1.3 Solids Density Detection

The Electropulse system can be used in conjunction with a 433S type sensor to provide blanket level detection in settling tanks, facilitating the control of automatic

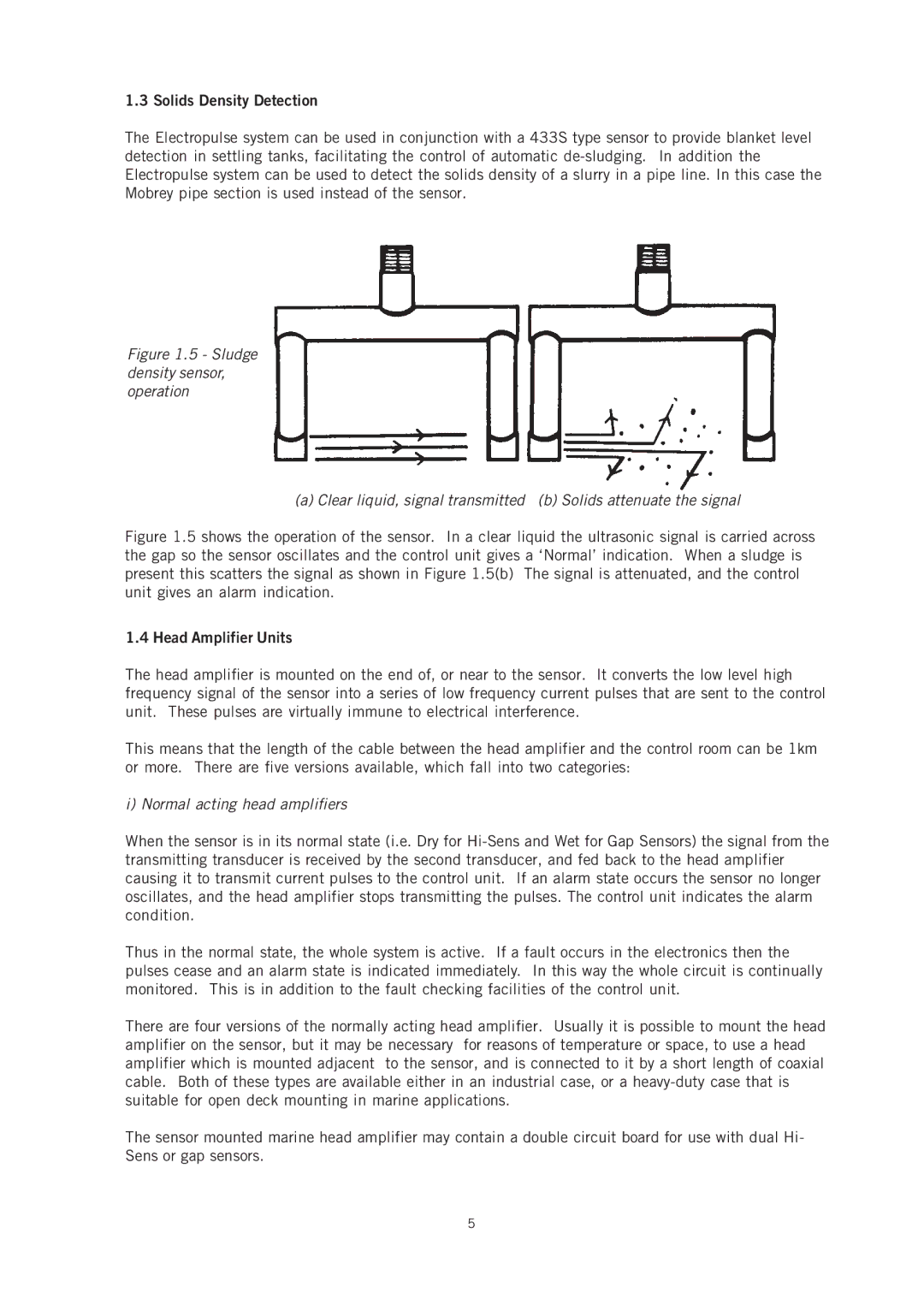

Figure 1.5 - Sludge density sensor, operation

(a) Clear liquid, signal transmitted (b) Solids attenuate the signal

Figure 1.5 shows the operation of the sensor. In a clear liquid the ultrasonic signal is carried across the gap so the sensor oscillates and the control unit gives a ‘Normal’ indication. When a sludge is present this scatters the signal as shown in Figure 1.5(b) The signal is attenuated, and the control unit gives an alarm indication.

1.4 Head Amplifier Units

The head amplifier is mounted on the end of, or near to the sensor. It converts the low level high frequency signal of the sensor into a series of low frequency current pulses that are sent to the control unit. These pulses are virtually immune to electrical interference.

This means that the length of the cable between the head amplifier and the control room can be 1km or more. There are five versions available, which fall into two categories:

i) Normal acting head amplifiers

When the sensor is in its normal state (i.e. Dry for

Thus in the normal state, the whole system is active. If a fault occurs in the electronics then the pulses cease and an alarm state is indicated immediately. In this way the whole circuit is continually monitored. This is in addition to the fault checking facilities of the control unit.

There are four versions of the normally acting head amplifier. Usually it is possible to mount the head amplifier on the sensor, but it may be necessary for reasons of temperature or space, to use a head amplifier which is mounted adjacent to the sensor, and is connected to it by a short length of coaxial cable. Both of these types are available either in an industrial case, or a

The sensor mounted marine head amplifier may contain a double circuit board for use with dual Hi- Sens or gap sensors.

5