Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A

Model No Safety

ESPANOL, p

Craftsman Full Warranty

Assembly Page10

ServiceNumbers BackPage Service&Maintenance

Page57

California Proposition

General Operation

Mufflerandenginebecomehotandcan causea burn.Do not touch

Followthe manufacturersrecommendationsfor wheelweights

Slope Operation

Do Not

Do notcoastdownhill

Service

Towing

Useonly anapprovedgasolinecontainer

Starting

GeneralService

NormaloperationAdjustandserviceasrequired

Extracautionwhenservicingthem

Safety Symbols

Read the Operatorsmanuals

#Old

Rotating Blades Cause

Tire Pressure

Attaching the Battery Cables

Opening the Tractor Hood

Sectionof thismanualthe Tractor

Meets Ansi Safety Standards

LCD Hour Meter Display

KEY Switch Module

Meter

Throttle Control Lever

Parking Brake Lever

Seat Adjustment Lever

Deck Lift Lever

IVT Infinitely Variable Transmission

OIL and GAS FILL-UP

Safety Interlock System

Reverse Caution Mode

0il

Starting the Engine

Stopping the Engine

Steering the Tractor

DRiViNG the Tractor

Driving on Slopes

Engaging the Parking Brake

Mowing

Moving the Tractor Manually

Engaging the PTO

Headlights

Midsteeringarms,pivot

Maintenance Schedule

Air filter

Replaceandtightendipstick

Checking the Engine Oil

OilDrain Il DrainValve Hose

Markonthedipstick

Addoilasdescribedabove

Leaks

StartandruntheengineAstheenginewarmsup,checkforoil

Electrode Porcelain

Lubrication

Battery

Cleaning Steering Gears

Cleaning the Tractor and Deck

Tires

Adjustments

Checking Main Harness Fuse

Eck

Adjustif necessaryas follows

Front To Rear Deck Leveling

Cutting Deck Removal

Slidea half inchflatwasher,witha maximumthicknessof

Bladesmayberemovedas follows

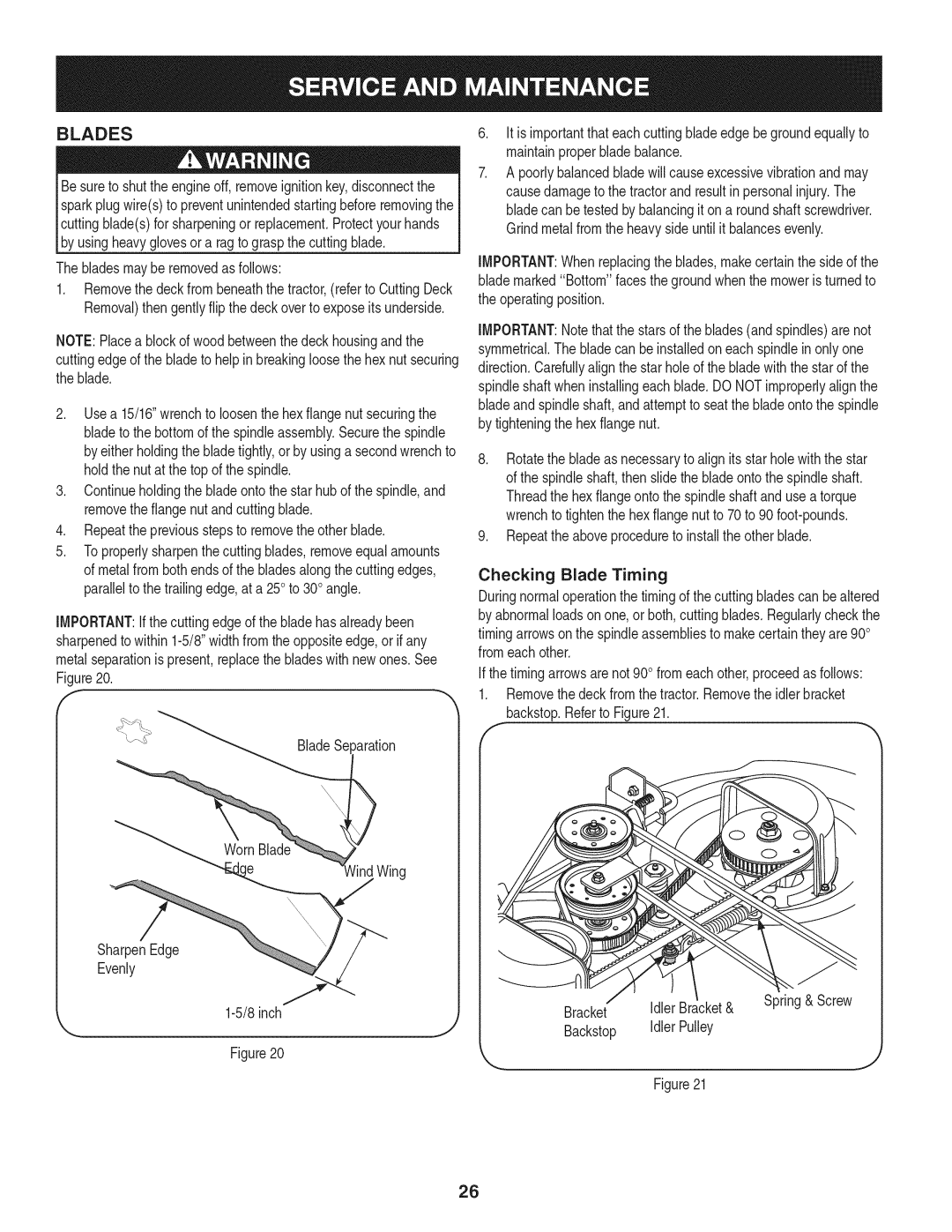

Blades

Besureto shutthe engineoff, removeignitionkey,disconnectthe

SharpenEdge Evenly 8inch Bracket Idler Bracket

Belts

Timing Belt

Pulley TimingArrow

PTOPulley PTOBelt

Reinstalling the Cutting Deck

Installthecuttingdeckas follows

Preparing the Engine

Preparing the Lawn Tractor

Maoage home

Replacefuel filter

Craftsman Revolution Model

Craftsman Revolution IViodel

712-04065

Craftsman Revolution IViodel 1024

Screw,Shoulder,.43x .29TT5/16-18

Craftsman Revolution IViodel

Washer,Fiat, .344x 1.0x .063 HT

Pad,FootLH

Washer,Fiat, .535x .93x

Bolt,Shoulder,.496x 2.53/8-16

Craftsman Revolution IViodel247.28933

683-04439

683-04440

Craftsman Revolution IViodel

33 -0626A

HoseClamp,.490Dia

85 -0227 Screw,Hd. lapp., #8-18x

Pin,3/16 x 3/4

FiatWasher,.330x .630x

Hose,Fuel LowPermeation,51inches

Craftsman Revolution Model \ /2

52 5O 3120

Fitting,Lube

Screw,Tri-Plask,1/4-10x

Pulley,Timing,56T

Bearing,Ball

850 11L4

