RAISING AND LOWERING THE SPINDLE

![]() To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental

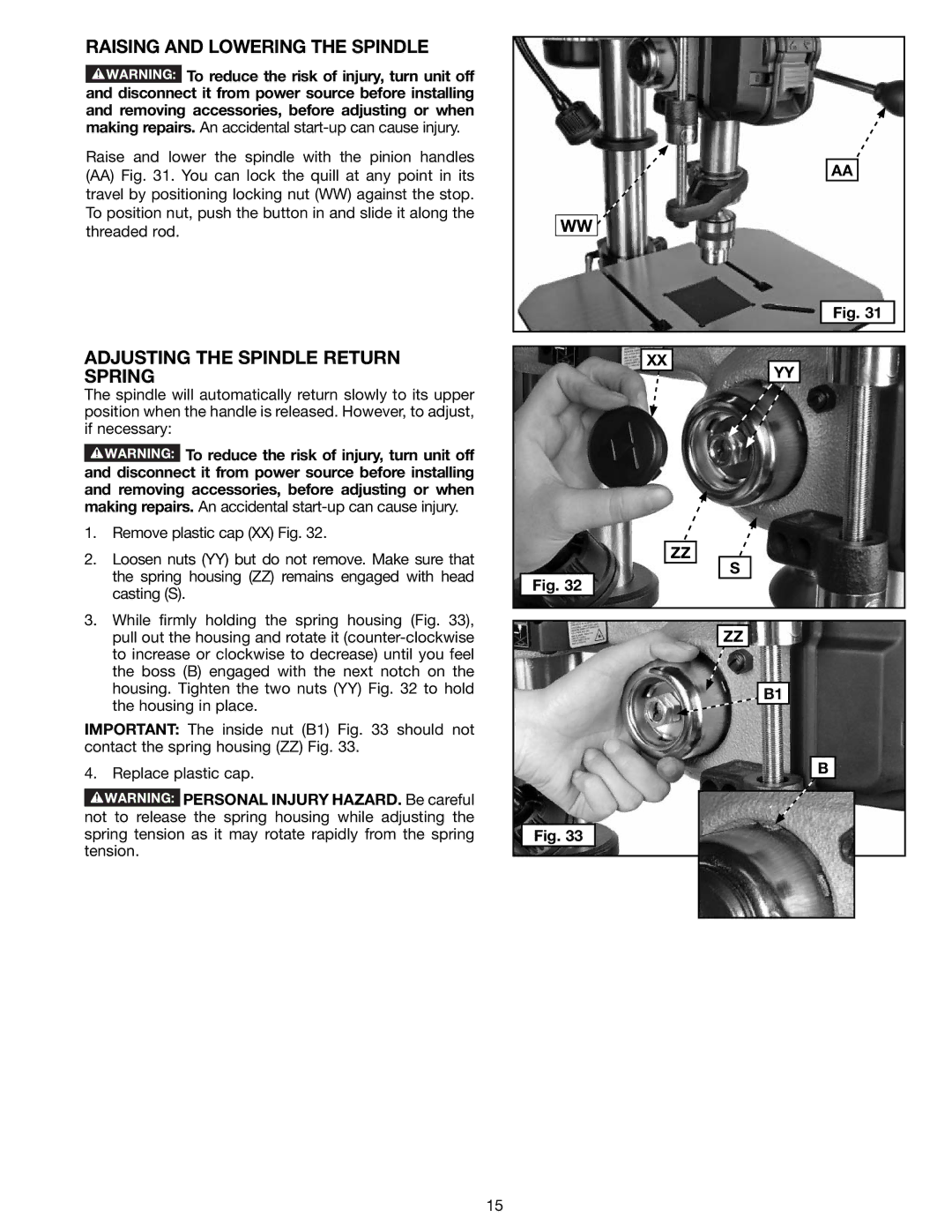

Raise and lower the spindle with the pinion handles

(AA)Fig. 31. You can lock the quill at any point in its travel by positioning locking nut (WW) against the stop. To position nut, push the button in and slide it along the threaded rod.

ADJUSTING THE SPINDLE RETURN SPRING

The spindle will automatically return slowly to its upper position when the handle is released. However, to adjust, if necessary:

![]() To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental

1.Remove plastic cap (XX) Fig. 32.

2.Loosen nuts (YY) but do not remove. Make sure that the spring housing (ZZ) remains engaged with head casting (S).

3.While firmly holding the spring housing (Fig. 33), pull out the housing and rotate it

IMPORTANT: The inside nut (B1) Fig. 33 should not contact the spring housing (ZZ) Fig. 33.

4. Replace plastic cap.

![]() PERSONAL INJURY HAZARD. Be careful not to release the spring housing while adjusting the spring tension as it may rotate rapidly from the spring tension.

PERSONAL INJURY HAZARD. Be careful not to release the spring housing while adjusting the spring tension as it may rotate rapidly from the spring tension.

AA

WW

Fig. 31

XX

YY

ZZ![]()

![]()

S

Fig. 32

ZZ

B1

B

Fig. 33

15