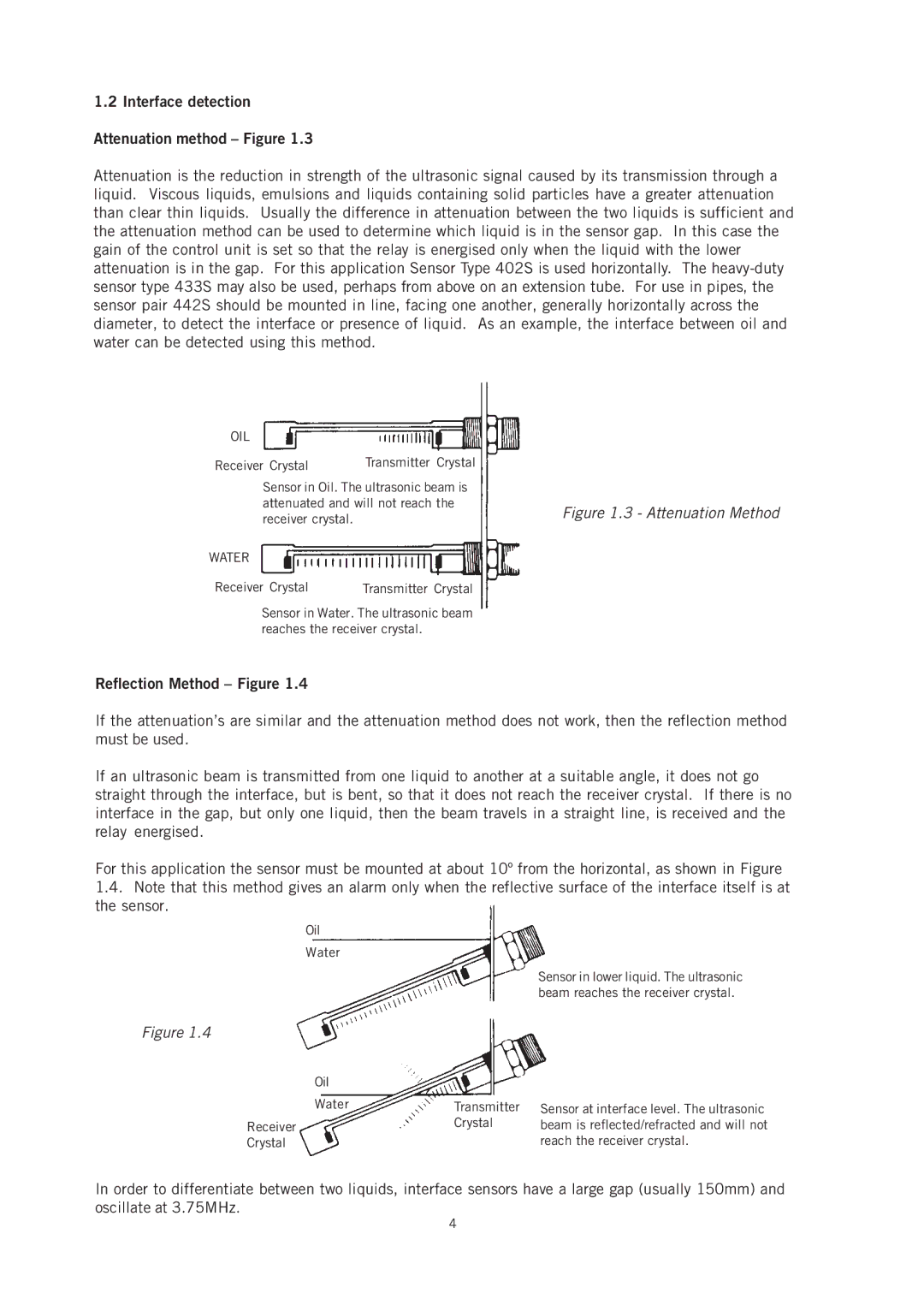

1.2Interface detection Attenuation method – Figure 1.3

Attenuation is the reduction in strength of the ultrasonic signal caused by its transmission through a liquid. Viscous liquids, emulsions and liquids containing solid particles have a greater attenuation than clear thin liquids. Usually the difference in attenuation between the two liquids is sufficient and the attenuation method can be used to determine which liquid is in the sensor gap. In this case the gain of the control unit is set so that the relay is energised only when the liquid with the lower attenuation is in the gap. For this application Sensor Type 402S is used horizontally. The

OIL |

|

Receiver Crystal | Transmitter Crystal |

Sensor in Oil. The ultrasonic beam is | |

attenuated and will not reach the | |

receiver crystal. | Figure 1.3 - Attenuation Method |

| |

WATER |

|

Receiver Crystal | Transmitter Crystal |

Sensor in Water. The ultrasonic beam reaches the receiver crystal.

Reflection Method – Figure 1.4

If the attenuation’s are similar and the attenuation method does not work, then the reflection method must be used.

If an ultrasonic beam is transmitted from one liquid to another at a suitable angle, it does not go straight through the interface, but is bent, so that it does not reach the receiver crystal. If there is no interface in the gap, but only one liquid, then the beam travels in a straight line, is received and the relay energised.

For this application the sensor must be mounted at about 10º from the horizontal, as shown in Figure

1.4.Note that this method gives an alarm only when the reflective surface of the interface itself is at the sensor.

Oil

Water

Sensor in lower liquid. The ultrasonic beam reaches the receiver crystal.

Figure 1.4

Oil

Water

Receiver

Crystal

Transmitter | Sensor at interface level. The ultrasonic |

Crystal | beam is reflected/refracted and will not |

| reach the receiver crystal. |

In order to differentiate between two liquids, interface sensors have a large gap (usually 150mm) and oscillate at 3.75MHz.

4