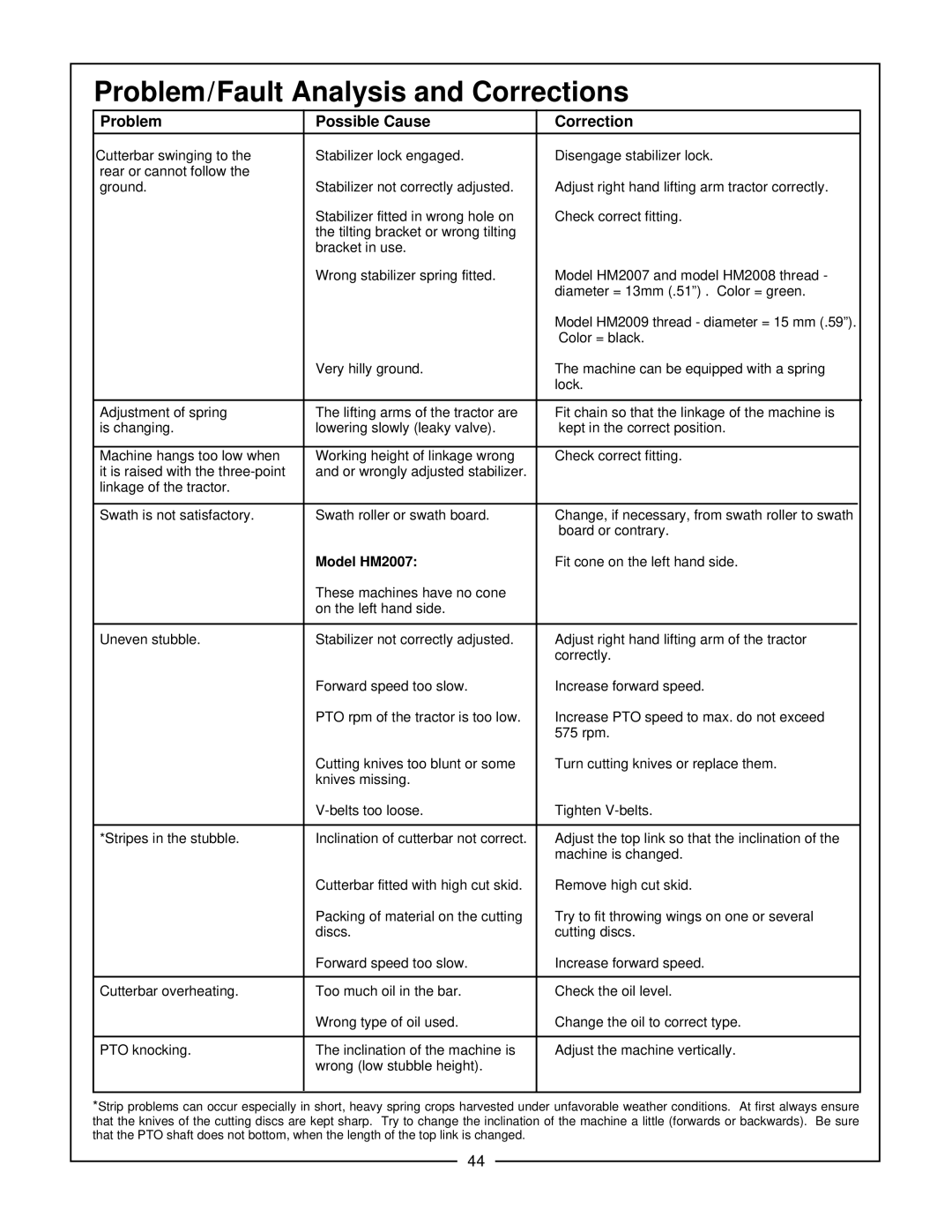

Problem/Fault Analysis and Corrections

Problem | Possible Cause | Correction | ||

|

|

|

|

|

Cutterbar swinging to the | Stabilizer lock engaged. | Disengage stabilizer lock. | ||

rear or cannot follow the |

|

|

|

|

ground. | Stabilizer not correctly adjusted. | Adjust right hand lifting arm tractor correctly. | ||

| Stabilizer fitted in wrong hole on | Check correct fitting. | ||

| the tilting bracket or wrong tilting |

|

|

|

| bracket in use. |

|

|

|

| Wrong stabilizer spring fitted. | Model HM2007 and model HM2008 thread - | ||

|

| diameter = 13mm (.51”) . Color = green. | ||

|

| Model HM2009 thread - diameter = 15 mm (.59”). | ||

|

| Color = black. | ||

| Very hilly ground. | The machine can be equipped with a spring | ||

|

| lock. | ||

|

|

|

|

|

Adjustment of spring | The lifting arms of the tractor are | Fit chain so that the linkage of the machine is | ||

is changing. | lowering slowly (leaky valve). | kept in the correct position. | ||

|

|

|

|

|

Machine hangs too low when | Working height of linkage wrong | Check correct fitting. |

| |

it is raised with the | and or wrongly adjusted stabilizer. |

|

|

|

linkage of the tractor. |

|

|

|

|

|

|

|

|

|

Swath is not satisfactory. | Swath roller or swath board. | Change, if necessary, from swath roller to swath | ||

|

| board or contrary. | ||

| Model HM2007: | Fit cone on the left hand side. | ||

| These machines have no cone |

|

|

|

| on the left hand side. |

|

|

|

|

|

|

| |

Uneven stubble. | Stabilizer not correctly adjusted. | Adjust right hand lifting arm of the tractor | ||

|

| correctly. | ||

| Forward speed too slow. | Increase forward speed. | ||

| PTO rpm of the tractor is too low. | Increase PTO speed to max. do not exceed | ||

|

| 575 rpm. | ||

| Cutting knives too blunt or some | Turn cutting knives or replace them. | ||

| knives missing. |

|

|

|

| Tighten | |||

|

|

| ||

*Stripes in the stubble. | Inclination of cutterbar not correct. | Adjust the top link so that the inclination of the | ||

|

| machine is changed. | ||

| Cutterbar fitted with high cut skid. | Remove high cut skid. | ||

| Packing of material on the cutting | Try to fit throwing wings on one or several | ||

| discs. | cutting discs. | ||

| Forward speed too slow. | Increase forward speed. | ||

|

|

| ||

Cutterbar overheating. | Too much oil in the bar. | Check the oil level. | ||

| Wrong type of oil used. | Change the oil to correct type. | ||

|

|

| ||

PTO knocking. | The inclination of the machine is | Adjust the machine vertically. | ||

| wrong (low stubble height). |

|

|

|

|

|

|

|

|

*Strip problems can occur especially in short, heavy spring crops harvested under unfavorable weather conditions. At first always ensure that the knives of the cutting discs are kept sharp. Try to change the inclination of the machine a little (forwards or backwards). Be sure that the PTO shaft does not bottom, when the length of the top link is changed.

44