|

| SW375 RECEIVER | |

|

| TO | |

|

| 120V SUPPLY | |

|

| SW350 | |

YELLOW WIRE | WALL CONTROL OR | ||

TO YELLOW | ON/OFF WALL SWITCH | ||

WIRE |

| BLACK WIRE | |

BLUE WIRE TO | |||

RECEIVER | |||

BLUE WIRE | CONNECTOR | ||

|

| WIRING HARNESS | |

|

| CONNECTOR | |

|

| WHITE WIRE | |

| RED WIRE | HANGER | |

| PIPE | ||

YELLOW WIRE | (FROM THE |

| |

MOTOR) TO |

| ||

(FROM THE | RED WIRE | WHITE WIRE TO | |

MOTOR) TO |

| ||

YELLOW WIRE |

| WHITE WIRE | |

BROWN WIRE |

|

| |

(FROM THE MOTOR) |

| BLUE WIRE TO | |

TO BROWN WIRE |

| ||

| BLUE WIRE | ||

RED WIRE (FROM THE |

| ||

| BLACK WIRE (NOT USED) | ||

REVERSING SWITCH) |

| ||

|

| ||

(NOT USED) |

|

| |

BROWN WIRE (FROM |

|

| |

THE REVERSING |

|

| |

SWITCH) (NOT USED) |

| FAN HOUSING AND | |

Figure 6A |

| SHADE ASSEMBLY | |

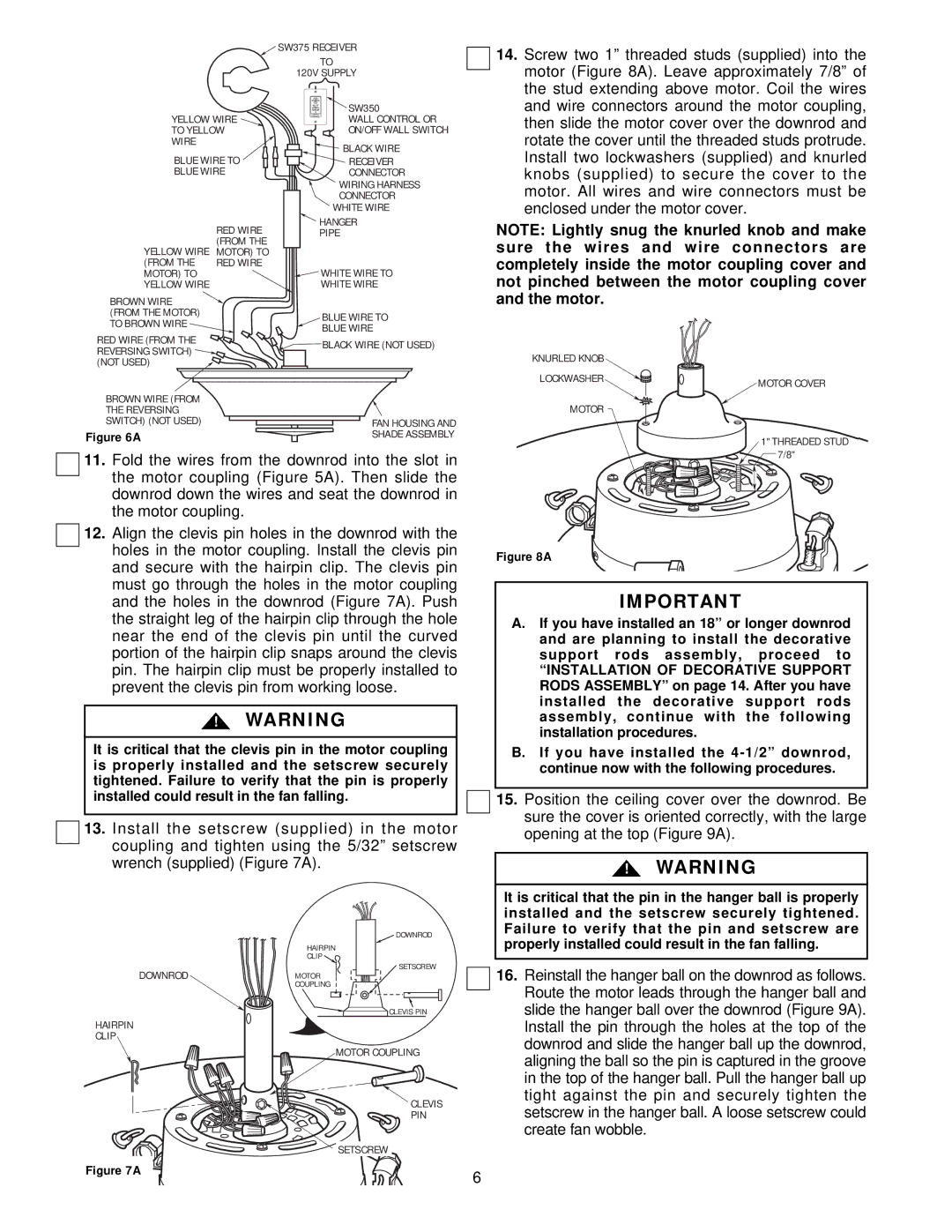

11.Fold the wires from the downrod into the slot in the motor coupling (Figure 5A). Then slide the downrod down the wires and seat the downrod in the motor coupling.

12.Align the clevis pin holes in the downrod with the holes in the motor coupling. Install the clevis pin and secure with the hairpin clip. The clevis pin must go through the holes in the motor coupling and the holes in the downrod (Figure 7A). Push the straight leg of the hairpin clip through the hole near the end of the clevis pin until the curved portion of the hairpin clip snaps around the clevis pin. The hairpin clip must be properly installed to prevent the clevis pin from working loose.

!WARNING

It is critical that the clevis pin in the motor coupling is properly installed and the setscrew securely tightened. Failure to verify that the pin is properly installed could result in the fan falling.

13.Install the setscrew (supplied) in the motor coupling and tighten using the 5/32” setscrew wrench (supplied) (Figure 7A).

| DOWNROD |

| HAIRPIN |

| CLIP |

DOWNROD | SETSCREW |

MOTOR | |

| COUPLING |

| CLEVIS PIN |

HAIRPIN |

|

CLIP |

|

