SURFACING WARPED PIECES

If the wood to be surfaced is dished or warped, take light cuts until the surface is flat. Avoid forcing such material down against the table; excessive pressure will spring it while passing the knives, and it will spring back and remain curved after the cut is completed.

SURFACING SHORT

OR THIN WORK

![]() WHEN SURFACING SHORT OR THIN PIECES, ALWAYS USE PUSH BLOCKS TO MINIMIZE ALL DANGER TO THE HANDS. Fig. 67, illustrates using the Delta Push Blocks properly.

WHEN SURFACING SHORT OR THIN PIECES, ALWAYS USE PUSH BLOCKS TO MINIMIZE ALL DANGER TO THE HANDS. Fig. 67, illustrates using the Delta Push Blocks properly.

![]() DO NOT PERFORM SURFACING OPERATIONS ON MATERIAL SHORTER THAN 10 INCHES, NARROWER THAN 3/4 INCH, WIDER THAN 8 INCHES, OR LESS THAN 1/2 INCH THICK (REFER TO FIG. 68).

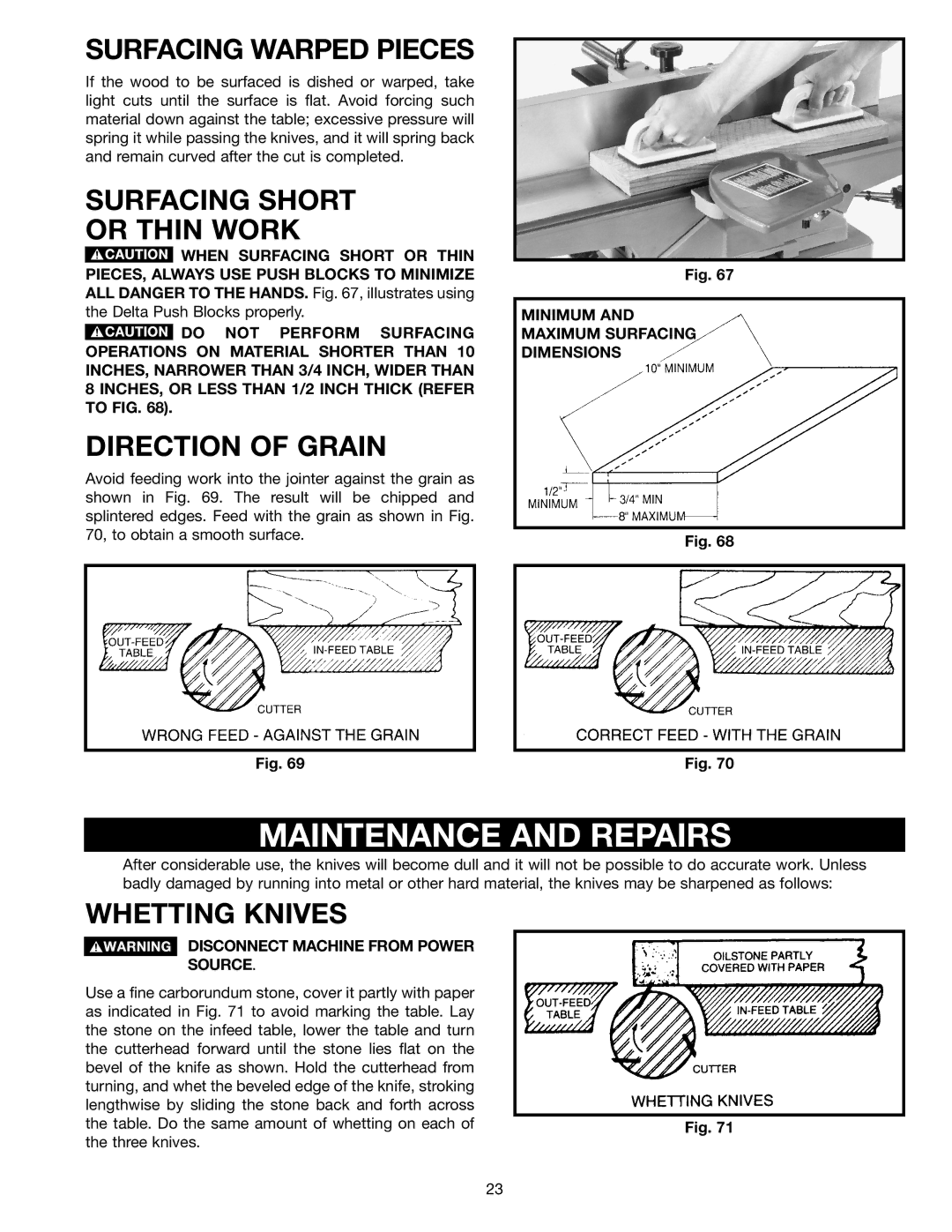

DO NOT PERFORM SURFACING OPERATIONS ON MATERIAL SHORTER THAN 10 INCHES, NARROWER THAN 3/4 INCH, WIDER THAN 8 INCHES, OR LESS THAN 1/2 INCH THICK (REFER TO FIG. 68).

DIRECTION OF GRAIN

Avoid feeding work into the jointer against the grain as shown in Fig. 69. The result will be chipped and splintered edges. Feed with the grain as shown in Fig. 70, to obtain a smooth surface.

Fig. 69

Fig. 67

MINIMUM AND MAXIMUM SURFACING DIMENSIONS

Fig. 68

Fig. 70

MAINTENANCE AND REPAIRS

After considerable use, the knives will become dull and it will not be possible to do accurate work. Unless badly damaged by running into metal or other hard material, the knives may be sharpened as follows:

WHETTING KNIVES

DISCONNECT MACHINE FROM POWER

SOURCE.

Use a fine carborundum stone, cover it partly with paper as indicated in Fig. 71 to avoid marking the table. Lay the stone on the infeed table, lower the table and turn the cutterhead forward until the stone lies flat on the bevel of the knife as shown. Hold the cutterhead from turning, and whet the beveled edge of the knife, stroking lengthwise by sliding the stone back and forth across

the table. Do the same amount of whetting on each ofFig. 71 the three knives.

23