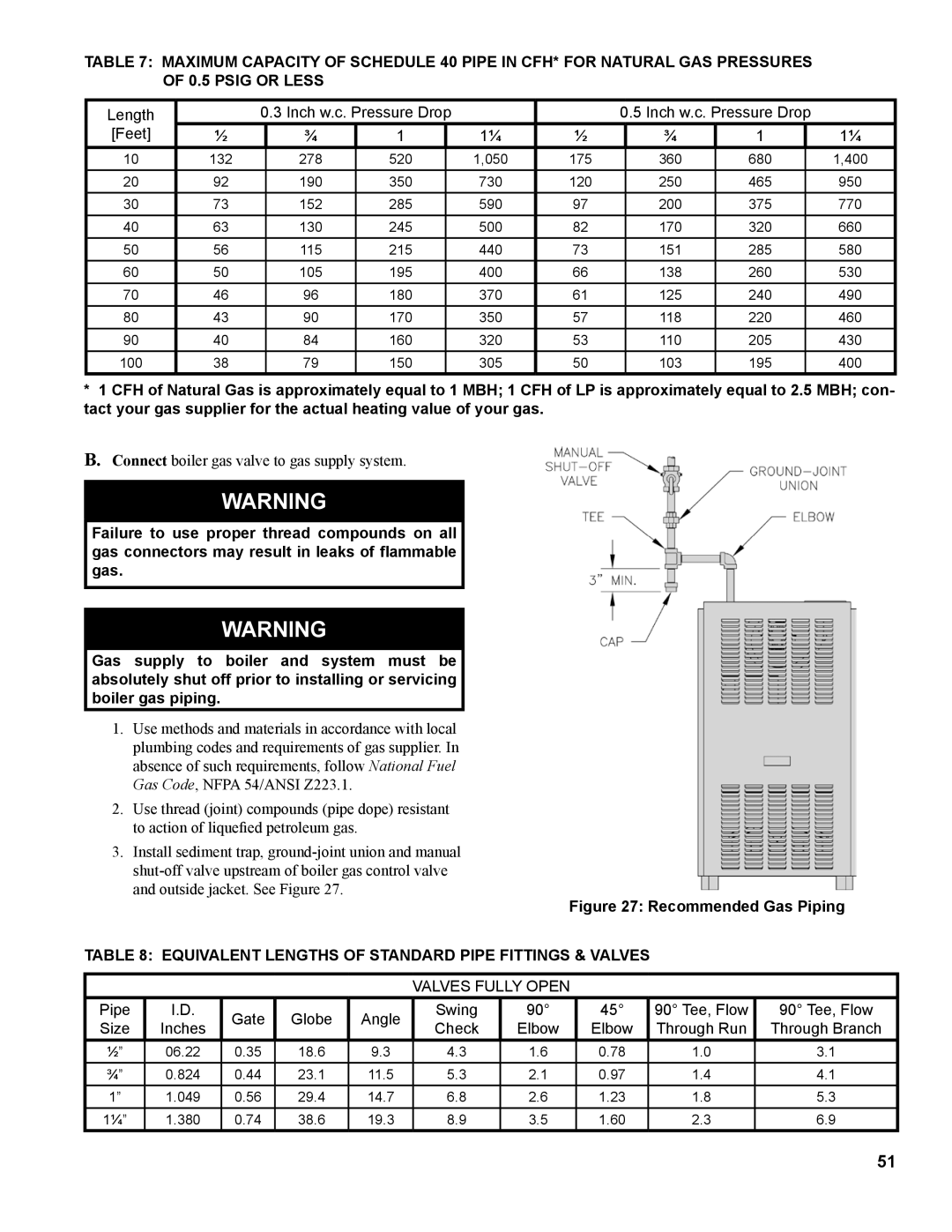

B.Connect boiler gas valve to gas supply system.

WARNING

Failure to use proper thread compounds on all gas connectors may result in leaks of flammable gas.

WARNING

Gas supply to boiler and system must be absolutely shut off prior to installing or servicing boiler gas piping.

1.Use methods and materials in accordance with local plumbing codes and requirements of gas supplier. In absence of such requirements, follow National Fuel Gas Code, NFPA 54/ANSI Z223.1.

2.Use thread (joint) compounds (pipe dope) resistant to action of liquefied petroleum gas.

3.Install sediment trap,

Figure 27: Recommended Gas Piping

Table 8: Equivalent Lengths of Standard Pipe Fittings & Valves

VALVES FULLY OPEN

Pipe | I.D. | Gate | Globe | Angle | Swing | 90° | 45° | 90° Tee, Flow | 90° Tee, Flow | |

Size | Inches | Check | Elbow | Elbow | Through Run | Through Branch | ||||

|

|

| ||||||||

½” | 06.22 | 0.35 | 18.6 | 9.3 | 4.3 | 1.6 | 0.78 | 1.0 | 3.1 | |

¾” | 0.824 | 0.44 | 23.1 | 11.5 | 5.3 | 2.1 | 0.97 | 1.4 | 4.1 | |

1” | 1.049 | 0.56 | 29.4 | 14.7 | 6.8 | 2.6 | 1.23 | 1.8 | 5.3 | |

1¼” | 1.380 | 0.74 | 38.6 | 19.3 | 8.9 | 3.5 | 1.60 | 2.3 | 6.9 |

51