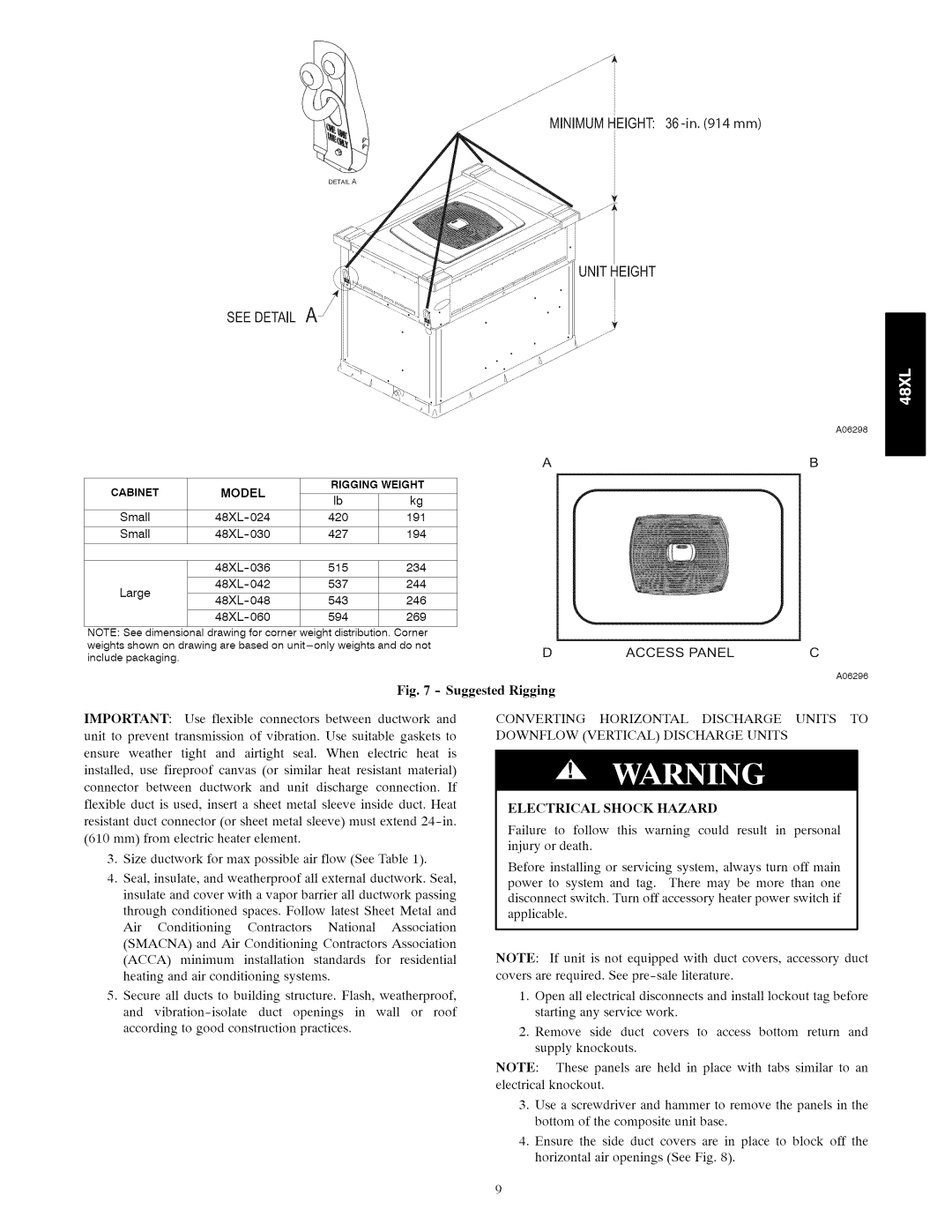

SEE DETAIL A /

CABINET | MODEL | RIGGING | WEIGHT | |

Ib | kg | |||

|

| |||

Small | 420 | 191 | ||

Small | 427 | 194 | ||

| 515 | 234 | ||

| 537 | 244 | ||

Large | 543 | 246 | ||

| 594 | 269 |

NOTE: See dimensional drawing for corner weight distribution. Corner weights shown on drawing are based on

UNITHEIGHT

A06298

A

J

DACCESS PANELC

A06296

Fig. 7 - Suggested

IMPORTANT: Use flexible connectors between ductwork and

unit to prevent transmission of vibration. Use suitable gaskets to

ensure weather tight and airtight seal. When electric heat is

installed, use fireproof canvas (or similar heat resistant material)

connector between ductwork and unit discharge connection. If flexible duct is used, insert a sheet metal sleeve inside duct. Heat

resistant duct connector (or sheet metal sleeve) must extend 24-in.

(610 mm) from electric heater element.

3.Size ductwork for max possible air flow (See Table 1).

4.Seal, insulate, and weatherproof all external ductwork. Seal,

insulate and cover with a vapor barrier all ductwork passing

through conditioned spaces. Follow latest Sheet Metal and

Air Conditioning Contractors National Association

(SMACNA) and Air Conditioning Contractors Association

(ACCA) minimum installation standards for residential

heating and air conditioning systems.

5.Secure all ducts to building structure. Flash, weatherproof,

and vibration-isolate duct openings in wall or roof

according to good construction practices.

Rigging

CONVERTING HORIZONTAL DISCHARGE UNITS TO

DOWNFLOW (VERTICAL) DISCHARGE UNITS

ELECTRICAL | SHOCK | HAZARD |

|

|

|

Failure to follow | this | warning could | result | in | personal |

iniury or death. |

|

|

|

|

|

Before installing | or servicing system, | always | turn | off main | |

power to system and tag. There may be more than one

disconnect switch. Turn off accessory heater power switch if applicable.

NOTE: If unit is not equipped with duct covers, accessory duct covers are required. See

1.Open all electrical disconnects and install lockout tag before starting any service work.

2.Remove side duct covers to access bottom return and supply knockouts.

NOTE: | These panels are held in place with tabs similar to an |

electrical | knockout. |

3.Use a screwdriver and hammer to remove the panels in the bottom of the composite unit base.

4.Ensure the side duct covers are in place to block off the horizontal air openings (See Fig. 8).