ADJUSTING TABLE INSERT

DISCONNECT MACHINE FROM POWER

SOURCE.

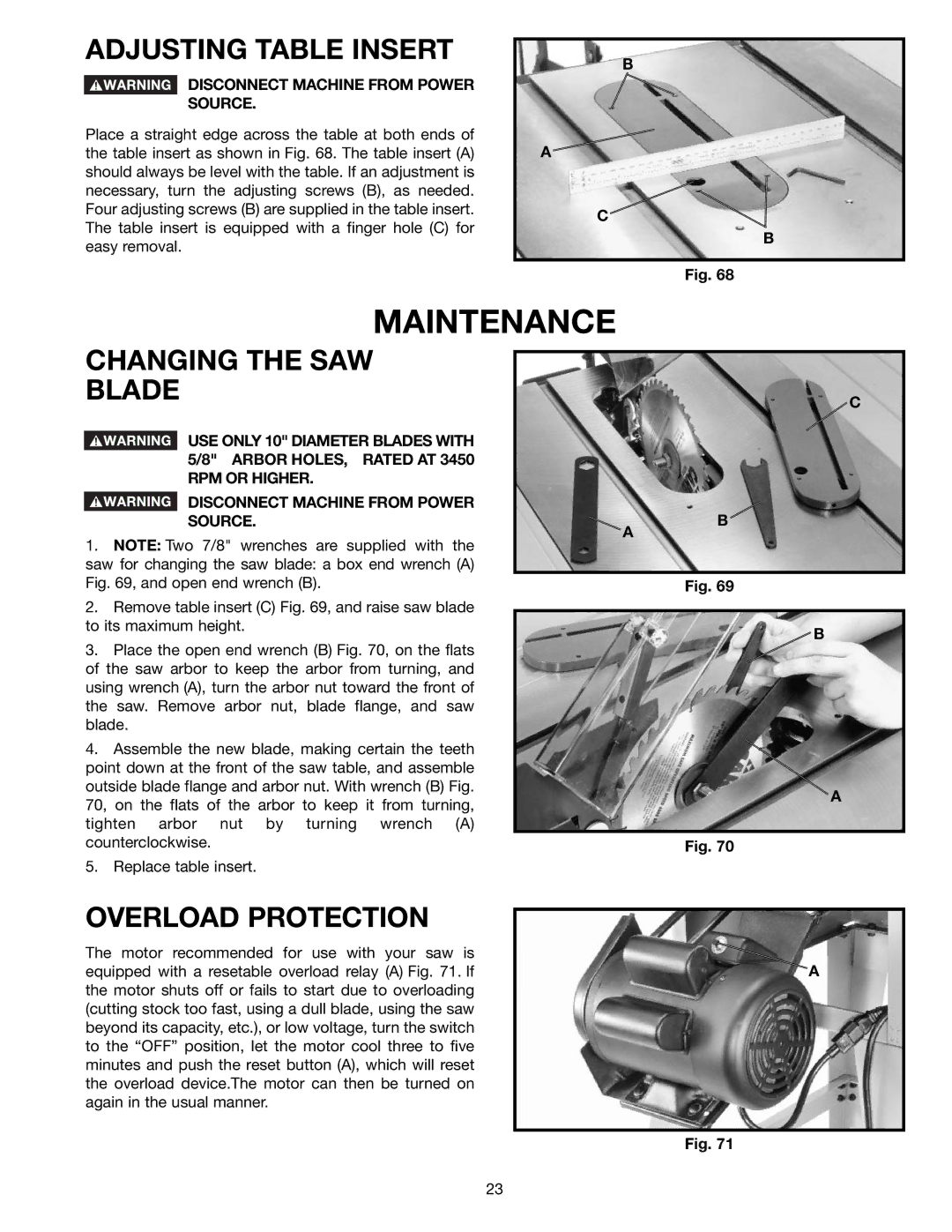

Place a straight edge across the table at both ends of the table insert as shown in Fig. 68. The table insert (A) should always be level with the table. If an adjustment is necessary, turn the adjusting screws (B), as needed. Four adjusting screws (B) are supplied in the table insert. The table insert is equipped with a finger hole (C) for easy removal.

B

A

C

B

Fig. 68

MAINTENANCE

CHANGING THE SAW

BLADE

USE ONLY 10" DIAMETER BLADES WITH 5/8" ARBOR HOLES, RATED AT 3450 RPM OR HIGHER.

DISCONNECT MACHINE FROM POWER

SOURCE.

1.NOTE: Two 7/8" wrenches are supplied with the saw for changing the saw blade: a box end wrench (A) Fig. 69, and open end wrench (B).

2.Remove table insert (C) Fig. 69, and raise saw blade to its maximum height.

3.Place the open end wrench (B) Fig. 70, on the flats of the saw arbor to keep the arbor from turning, and using wrench (A), turn the arbor nut toward the front of the saw. Remove arbor nut, blade flange, and saw blade.

4.Assemble the new blade, making certain the teeth point down at the front of the saw table, and assemble outside blade flange and arbor nut. With wrench (B) Fig. 70, on the flats of the arbor to keep it from turning, tighten arbor nut by turning wrench (A) counterclockwise.

5.Replace table insert.

![]() C

C

B

A

Fig. 69

![]() B

B

A

Fig. 70

OVERLOAD PROTECTION

The motor recommended for use with your saw is equipped with a resetable overload relay (A) Fig. 71. If the motor shuts off or fails to start due to overloading (cutting stock too fast, using a dull blade, using the saw beyond its capacity, etc.), or low voltage, turn the switch to the “OFF” position, let the motor cool three to five minutes and push the reset button (A), which will reset the overload device.The motor can then be turned on again in the usual manner.

A

Fig. 71

23