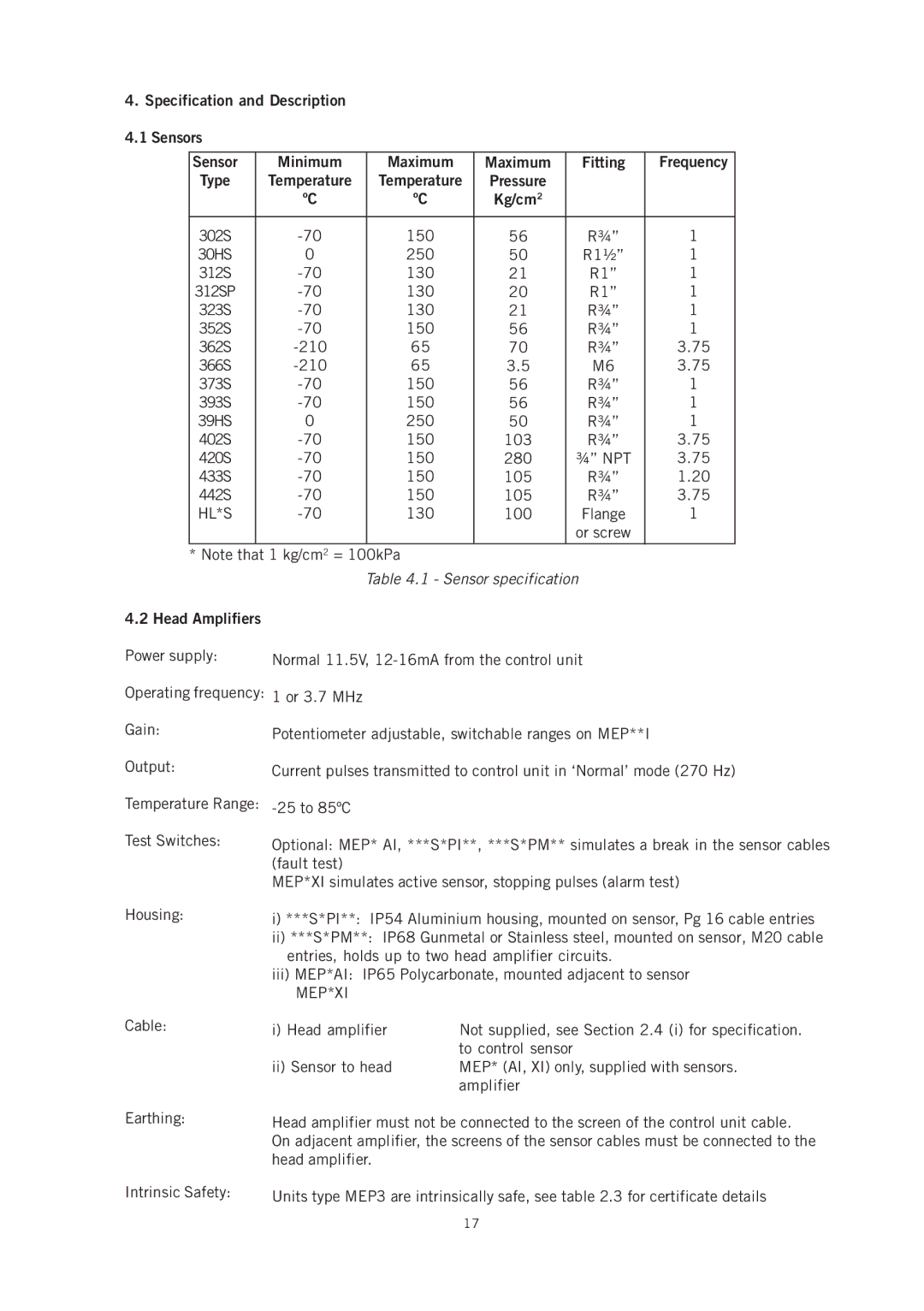

4.Specification and Description 4.1 Sensors

Sensor | Minimum | Maximum | Maximum | Fitting | Frequency |

Type | Temperature | Temperature | Pressure |

|

|

| ºC | ºC | Kg/cm2 |

|

|

|

|

|

|

|

|

302S | 150 | 56 | R¾” | 1 | |

30HS | 0 | 250 | 50 | R1½” | 1 |

312S | 130 | 21 | R1” | 1 | |

312SP | 130 | 20 | R1” | 1 | |

323S | 130 | 21 | R¾” | 1 | |

352S | 150 | 56 | R¾” | 1 | |

362S | 65 | 70 | R¾” | 3.75 | |

366S | 65 | 3.5 | M6 | 3.75 | |

373S | 150 | 56 | R¾” | 1 | |

393S | 150 | 56 | R¾” | 1 | |

39HS | 0 | 250 | 50 | R¾” | 1 |

402S | 150 | 103 | R¾” | 3.75 | |

420S | 150 | 280 | ¾” NPT | 3.75 | |

433S | 150 | 105 | R¾” | 1.20 | |

442S | 150 | 105 | R¾” | 3.75 | |

HL*S | 130 | 100 | Flange | 1 | |

|

|

|

| or screw |

|

* Note that 1 kg/cm2 = 100kPa

Table 4.1 - Sensor specification

4.2 Head Amplifiers

Power supply:

Operating frequency:

Gain:

Output:

Temperature Range:

Test Switches:

Normal 11.5V,

1 or 3.7 MHz

Potentiometer adjustable, switchable ranges on MEP**I

Current pulses transmitted to control unit in ‘Normal’ mode (270 Hz)

Optional: MEP* AI, ***S*PI**, ***S*PM** simulates a break in the sensor cables (fault test)

MEP*XI simulates active sensor, stopping pulses (alarm test)

Housing: | i) ***S*PI**: IP54 Aluminium housing, mounted on sensor, Pg 16 cable entries | |

| ii) ***S*PM**: IP68 Gunmetal or Stainless steel, mounted on sensor, M20 cable | |

| entries, holds up to two head amplifier circuits. | |

| iii) MEP*AI: IP65 Polycarbonate, mounted adjacent to sensor | |

| MEP*XI |

|

Cable: | i) Head amplifier | Not supplied, see Section 2.4 (i) for specification. |

|

| to control sensor |

| ii) Sensor to head | MEP* (AI, XI) only, supplied with sensors. |

|

| amplifier |

Earthing: | Head amplifier must not be connected to the screen of the control unit cable. | |

| On adjacent amplifier, the screens of the sensor cables must be connected to the | |

| head amplifier. |

|

Intrinsic Safety: | Units type MEP3 are intrinsically safe, see table 2.3 for certificate details | |

17