E

G

![]() F

F

F ![]()

B

Fig. 3

ASSEMBLING DRILL PRESS PARTS

|

| Fig. 4 |

I |

| |

|

|

J

H

![]() RISK OF UNSAFE OPERATION. If your drill press is not permanently fastened to the floor it may be mounted to a plywood board to improve stability and prevent tipping.

RISK OF UNSAFE OPERATION. If your drill press is not permanently fastened to the floor it may be mounted to a plywood board to improve stability and prevent tipping.

![]() To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental

L

Fig. 5

K

Q

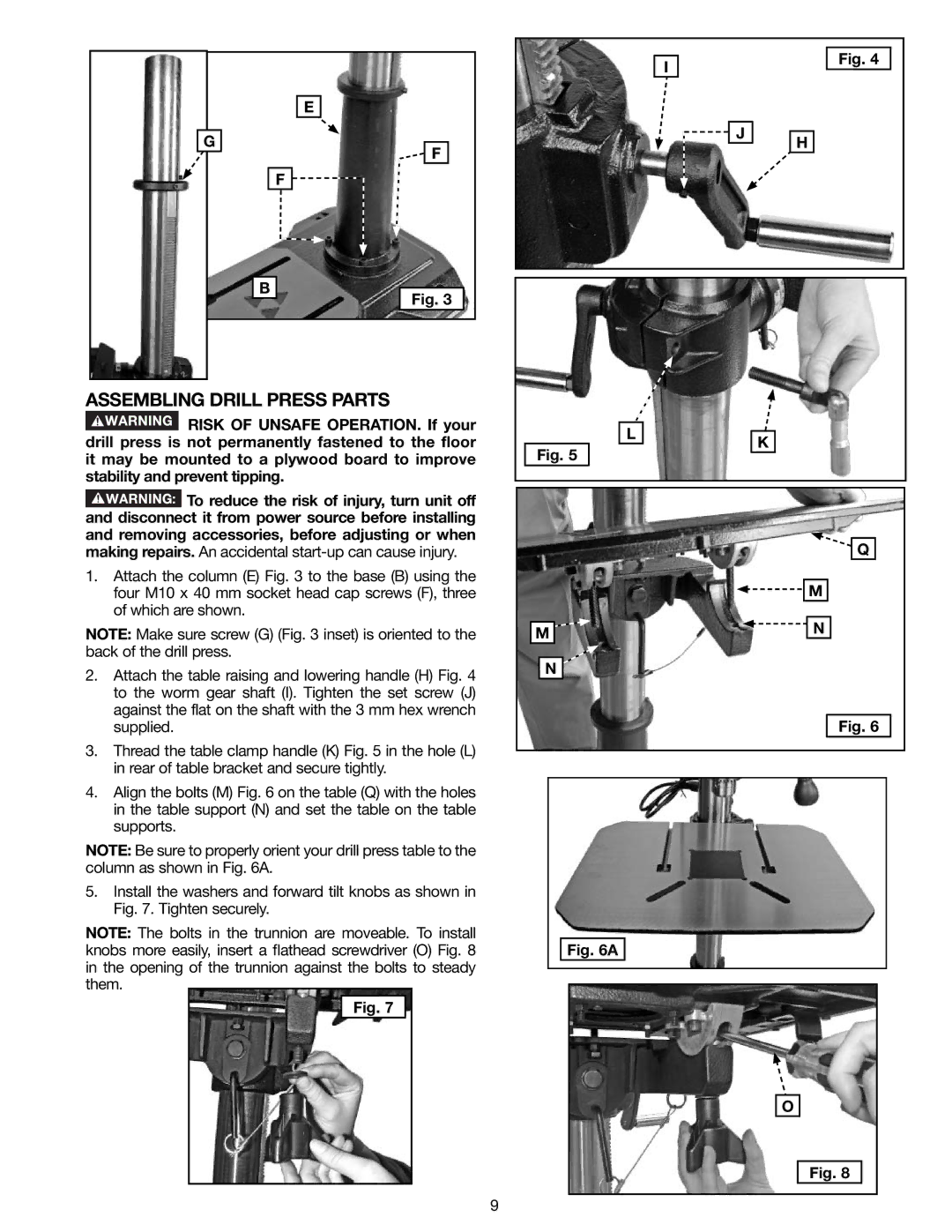

1.Attach the column (E) Fig. 3 to the base (B) using the four M10 x 40 mm socket head cap screws (F), three of which are shown.

NOTE: Make sure screw (G) (Fig. 3 inset) is oriented to the back of the drill press.

2.Attach the table raising and lowering handle (H) Fig. 4 to the worm gear shaft (I). Tighten the set screw (J) against the flat on the shaft with the 3 mm hex wrench supplied.

3.Thread the table clamp handle (K) Fig. 5 in the hole (L) in rear of table bracket and secure tightly.

4.Align the bolts (M) Fig. 6 on the table (Q) with the holes in the table support (N) and set the table on the table supports.

NOTE: Be sure to properly orient your drill press table to the column as shown in Fig. 6A.

5.Install the washers and forward tilt knobs as shown in Fig. 7. Tighten securely.

NOTE: The bolts in the trunnion are moveable. To install knobs more easily, insert a flathead screwdriver (O) Fig. 8 in the opening of the trunnion against the bolts to steady them.

Fig. 7

9

| M |

M | N |

| |

N |

|

Fig. 6

Fig. 6A

O

Fig. 8