Craftsman Engine Model 407777=0717=B1 For Revolution Model

883 617 1022 1026

15o ,S

Craftsman Engine Model407777-0717=B1For Revolution

163,£

Emissions Label

5Ol

1119U

698537 Valve-FloatNeedle

691001 Gasket-AirCleaner

694918 Pin-FloatHinge

792455 Kit-CarburetorOverhaul

691005 ScrewBlowerHousing 305A 790690

792028 Switch-OilPressure

796678 Housing-Blower

792105 Filter-AirCleanerCartridge

790544 Wire/Connector-Alternator 883 690970 Gasket-Exhaust

698330 Harness-Wiring

499602 Dipstick/TubeAssembly

792303 Filter-PreCleaner

Manufacturers Warranty Coverage

Suchdiagnosticworkisperformedatawarrantystation

Warrantystation

Arefranchisedtoservicethesubjectengines

OwnerSuchusewillnotreducethewarrantyobligationsofMTD

Moderate

GDOC-100182RevA

Page

Posterior

Combustible Gasolinasin plorno Bujia Champion RC12YC Motor

Estatentoa lacortadoray a la direcci6nde la descargade

Funcionaiviiento General

Elescapedel motordeesteproducto,algunosde suscornponentes

FUNCIONAiVlIENTO EN Pendientes

No hagaIo siguiente

Manejo seguro de la gasolina

Reiviolque

SERVIClO

Guardachispas

No Modifique EL Motor

AVlSO Referido a Emisiones

SilVlBOLOS DE Seguridad

Mireymantenc3aestehiveconunrbovertical

ERA

Apertura DEL Capo DEL Tractor

Instalacicn DE LOS Cables DE LA BAT

Proposkin 65 DE California

Cuchilla

Cumple con los estandares de seguridad de Ansi

Tap6ndeIlenadode combustible

Pantalla LCD del Medidor Horatio

Monitor Indicador DE SISTEMAS/MEDI

DOR Horario

Palanca DE Control DEL Regulador

Interruptor DE LA Potencia DE AR

Pedal DE Control DE Avance

Control DEL Obturador

Ranque Enganche DE Cuchilla Pedal Defreno

Visor DEL Nivel DE Combustible

Portacubeta

Palanca DE Ajuste DEL Asiento

MISI6N IVT Infinitamente Variable

SISTEIVlA DE Bloqueo DE Seguridad

Conduccion DEL Tractor

Encendido DEL Motor

Detention DEL Motor Importante

El motor,sueltela Ilave.VolverAa la posici6ndeCORTE

Operacisn EN Pendientes

Detenereltractor

Direccksn DEL Tractor

Conexisn DE Potencia DE Arranque PTO

Faros Delanteros

Corte DE Cesped

Movimiento Manual DEL Tractor

Coloqueel frenodernano Apagueelmotory retirela Ilave

Eldepuradordelfiltrode aire Lirnpie Filtrode aire

Lubrique

Plataforrna

Pivotey ejes

Curnplalatablaqueaparecea continuaci6n 32F Tt,,-Mb.s

Mantenimiento DE Motor

Comprobaci6n de Aceite del Motor

Tabla de viscosidad del aceite

Pestaa

Veala Figura9 Filtrode Aceite Pinza

De Lineas

ElectrodoPorceiana Separaci6n de 0.030 0.76mm

Lubricacion

Linipieza DEL Tractor Y DE LA Plata Forma

Limpieza DE LOS Engranajes DE LA

Direccion

Neumaticos

Cables Principal

BATERiA

Control DEL Fusible DEL Mazo DE

Carga de la bateria

Ajustes

Ataforrna plataforrnaj

Sobreel suelo,se lasdebebajar

