3.1.2Preventing Electrostatic Damage to Equipment

Many electronic components are sensitive to ESD. Circuitry design and structure determine the degree of sensitivity. The following proper packaging and grounding precautions are necessary to prevent damage to electric components and accessories.

!To avoid hand contact, transport products in

!Protect all electrostatic parts and assemblies with conductive or approved containers or packaging.

!Keep electrostatic sensitive parts in their containers until they arrive at

!Place items on a grounded surface before removing them from their container.

!Always be properly grounded when touching a sensitive component or assembly.

!Avoid contact with pins, leads, or circuitry.

!Place reusable

3.1.3Personal Grounding Methods and Equipment

Use the following equipment to prevent static electricity damage to equipment:

!Wrist straps are flexible straps with a minimum of

!Heel straps/Toe straps/Boot straps can be used at standing workstations and are compatible with most types of shoes or boots. On conductive floors or dissipative floor mats, use them on both feet with a minimum of

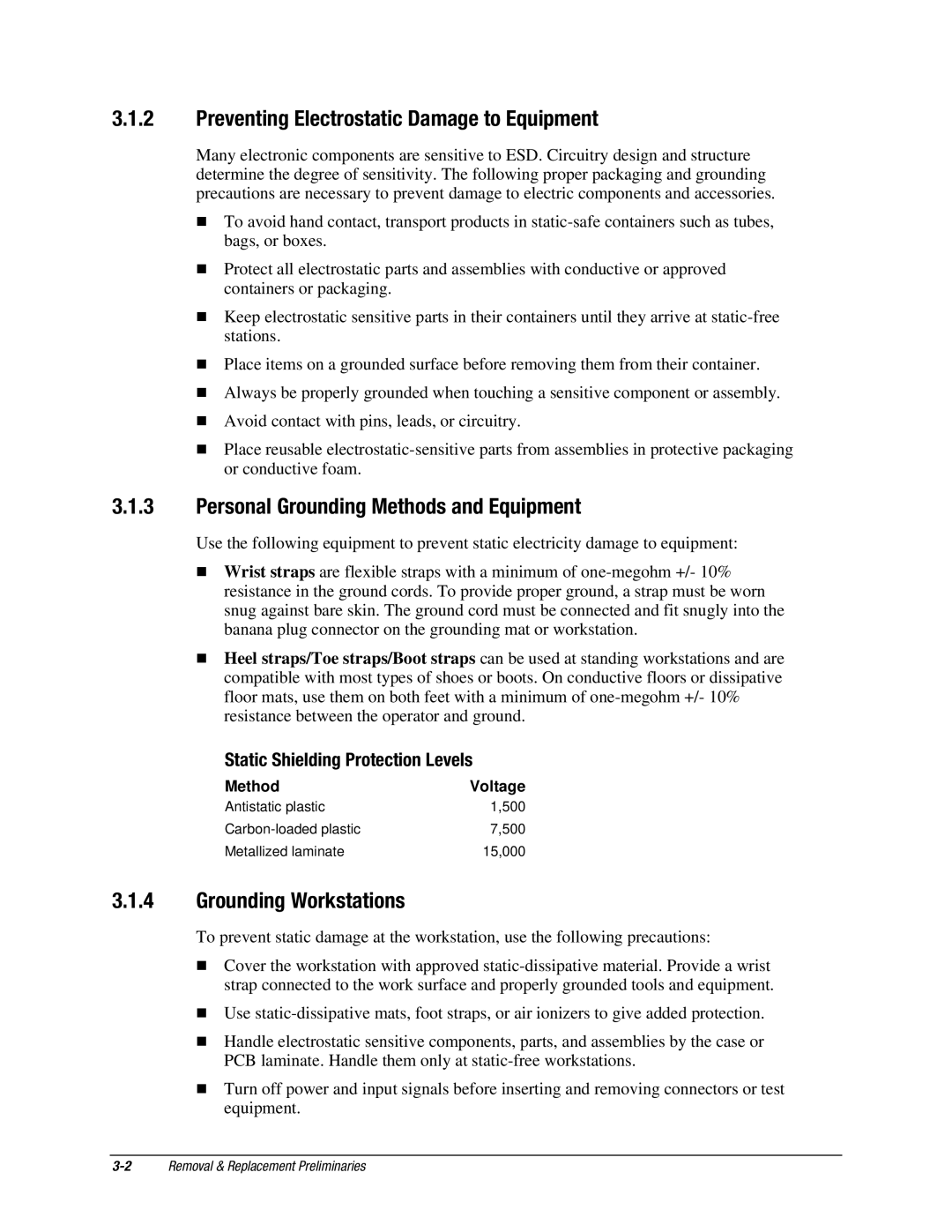

Static Shielding Protection Levels

Method | Voltage |

Antistatic plastic | 1,500 |

7,500 | |

Metallized laminate | 15,000 |

3.1.4Grounding Workstations

To prevent static damage at the workstation, use the following precautions:

!Cover the workstation with approved

!Use

!Handle electrostatic sensitive components, parts, and assemblies by the case or PCB laminate. Handle them only at

!Turn off power and input signals before inserting and removing connectors or test equipment.