ENVISION RESIDENTIAL INSTALLATION MANUAL

Duct System

An air outlet collar is provided on vertical top air discharge units and all horizontal units to facilitate a duct connection (vertical bottomflow units have no collar). A flexible connector is recommended for discharge and return air duct connec- tions on metal duct systems. Uninsulated duct should be insulated with a minimum of

If the unit is connected to existing ductwork, check the duct system to ensure that it has the capacity to accommodate the air required for the unit application. If the duct is too small, as in the replacement of heating only systems, larger duct- work should be installed. All existing ductwork should be checked for leaks and repaired if necessary.

The duct system should be sized to handle the design airflow quietly and efficiently. To maximize sound attenuation of the unit blower, the supply and return plenums should include an internal duct liner of fiberglass or constructed of ductboard for the first few feet. On systems employing a sheet metal duct system, canvas connectors should be used between the unit and the ductwork. If air noise or excessive airflow is a problem, the blower speed can be changed.

CAUTION: Be sure to remove the shipping material from the blower discharge before con- necting ductwork.

Water Piping

The proper water flow must be provided to each unit whenever the unit operates. To assure proper flow, use pressure/temperature ports to determine the flow rate. These ports should be located at the supply and return water connections on the unit. The proper flow rate cannot be accurately set without measuring the water pressure drop through the

All source water connections on commercial units are fittings that accept a male pipe thread (MPT). Insert the connectors by hand, then tighten the fitting with a wrench to provide a leakproof joint. When con-

necting to an open loop (groundwater) system, thread any copper MPT fitting into the connector and tighten in the same manner as described above.

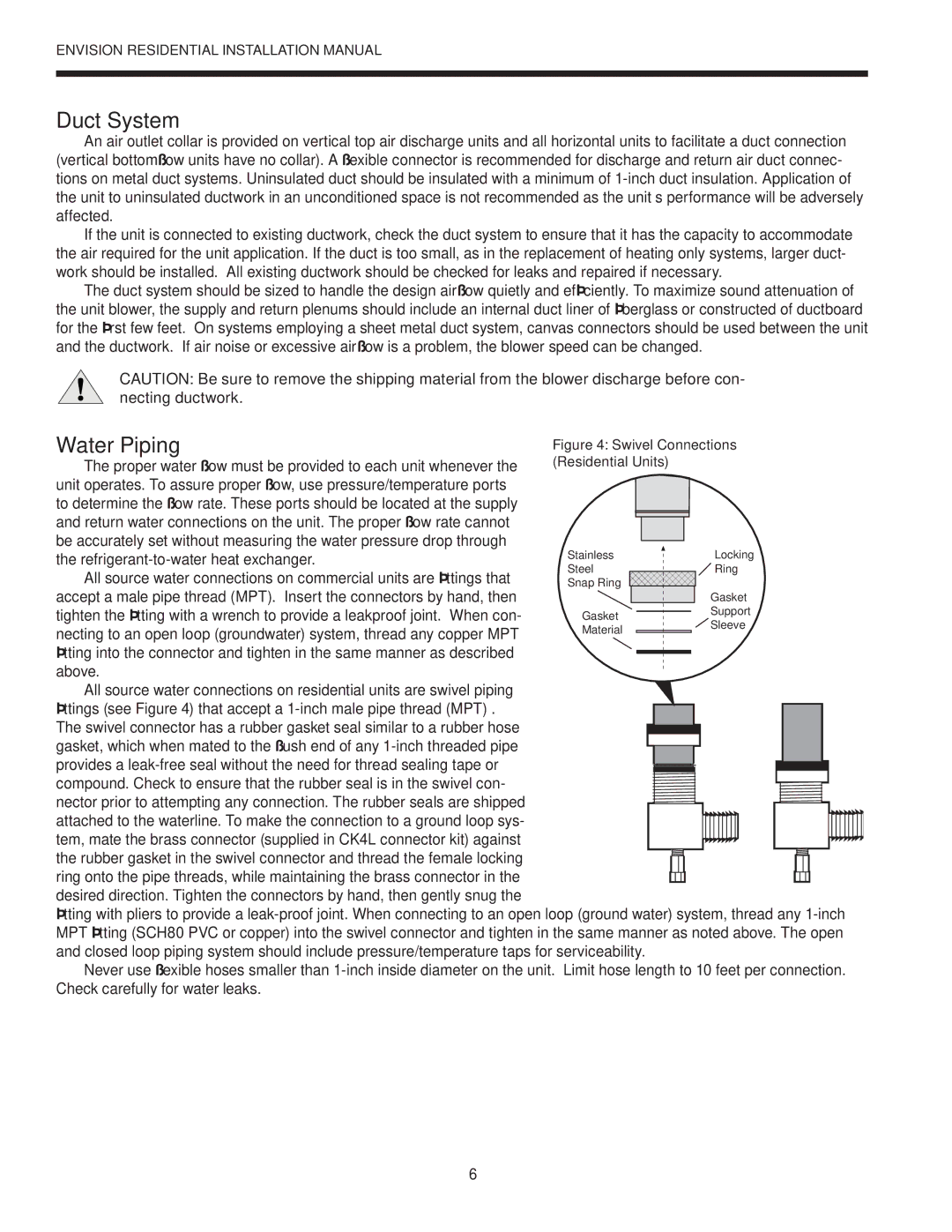

All source water connections on residential units are swivel piping fittings (see Figure 4) that accept a

The swivel connector has a rubber gasket seal similar to a rubber hose gasket, which when mated to the flush end of any

provides a

attached to the waterline. To make the connection to a ground loop sys- tem, mate the brass connector (supplied in CK4L connector kit) against the rubber gasket in the swivel connector and thread the female locking

ring onto the pipe threads, while maintaining the brass connector in the desired direction. Tighten the connectors by hand, then gently snug the

fitting with pliers to provide a

Never use flexible hoses smaller than

6