5.Depending on the type of saw blade being used, the cursor (D) Fig. 64, may need adjustment to compensate for the blade thickness.To adjust the cursor, make a test cut on a piece of lumber and measure the finished cut, or you can place the rip fence against the blade as shown earlier in the manual. If a minor adjustment is necessary, loosen two screws (E) Fig. 64, and move the cursor (D) as necessary.

MITER GAGE OPERATION AND ADJUSTMENT

Insert the miter gage bar (B) Fig. 65, into the miter gage slot. Insert the metal stud on the bottom of the miter gage body (C) Fig. 65, into the non tapped hole in the miter gage bar. Place a 21/64" flat washer (D) Fig. 65, onto the miter gage handle (A). Insert the threaded end of the miter gage handle (A) Fig. 65 through the slot (E) on the miter gage body and thread the handle into the miter gage bar (B).

The miter gage is equipped with adjustable index stops at 90 degrees and 45 degrees right and left. The index stops can be adjusted by tightening or loosening the three adjusting screws (B) Fig. 66.

To rotate the miter gage, loosen lock knob (A) Fig. 66, and move the body of the miter gage (C) to the desired angle.

The miter gage body will stop at 90 degrees and 45 degrees both right and left. To rotate the miter gage body past these points, lift the stop link (D) Fig. 66, up and out of the way.

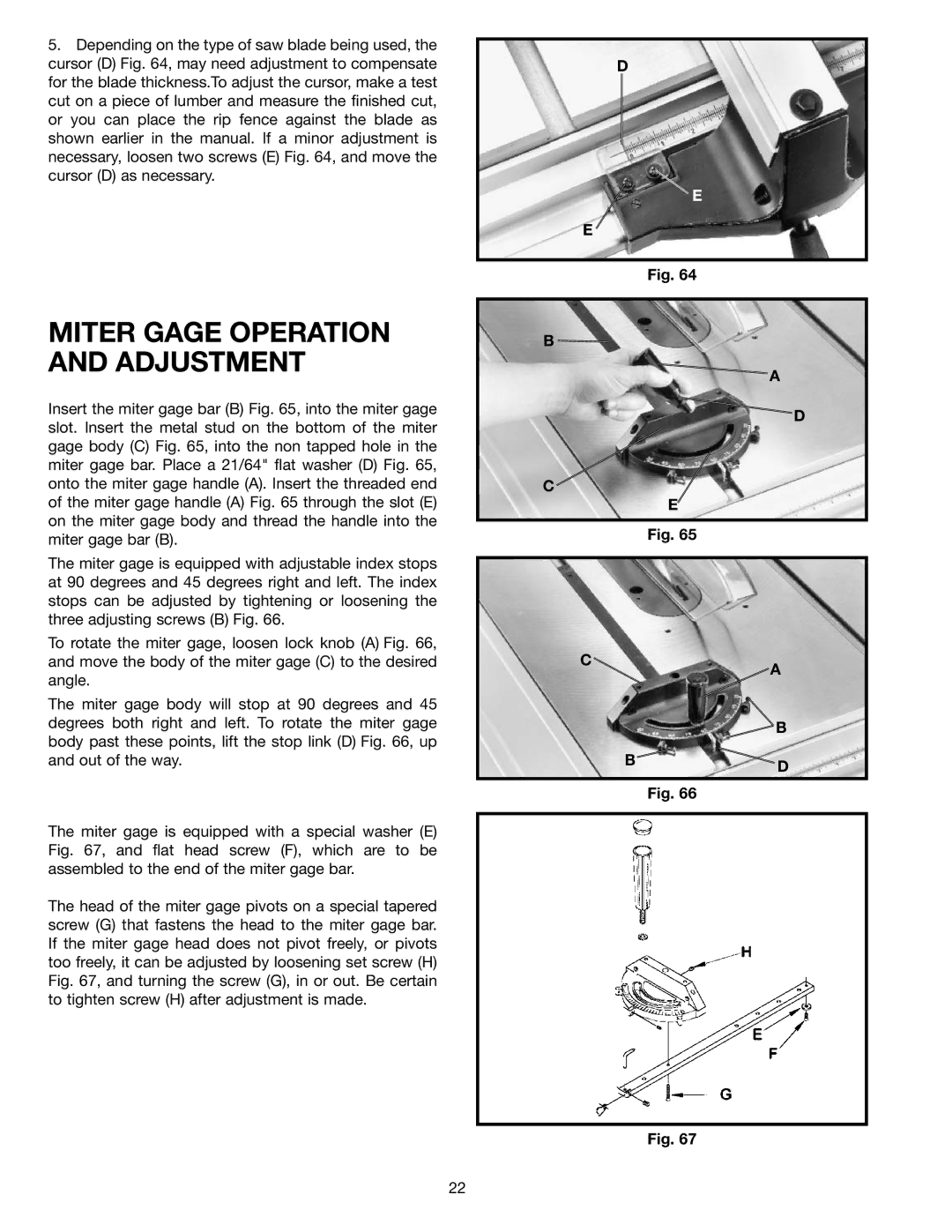

The miter gage is equipped with a special washer (E) Fig. 67, and flat head screw (F), which are to be assembled to the end of the miter gage bar.

The head of the miter gage pivots on a special tapered screw (G) that fastens the head to the miter gage bar. If the miter gage head does not pivot freely, or pivots too freely, it can be adjusted by loosening set screw (H) Fig. 67, and turning the screw (G), in or out. Be certain to tighten screw (H) after adjustment is made.

D

E

E

Fig. 64

B ![]()

A

D

C

E

Fig. 65

C

![]() A

A

![]() B

B

B![]() D

D

Fig. 66

Fig. 67

22