Extraccion DE LA PLATAFORiVlA DE

Corte

Repitael procedirnientoanteriorparainstalarlaotra cuchilla

Cuchillas

Repitalos pasosanterioresparasacarlaotra cuchilla

Correas

Potenciade arranquePTO

VealaFigura21

CornoseindicaenlaFigura23

Zaci6nizquierda

Reinstalacion DE LA Plataforma DE Corte

Correa de transmisi6n

Lleneel dep6sitodecombustibleconcombustibletratadoy haga

Preparacion DEL Motor

Preparacksn DE LA Tractor DE Cesped

En lineaque seencuentracercadelmotor

Managehom÷

Unapasadadecorte rn.angosta

El motorfuncionacon Bujiaatorada,averiadaoexcesode

Depurador

Cobertura DE LA Garantja DEL Fabricante

Programaticpuntualparaesapieza

Cuesti6n

GDOC-100182Rev.A

Servicio de instalaci6nde Sears

Page

Page

Call anytime, day or night U.S.A. and Canada

LE-FOYER M

SU-HOGAR

CRRFr MRN

SAE30

California Proposition

Slope Operation

Children

GeneralService

Safety Symbols

#Old

Rotating Blades Cause

California Proposition

Meets Ansi Safety Standards

Meter

PTO

Gasoline

Starting the Engine

DRiViNG the Tractor

Moving the Tractor Manually

Maintenance Schedule

Engine Maintenance

Addoilasdescribedabove

Electrode Porcelain

Tires

Adjustments

Front To Rear Deck Leveling

Cutting Deck Removal

Blades

Belts

Pulley TimingArrow

Reinstalling the Cutting Deck

Preparing the Engine

Need More HELP?

Craftsman Revolution Model

Craftsman Revolution IViodel

Craftsman Revolution IViodel 1024

Craftsman Revolution Model

Craftsman Revolution IViodel

Pad,FootLH

Craftsman Revolution IViodel247.28933

683-04439

Craftsman Revolution IViodel

33 -0626A

85 -0227 Screw,Hd. lapp., #8-18x

Hose,Fuel LowPermeation,51inches

Craftsman Revolution Model \ /2

Screw,Tri-Plask,1/4-10x

850 11L4

883 617 1022 1026

Craftsman Engine Model407777-0717=B1For Revolution

Emissions Label

5Ol

694918 Pin-FloatHinge

841026 Cup-Governor

793145 Bracket-FuelPump

Manufacturers Warranty Coverage

Warrantystation

Moderate

Page

SAE30

Funcionaiviiento General

FUNCIONAiVlIENTO EN Pendientes

Reiviolque

Guardachispas

SilVlBOLOS DE Seguridad

Mireymantenc3aestehiveconunrbovertical

Apertura DEL Capo DEL Tractor

Cumple con los estandares de seguridad de Ansi

Monitor Indicador DE SISTEMAS/MEDI

Ranque Enganche DE Cuchilla Pedal Defreno

Portacubeta

Atras

Encendido DEL Motor

Figura5

Corte DE Cesped

Lista DE iVlANTENllVllENTO

Mantenimiento DE Motor

Figura8

Lubricacion

Direccion

Cables Principal

Ajustes

Ataforrna plataforrnaj

Corte

Cuchillas

Correas

CornoseindicaenlaFigura23

Reinstalacion DE LA Plataforma DE Corte

Preparacion DEL Motor

Managehom÷

Iiii!il

Cobertura DE LA Garantja DEL Fabricante

Programaticpuntualparaesapieza

GDOC-100182Rev.A

Servicio de instalaci6nde Sears

Page

Page

MY-HOME