USING AUXILIARY WOOD FACING ON RIP FENCE

![]() It is necessary when performing special operations such as moulding to add wood facing (A) Fig. 94, to one or both sides of the rip fence, as shown. The wood facing is attached to the fence with wood screws (B), countersunk and assembled through the holes provided in the fence. 3/4 inch stock is suitable for most work although an occasional job may require 1 inch facing.

It is necessary when performing special operations such as moulding to add wood facing (A) Fig. 94, to one or both sides of the rip fence, as shown. The wood facing is attached to the fence with wood screws (B), countersunk and assembled through the holes provided in the fence. 3/4 inch stock is suitable for most work although an occasional job may require 1 inch facing.

![]() A wood facing should be used when ripping thin material such as paneling to prevent the material from catching between the bottom of the rip fence and the saw table surface.

A wood facing should be used when ripping thin material such as paneling to prevent the material from catching between the bottom of the rip fence and the saw table surface.

B![]()

![]() A

A

B

Fig. 94

CONSTRUCTING A FEATHERBOARD

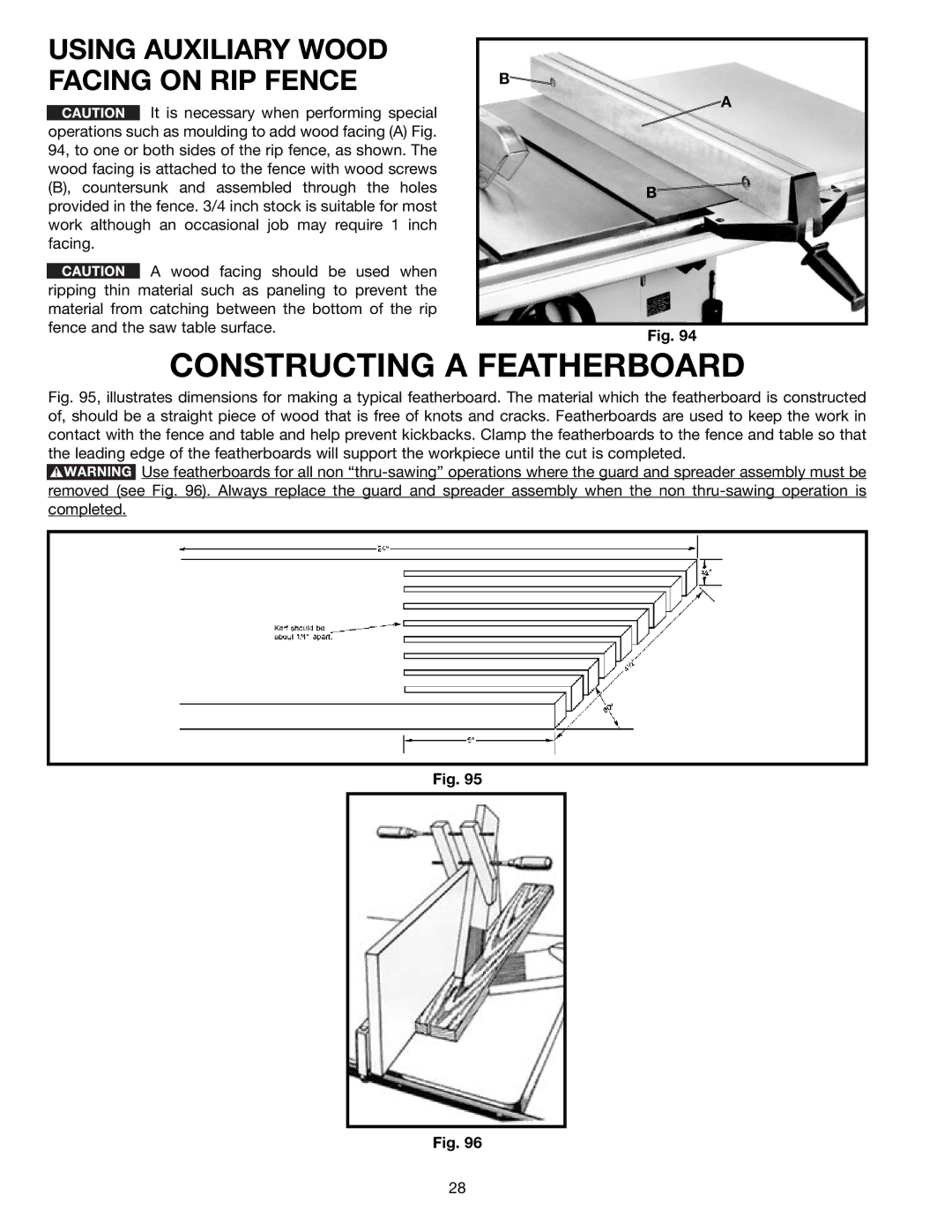

Fig. 95, illustrates dimensions for making a typical featherboard. The material which the featherboard is constructed of, should be a straight piece of wood that is free of knots and cracks. Featherboards are used to keep the work in contact with the fence and table and help prevent kickbacks. Clamp the featherboards to the fence and table so that the leading edge of the featherboards will support the workpiece until the cut is completed.

Use featherboards for all non

Use featherboards for all non “thru-sawing” operations where the guard and spreader assembly must be removed (see Fig. 96). Always replace the guard and spreader assembly when the non thru-sawing operation is completed.

Fig. 95

Fig. 96

28