![]() HAZARDOUS RADIATION. Use or modi- fication of the tool for anything other than its designed purpose may result in hazardous radiation exposure.

HAZARDOUS RADIATION. Use or modi- fication of the tool for anything other than its designed purpose may result in hazardous radiation exposure.

• The label on your tool may include the following symbols.

V | volts | mW | milliwatts | ||

| ..... Laser warning | nm | wavelength in | ||

| symbol |

| ............. | nanometers | |

II | Class II Laser | IIIa | Class IIIa Laser | ||

| alternating current |

|

|

| direct current |

.............. |

|

| ...... | ||

|

|

|

| ||

W | watts | Hz | hertz | ||

WARNING LABELS

For your convenience and safety, the following label is on your laser:

LASER SPECIFICATIONS

LIGHT SOURCE | Dual semiconductor laser diode |

|

|

LASER WAVELENGTH | 630nm – 680nm Visible |

|

|

LASER POWER | <1mw (each beam) CLASS II |

| LASER PRODUCT |

|

|

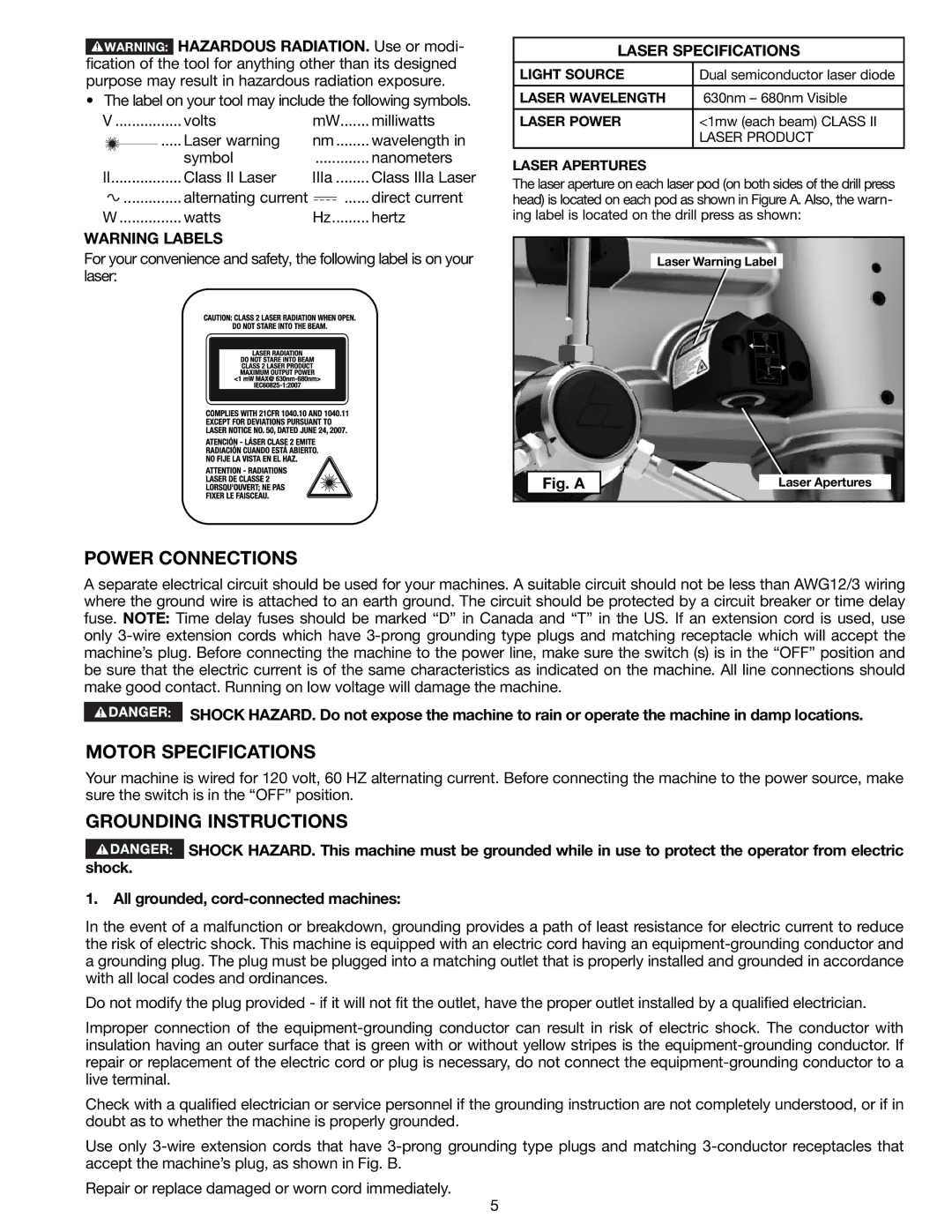

LASER APERTURES

The laser aperture on each laser pod (on both sides of the drill press head) is located on each pod as shown in Figure A. Also, the warn- ing label is located on the drill press as shown:

Laser Warning Label

Fig. A | Laser Apertures |

POWER CONNECTIONS

A separate electrical circuit should be used for your machines. A suitable circuit should not be less than AWG12/3 wiring where the ground wire is attached to an earth ground. The circuit should be protected by a circuit breaker or time delay fuse. NOTE: Time delay fuses should be marked “D” in Canada and “T” in the US. If an extension cord is used, use only

![]() SHOCK HAZARD. Do not expose the machine to rain or operate the machine in damp locations.

SHOCK HAZARD. Do not expose the machine to rain or operate the machine in damp locations.

MOTOR SPECIFICATIONS

Your machine is wired for 120 volt, 60 HZ alternating current. Before connecting the machine to the power source, make sure the switch is in the “OFF” position.

GROUNDING INSTRUCTIONS

![]() SHOCK HAZARD. This machine must be grounded while in use to protect the operator from electric shock.

SHOCK HAZARD. This machine must be grounded while in use to protect the operator from electric shock.

1. All grounded,

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This machine is equipped with an electric cord having an

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the

Check with a qualified electrician or service personnel if the grounding instruction are not completely understood, or if in doubt as to whether the machine is properly grounded.

Use only

Repair or replace damaged or worn cord immediately.

5