O | T2 C C O | DFT |

|

|

|

|

| OF2 | OF1 |

R | T1 |

|

|

|

|

|

|

|

|

W |

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

Y |

|

|

|

|

|

|

|

|

|

C | Y |

|

|

|

|

|

|

|

|

SPEEDUP | P1 |

|

|

|

|

|

|

|

|

J1 | P3 | INTERVALTIMER | 90 | 60 30 | 30 60 | 120 |

|

| |

| DFT |

| OFF |

| QUIET SHIFT | ON |

|

| |

| Speedup |

|

|

|

| Quiet | Defrost interval |

| |

| Pins |

|

|

|

| Shift | DIP switches |

| |

|

|

|

|

|

|

|

|

| A08020 |

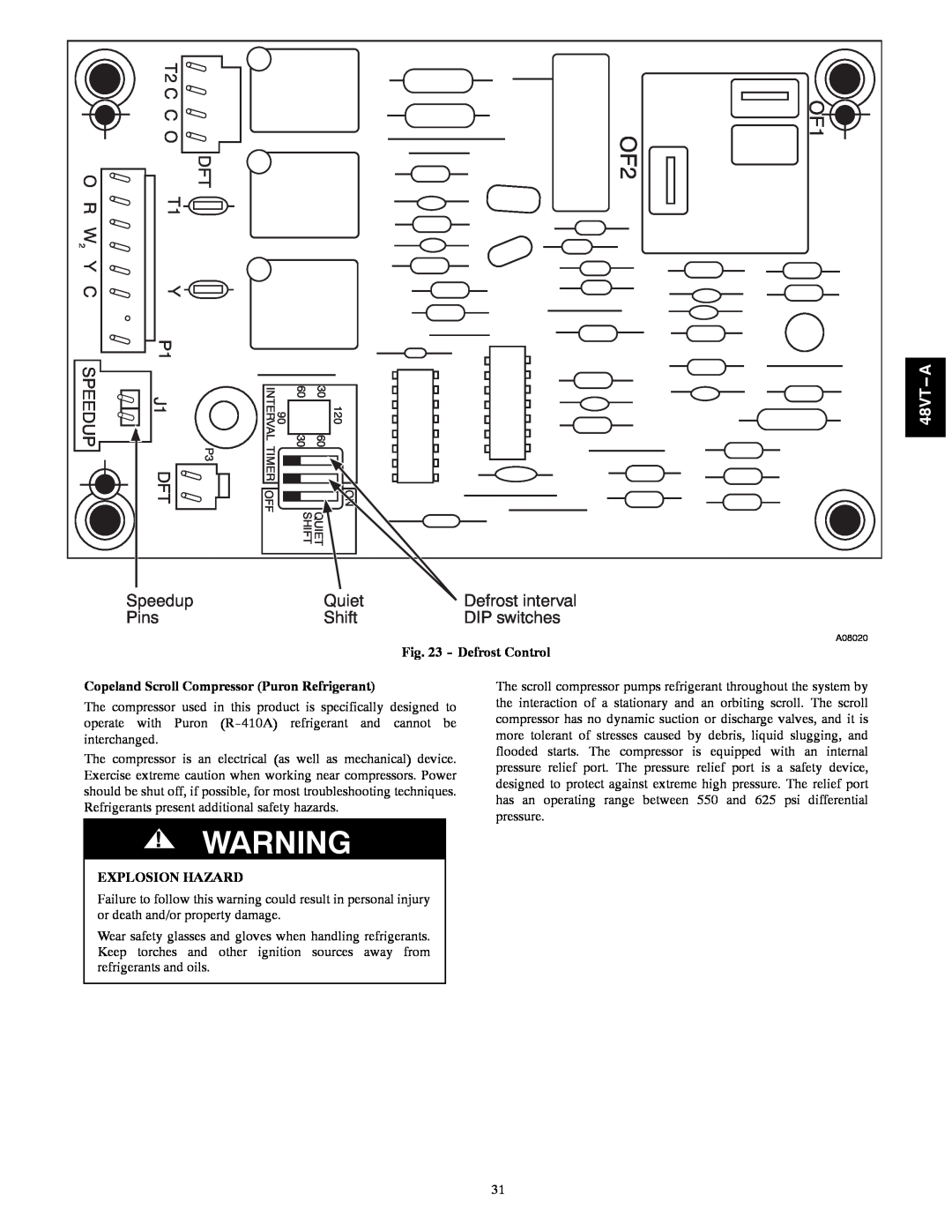

Fig. 23 - Defrost Control

Copeland Scroll Compressor (Puron Refrigerant)

The compressor used in this product is specifically designed to operate with Puron

The compressor is an electrical (as well as mechanical) device. Exercise extreme caution when working near compressors. Power should be shut off, if possible, for most troubleshooting techniques. Refrigerants present additional safety hazards.

!WARNING

EXPLOSION HAZARD

Failure to follow this warning could result in personal injury or death and/or property damage.

Wear safety glasses and gloves when handling refrigerants. Keep torches and other ignition sources away from refrigerants and oils.

The scroll compressor pumps refrigerant throughout the system by the interaction of a stationary and an orbiting scroll. The scroll compressor has no dynamic suction or discharge valves, and it is more tolerant of stresses caused by debris, liquid slugging, and flooded starts. The compressor is equipped with an internal pressure relief port. The pressure relief port is a safety device, designed to protect against extreme high pressure. The relief port has an operating range between 550 and 625 psi differential pressure.

31