Table Extensions

Before using your planer, fold down the table extensions in the front and back of the tool (Fig. 7). After extended use, the table extensions may be slightly out of level. See Leveling the Table Extensions in the Maintenance section of this manual. NOTE: The outside edges of the extension tables are level with the base while the inside edges (closest to the cutter head) are below the edge of the base. This is set at the fac- tory to reduce unnecessary friction between the material and the table while providing adequate support at the two points (those farthest from the cutter head) on the tables that are integral to snipe prevention.

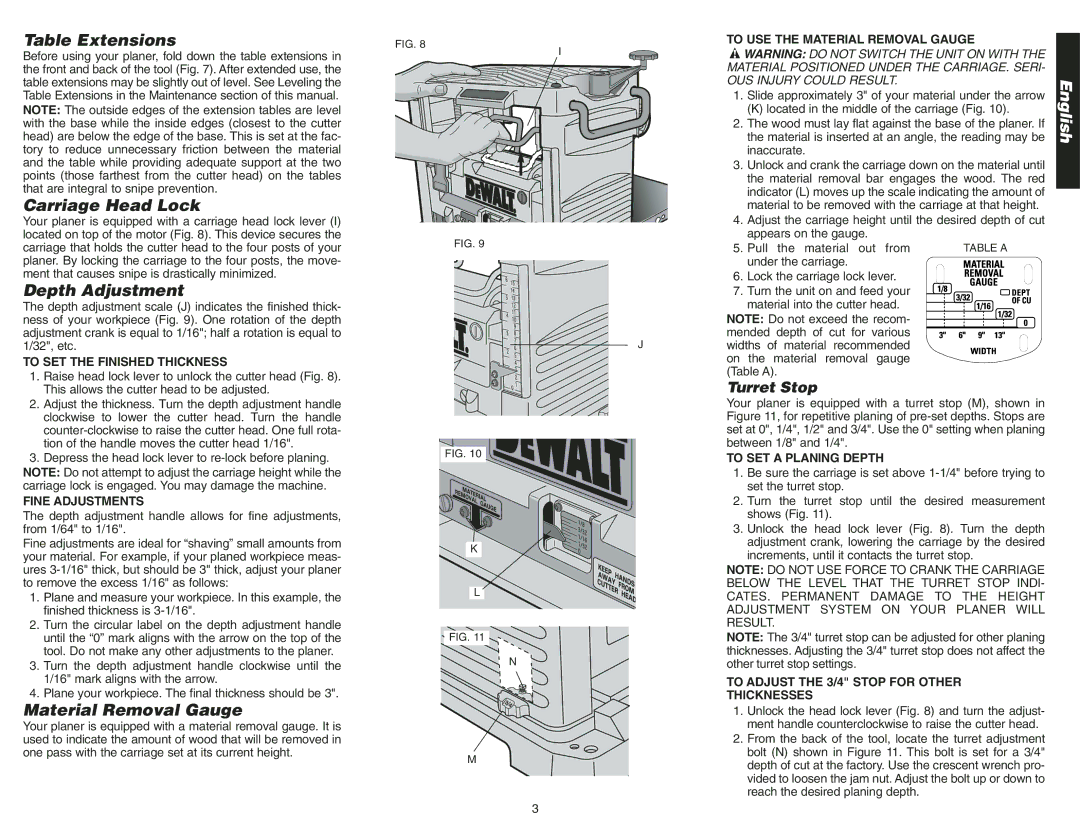

Carriage Head Lock

Your planer is equipped with a carriage head lock lever (I) located on top of the motor (Fig. 8). This device secures the carriage that holds the cutter head to the four posts of your planer. By locking the carriage to the four posts, the move- ment that causes snipe is drastically minimized.

Depth Adjustment

The depth adjustment scale (J) indicates the finished thick- ness of your workpiece (Fig. 9). One rotation of the depth adjustment crank is equal to 1/16"; half a rotation is equal to 1/32", etc.

TO SET THE FINISHED THICKNESS

1.Raise head lock lever to unlock the cutter head (Fig. 8). This allows the cutter head to be adjusted.

2.Adjust the thickness. Turn the depth adjustment handle clockwise to lower the cutter head. Turn the handle

3.Depress the head lock lever to

FINE ADJUSTMENTS

The depth adjustment handle allows for fine adjustments, from 1/64" to 1/16".

Fine adjustments are ideal for “shaving” small amounts from your material. For example, if your planed workpiece meas- ures

1.Plane and measure your workpiece. In this example, the finished thickness is

2.Turn the circular label on the depth adjustment handle until the “0” mark aligns with the arrow on the top of the tool. Do not make any other adjustments to the planer.

3.Turn the depth adjustment handle clockwise until the 1/16" mark aligns with the arrow.

4.Plane your workpiece. The final thickness should be 3".

Material Removal Gauge

Your planer is equipped with a material removal gauge. It is used to indicate the amount of wood that will be removed in one pass with the carriage set at its current height.

FIG. 8

I

R

FIG. 9

R | J |

FIG. 10 |

K |

L |

FIG. 11

N

3 | 4 |

M

TO USE THE MATERIAL REMOVAL GAUGE

![]() WARNING: DO NOT SWITCH THE UNIT ON WITH THE MATERIAL POSITIONED UNDER THE CARRIAGE. SERI- OUS INJURY COULD RESULT.

WARNING: DO NOT SWITCH THE UNIT ON WITH THE MATERIAL POSITIONED UNDER THE CARRIAGE. SERI- OUS INJURY COULD RESULT.

1.Slide approximately 3" of your material under the arrow

(K) located in the middle of the carriage (Fig. 10).

2.The wood must lay flat against the base of the planer. If the material is inserted at an angle, the reading may be inaccurate.

3.Unlock and crank the carriage down on the material until the material removal bar engages the wood. The red indicator (L) moves up the scale indicating the amount of material to be removed with the carriage at that height.

4.Adjust the carriage height until the desired depth of cut appears on the gauge.

5. Pull the material out from under the carriage.

6. Lock the carriage lock lever.

7. Turn the unit on and feed your material into the cutter head.

NOTE: Do not exceed the recom- mended depth of cut for various widths of material recommended on the material removal gauge (Table A).

Turret Stop

Your planer is equipped with a turret stop (M), shown in Figure 11, for repetitive planing of

TO SET A PLANING DEPTH

1.Be sure the carriage is set above

2.Turn the turret stop until the desired measurement shows (Fig. 11).

3.Unlock the head lock lever (Fig. 8). Turn the depth adjustment crank, lowering the carriage by the desired increments, until it contacts the turret stop.

NOTE: DO NOT USE FORCE TO CRANK THE CARRIAGE BELOW THE LEVEL THAT THE TURRET STOP INDI- CATES. PERMANENT DAMAGE TO THE HEIGHT ADJUSTMENT SYSTEM ON YOUR PLANER WILL RESULT.

NOTE: The 3/4" turret stop can be adjusted for other planing thicknesses. Adjusting the 3/4" turret stop does not affect the other turret stop settings.

TO ADJUST THE 3/4" STOP FOR OTHER

THICKNESSES

1.Unlock the head lock lever (Fig. 8) and turn the adjust- ment handle counterclockwise to raise the cutter head.

2.From the back of the tool, locate the turret adjustment bolt (N) shown in Figure 11. This bolt is set for a 3/4" depth of cut at the factory. Use the crescent wrench pro- vided to loosen the jam nut. Adjust the bolt up or down to reach the desired planing depth.

English

3