2.Raise or lower the infeed table adjustment lever (C) Fig. 35.

3.IMPORTANT: When lowering the infeed table, a depth stop (D) Fig. 35, will automatically stop the table at a 1/8"

4.The

INFEED TABLE

POSITIVE STOPS

D I S C O N N E C T M A C H I N E F R O M

POWER SOURCE.

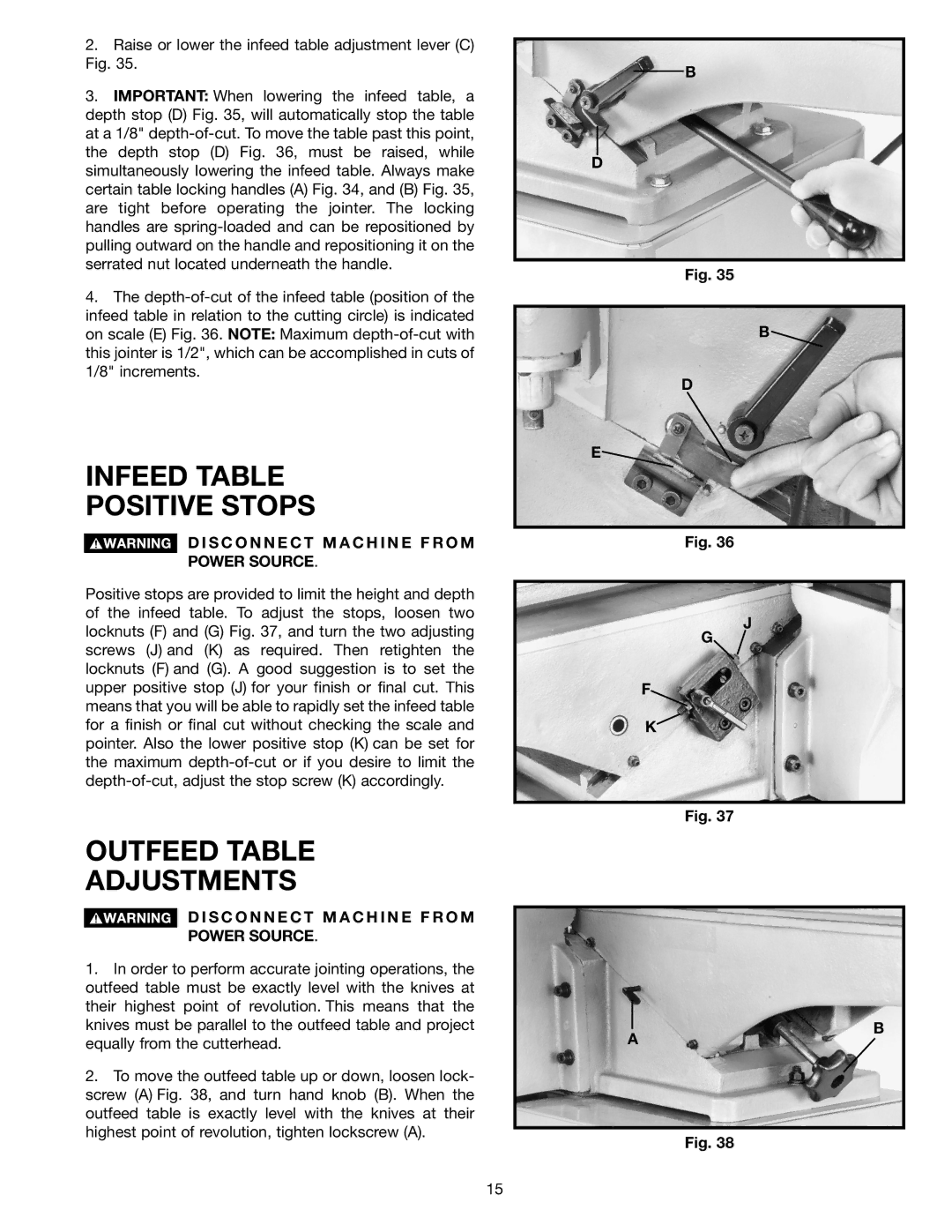

Positive stops are provided to limit the height and depth of the infeed table. To adjust the stops, loosen two locknuts (F) and (G) Fig. 37, and turn the two adjusting screws (J) and (K) as required. Then retighten the locknuts (F) and (G). A good suggestion is to set the upper positive stop (J) for your finish or final cut. This means that you will be able to rapidly set the infeed table for a finish or final cut without checking the scale and pointer. Also the lower positive stop (K) can be set for the maximum

OUTFEED TABLE

ADJUSTMENTS

D I S C O N N E C T M A C H I N E F R O M

POWER SOURCE.

B

D

Fig. 35

B![]()

D

E![]()

Fig. 36

J

G

F

K

Fig. 37

1. | In order to perform accurate jointing operations, the |

outfeed table must be exactly level with the knives at | |

their highest point of revolution. This means that the | |

knives must be parallel to the outfeed table and project | |

equally from the cutterhead. | |

2. | To move the outfeed table up or down, loosen lock- |

screw (A) Fig. 38, and turn hand knob (B). When the | |

outfeed table is exactly level with the knives at their | |

highest point of revolution, tighten lockscrew (A). | |

A

B

Fig. 38

15