ASSEMBLY

![]() To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental

ASSEMBLY TOOLS REQUIRED | ASSEMBLY TIME ESTIMATE |

Hex wrenches (supplied) Rubber mallet (not supplied) 10mm wrench

Assembly for this machine takes approximately 30 minutes to 1 hour.

ATTACHING DRILL PRESS

TO SUPPORTING SURFACE

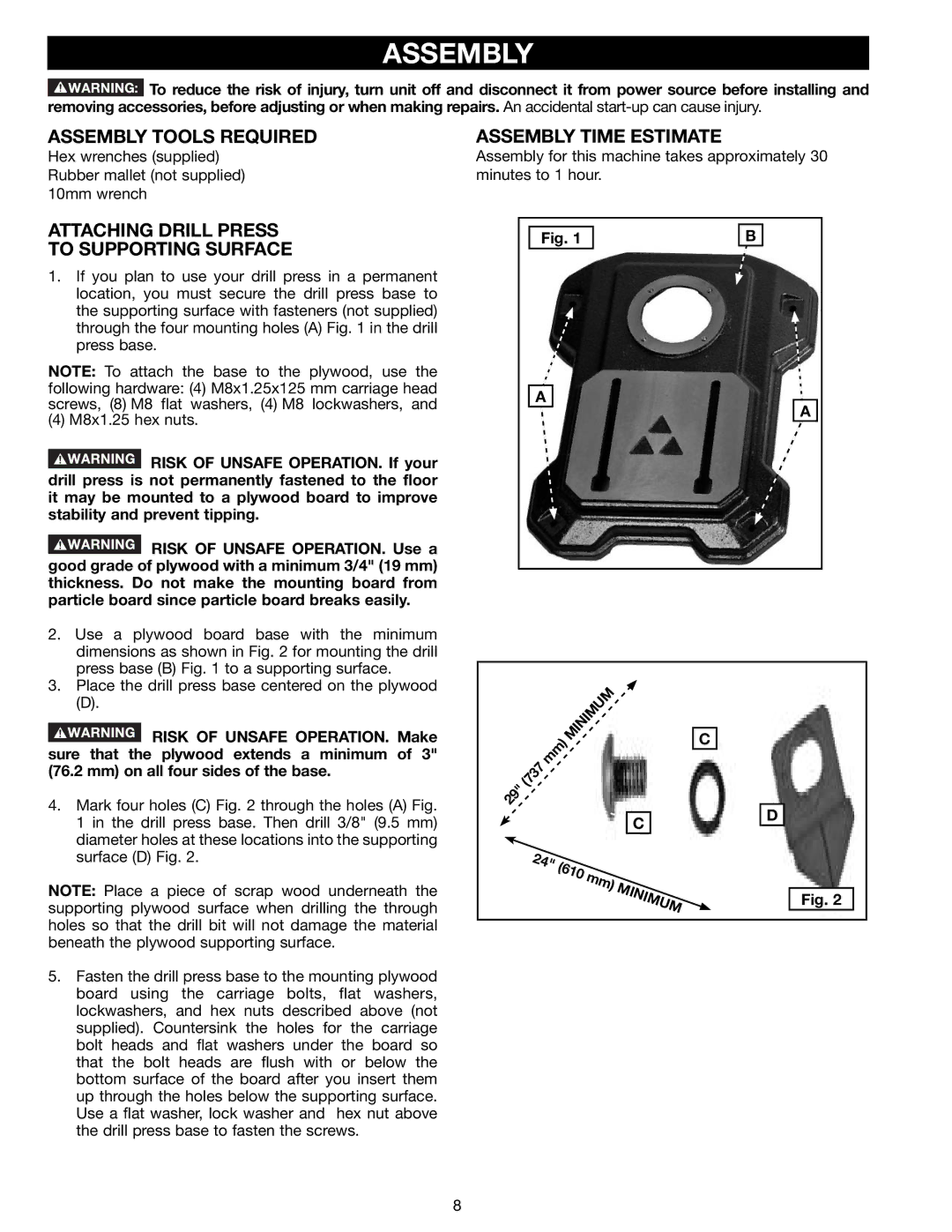

1.If you plan to use your drill press in a permanent location, you must secure the drill press base to the supporting surface with fasteners (not supplied) through the four mounting holes (A) Fig. 1 in the drill press base.

NOTE: To attach the base to the plywood, use the

following hardware: (4) M8x1.25x125 mm carriage head screws, (8) M8 flat washers, (4) M8 lockwashers, and

(4) M8x1.25 hex nuts.

![]() RISK OF UNSAFE OPERATION. If your drill press is not permanently fastened to the floor it may be mounted to a plywood board to improve stability and prevent tipping.

RISK OF UNSAFE OPERATION. If your drill press is not permanently fastened to the floor it may be mounted to a plywood board to improve stability and prevent tipping.

![]() RISK OF UNSAFE OPERATION. Use a good grade of plywood with a minimum 3/4" (19 mm) thickness. Do not make the mounting board from particle board since particle board breaks easily.

RISK OF UNSAFE OPERATION. Use a good grade of plywood with a minimum 3/4" (19 mm) thickness. Do not make the mounting board from particle board since particle board breaks easily.

2.Use a plywood board base with the minimum dimensions as shown in Fig. 2 for mounting the drill press base (B) Fig. 1 to a supporting surface.

3.Place the drill press base centered on the plywood

(D).

![]() RISK OF UNSAFE OPERATION. Make sure that the plywood extends a minimum of 3" (76.2 mm) on all four sides of the base.

RISK OF UNSAFE OPERATION. Make sure that the plywood extends a minimum of 3" (76.2 mm) on all four sides of the base.

4.Mark four holes (C) Fig. 2 through the holes (A) Fig. 1 in the drill press base. Then drill 3/8" (9.5 mm) diameter holes at these locations into the supporting surface (D) Fig. 2.

NOTE: Place a piece of scrap wood underneath the supporting plywood surface when drilling the through holes so that the drill bit will not damage the material beneath the plywood supporting surface.

5.Fasten the drill press base to the mounting plywood board using the carriage bolts, flat washers, lockwashers, and hex nuts described above (not supplied). Countersink the holes for the carriage bolt heads and flat washers under the board so that the bolt heads are flush with or below the bottom surface of the board after you insert them up through the holes below the supporting surface. Use a flat washer, lock washer and hex nut above the drill press base to fasten the screws.

Fig. 1 | B |

A

A

|

| mm) | MINIMUM |

| C | ||

| (737 |

|

|

|

| ||

29" |

|

|

|

|

|

| |

|

|

|

|

|

| D | |

|

|

|

|

|

| C | |

|

|

|

|

|

|

| |

| 24" | (610 | mm) |

|

| ||

|

|

| MINIMUM |

| |||

|

|

|

|

| Fig. 2 | ||

|

|

|

|

|

| ||

|

|

|

|

|

|

| |

8