Figure 2 | Three Point | ||

|

| Lift Hitch | |

“U” Bracke | t | ||

| |||

| |||

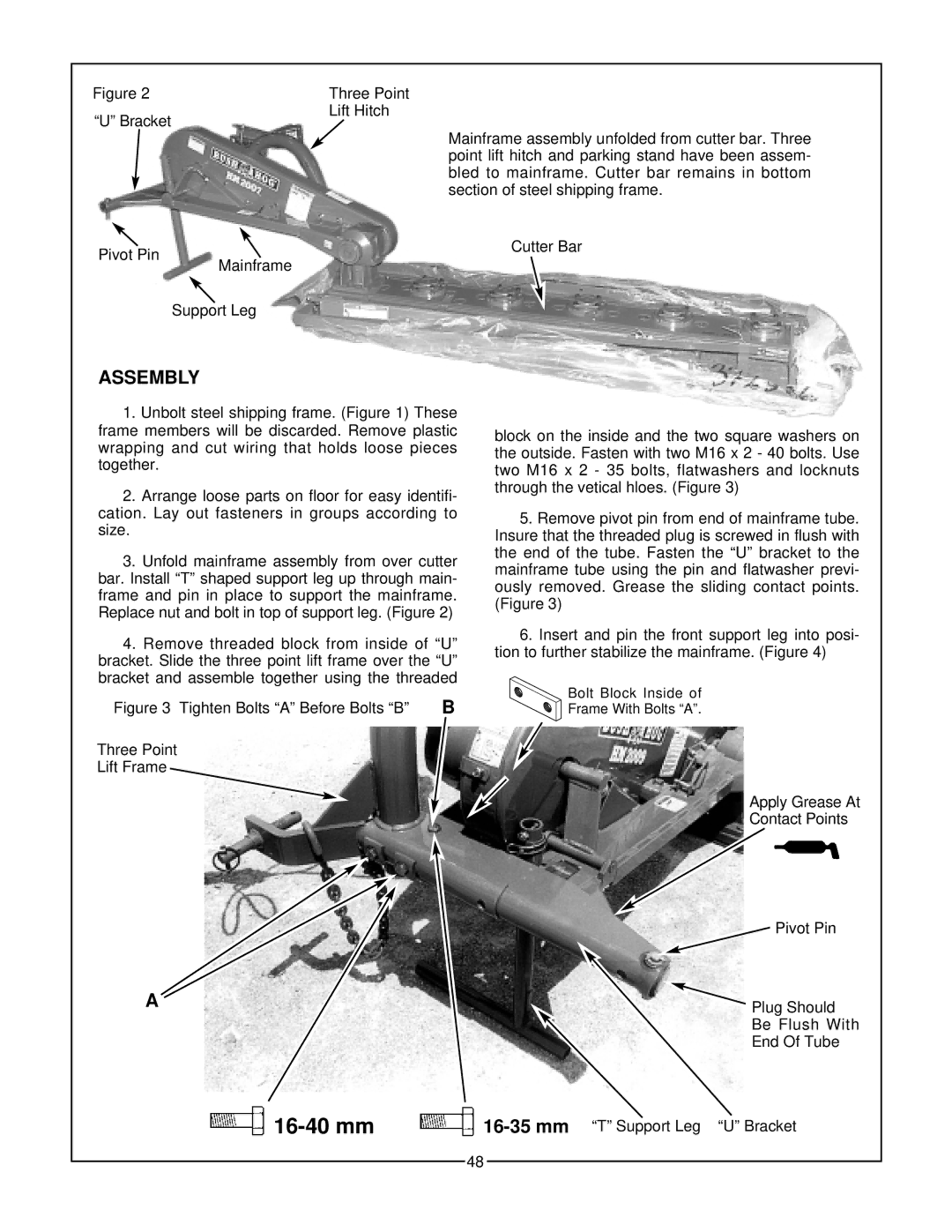

Mainframe assembly unfolded from cutter bar. Three point lift hitch and parking stand have been assem- bled to mainframe. Cutter bar remains in bottom section of steel shipping frame.

|

|

|

| Cutter Bar |

Pivot Pin |

| Mainframe | ||

|

| |||

|

|

| ||

|

|

| ||

|

|

|

|

|

|

| Support Leg | ||

|

|

|

|

|

ASSEMBLY

1.Unbolt steel shipping frame. (Figure 1) These frame members will be discarded. Remove plastic wrapping and cut wiring that holds loose pieces together.

2.Arrange loose parts on floor for easy identifi- cation. Lay out fasteners in groups according to size.

3.Unfold mainframe assembly from over cutter bar. Install “T” shaped support leg up through main- frame and pin in place to support the mainframe. Replace nut and bolt in top of support leg. (Figure 2)

4.Remove threaded block from inside of “U” bracket. Slide the three point lift frame over the “U” bracket and assemble together using the threaded

Figure 3 Tighten Bolts “A” Before Bolts “B” B

Three Point

Lift Frame

A

block on the inside and the two square washers on the outside. Fasten with two M16 x 2 - 40 bolts. Use two M16 x 2 - 35 bolts, flatwashers and locknuts through the vetical hloes. (Figure 3)

5.Remove pivot pin from end of mainframe tube. Insure that the threaded plug is screwed in flush with the end of the tube. Fasten the “U” bracket to the mainframe tube using the pin and flatwasher previ- ously removed. Grease the sliding contact points. (Figure 3)

6.Insert and pin the front support leg into posi- tion to further stabilize the mainframe. (Figure 4)

Bolt Block Inside of

Frame With Bolts “A”.

Apply Grease At

Contact Points

![]() Pivot Pin

Pivot Pin

![]() Plug Should

Plug Should

Be Flush With

End Of Tube

|

| “T” Support Leg “U” Bracket |

48