EDGE 540. | Instruction Manual. |

|

|

4)A drop of C/A glue on the wheel collar screws will help keep them from coming lose during operation.

Repeat the process for the other wheel.

INSTALLING THE MAIN LANDING

GEAR.

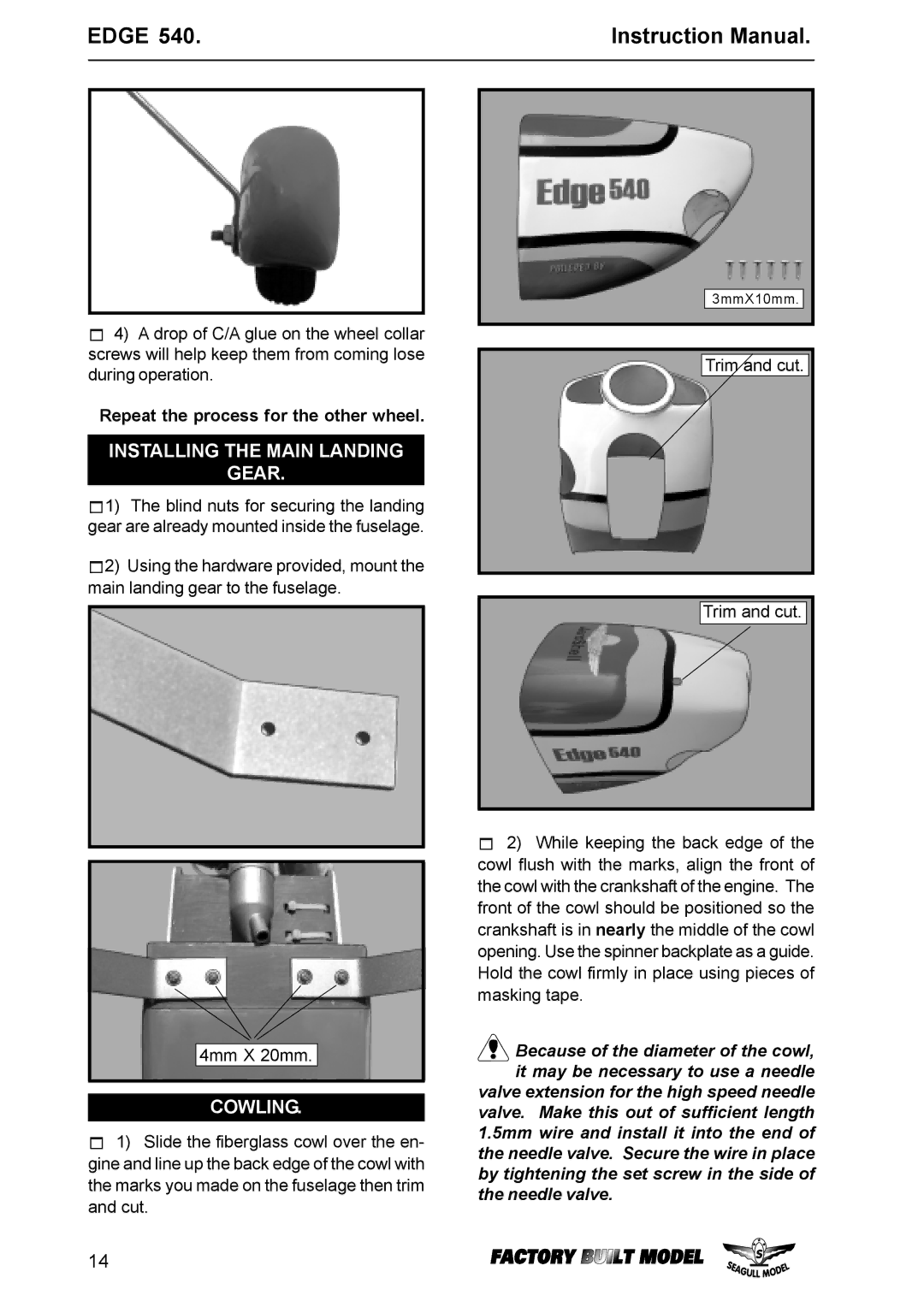

1)The blind nuts for securing the landing gear are already mounted inside the fuselage.

2)Using the hardware provided, mount the main landing gear to the fuselage.

4mm X 20mm.

COWLING.

1)Slide the fiberglass cowl over the en- gine and line up the back edge of the cowl with the marks you made on the fuselage then trim and cut.

14

3mmX10mm.

Trim and cut.

Trim and cut.

2)While keeping the back edge of the cowl flush with the marks, align the front of the cowl with the crankshaft of the engine. The front of the cowl should be positioned so the crankshaft is in nearly the middle of the cowl opening. Use the spinner backplate as a guide. Hold the cowl firmly in place using pieces of masking tape.

![]()

![]() Because of the diameter of the cowl, it may be necessary to use a needle valve extension for the high speed needle valve. Make this out of sufficient length 1.5mm wire and install it into the end of the needle valve. Secure the wire in place by tightening the set screw in the side of

Because of the diameter of the cowl, it may be necessary to use a needle valve extension for the high speed needle valve. Make this out of sufficient length 1.5mm wire and install it into the end of the needle valve. Secure the wire in place by tightening the set screw in the side of

the needle valve.