MECHANICAL ADJUSTMENT (CONTINUED)

d.Make sure that the triangular mark “A” of the L LOAD- ING Ass’y is aligned with the mark “b” of the R LOAD- ING Ass’y. (Fig. 4.4)

e.Reference hole “C” of the LOADING RACK should be aligned with the reference hole of the R LOADING Ass’y to make the teeth of the LOADING RACK is aligned as shown in Fig. 4.4.

FIg. 4.4 Assembly reference between the LOADING RACK |

and the LOADING LEVER ASS’Y |

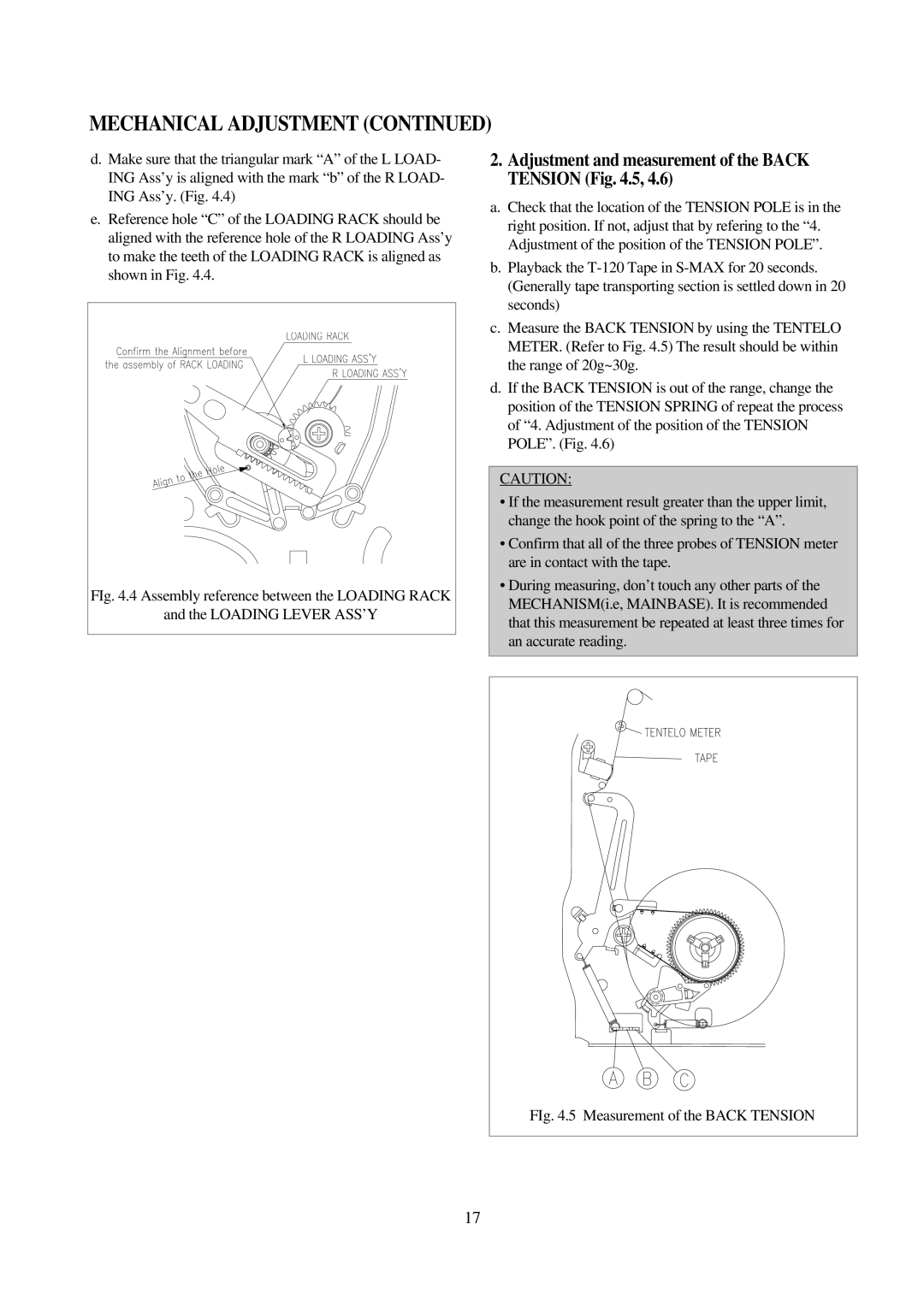

2.Adjustment and measurement of the BACK TENSION (Fig. 4.5, 4.6)

a.Check that the location of the TENSION POLE is in the right position. If not, adjust that by refering to the “4. Adjustment of the position of the TENSION POLE”.

b.Playback the

c.Measure the BACK TENSION by using the TENTELO METER. (Refer to Fig. 4.5) The result should be within the range of 20g~30g.

d.If the BACK TENSION is out of the range, change the position of the TENSION SPRING of repeat the process of “4. Adjustment of the position of the TENSION POLE”. (Fig. 4.6)

CAUTION:

•If the measurement result greater than the upper limit, change the hook point of the spring to the “A”.

•Confirm that all of the three probes of TENSION meter are in contact with the tape.

•During measuring, don’t touch any other parts of the MECHANISM(i.e, MAINBASE). It is recommended that this measurement be repeated at least three times for an accurate reading.

FIg. 4.5 Measurement of the BACK TENSION |

17