| MOTOR COUPLING |

| CLEVIS |

| PIN |

| SETSCREW |

Figure 7A | 6 |

|

14.Screw two 1” threaded studs (supplied) into the motor (Figure 8A). Leave approximately 7/8” of the stud extending above motor. Coil the wires and wire connectors around the motor coupling, then slide the motor cover over the downrod and rotate the cover until the threaded studs protrude. Install two lockwashers (supplied) and knurled knobs (supplied) to secure the cover to the motor. All wires and wire connectors must be enclosed under the motor cover.

NOTE: Lightly snug the knurled knob and make sure the wires and wire connectors are completely inside the motor coupling cover and not pinched between the motor coupling cover and the motor.

KNURLED KNOB |

|

LOCKWASHER | MOTOR COVER |

| |

MOTOR |

|

| 1" THREADED STUD |

| 7/8" |

Figure 8A

IMPORTANT

A.If you have installed an 18” or longer downrod and are planning to install the decorative support rods assembly, proceed to

“INSTALLATION OF DECORATIVE SUPPORT RODS ASSEMBLY” on page 14. After you have installed the decorative support rods assembly, continue with the following installation procedures.

B.If you have installed the

15.Position the ceiling cover over the downrod. Be sure the cover is oriented correctly, with the large opening at the top (Figure 9A).

!WARNING

It is critical that the pin in the hanger ball is properly installed and the setscrew securely tightened. Failure to verify that the pin and setscrew are properly installed could result in the fan falling.

16.Reinstall the hanger ball on the downrod as follows. Route the motor leads through the hanger ball and slide the hanger ball over the downrod (Figure 9A). Install the pin through the holes at the top of the downrod and slide the hanger ball up the downrod, aligning the ball so the pin is captured in the groove in the top of the hanger ball. Pull the hanger ball up tight against the pin and securely tighten the setscrew in the hanger ball. A loose setscrew could create fan wobble.