CHANGING THE PLANER KNIVES

![]() WARNING: DISCONNECT THE PLANER FROM THE POWER SOURCE BEFORE ATTEMPTING TO ACCESS OR CHANGE THE KNIVES.

WARNING: DISCONNECT THE PLANER FROM THE POWER SOURCE BEFORE ATTEMPTING TO ACCESS OR CHANGE THE KNIVES.

Your planer is equipped with a

TO CHANGE PLANER KNIVES

1.Use the

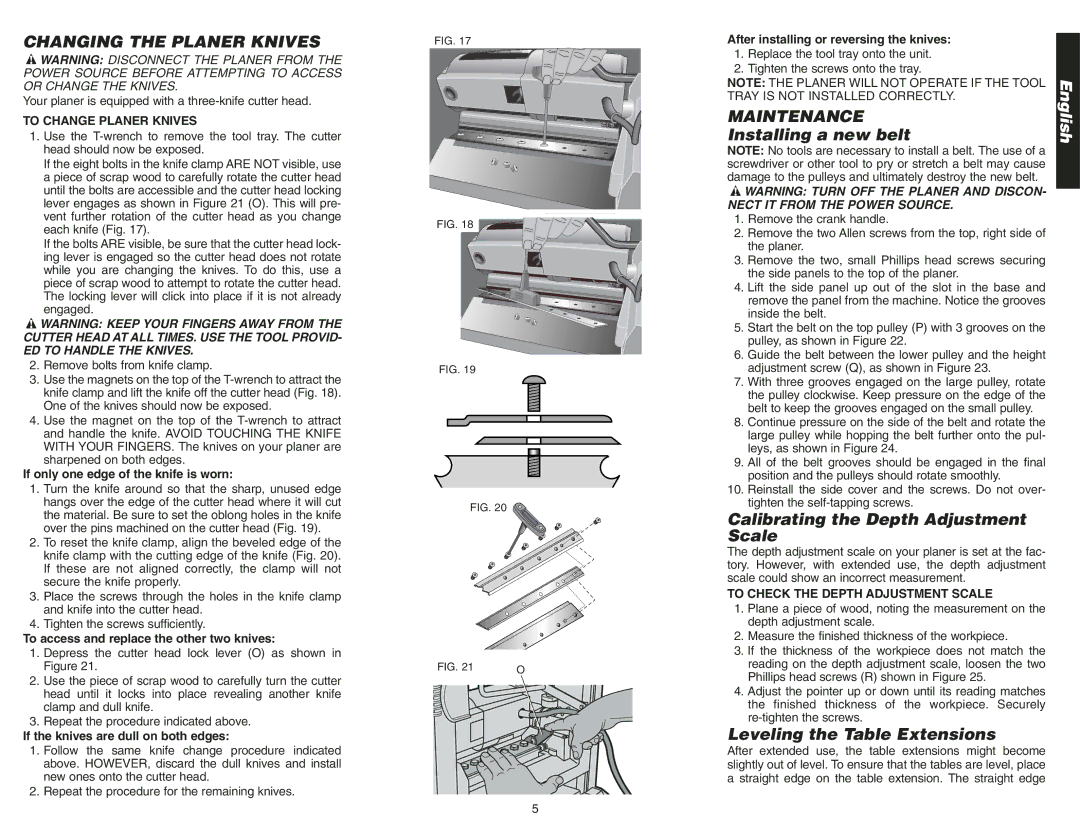

If the eight bolts in the knife clamp ARE NOT visible, use a piece of scrap wood to carefully rotate the cutter head until the bolts are accessible and the cutter head locking lever engages as shown in Figure 21 (O). This will pre- vent further rotation of the cutter head as you change each knife (Fig. 17).

If the bolts ARE visible, be sure that the cutter head lock- ing lever is engaged so the cutter head does not rotate while you are changing the knives. To do this, use a piece of scrap wood to attempt to rotate the cutter head. The locking lever will click into place if it is not already engaged.

![]() WARNING: KEEP YOUR FINGERS AWAY FROM THE CUTTER HEAD AT ALL TIMES. USE THE TOOL PROVID- ED TO HANDLE THE KNIVES.

WARNING: KEEP YOUR FINGERS AWAY FROM THE CUTTER HEAD AT ALL TIMES. USE THE TOOL PROVID- ED TO HANDLE THE KNIVES.

2.Remove bolts from knife clamp.

3.Use the magnets on the top of the

4.Use the magnet on the top of the

If only one edge of the knife is worn:

1.Turn the knife around so that the sharp, unused edge hangs over the edge of the cutter head where it will cut the material. Be sure to set the oblong holes in the knife over the pins machined on the cutter head (Fig. 19).

2.To reset the knife clamp, align the beveled edge of the knife clamp with the cutting edge of the knife (Fig. 20). If these are not aligned correctly, the clamp will not secure the knife properly.

3.Place the screws through the holes in the knife clamp and knife into the cutter head.

4.Tighten the screws sufficiently.

To access and replace the other two knives:

1.Depress the cutter head lock lever (O) as shown in Figure 21.

2.Use the piece of scrap wood to carefully turn the cutter head until it locks into place revealing another knife clamp and dull knife.

3.Repeat the procedure indicated above.

If the knives are dull on both edges:

1.Follow the same knife change procedure indicated above. HOWEVER, discard the dull knives and install new ones onto the cutter head.

2.Repeat the procedure for the remaining knives.

FIG. 17

FIG. 18 |

FIG. 19

FIG. 20

FIG. 21 | O |

After installing or reversing the knives:

1.Replace the tool tray onto the unit.

2.Tighten the screws onto the tray.

NOTE: THE PLANER WILL NOT OPERATE IF THE TOOL TRAY IS NOT INSTALLED CORRECTLY.

MAINTENANCE

Installing a new belt

NOTE: No tools are necessary to install a belt. The use of a screwdriver or other tool to pry or stretch a belt may cause damage to the pulleys and ultimately destroy the new belt.

![]() WARNING: TURN OFF THE PLANER AND DISCON- NECT IT FROM THE POWER SOURCE.

WARNING: TURN OFF THE PLANER AND DISCON- NECT IT FROM THE POWER SOURCE.

1.Remove the crank handle.

2.Remove the two Allen screws from the top, right side of the planer.

3.Remove the two, small Phillips head screws securing the side panels to the top of the planer.

4.Lift the side panel up out of the slot in the base and remove the panel from the machine. Notice the grooves inside the belt.

5.Start the belt on the top pulley (P) with 3 grooves on the pulley, as shown in Figure 22.

6.Guide the belt between the lower pulley and the height adjustment screw (Q), as shown in Figure 23.

7.With three grooves engaged on the large pulley, rotate the pulley clockwise. Keep pressure on the edge of the belt to keep the grooves engaged on the small pulley.

8.Continue pressure on the side of the belt and rotate the large pulley while hopping the belt further onto the pul- leys, as shown in Figure 24.

9.All of the belt grooves should be engaged in the final position and the pulleys should rotate smoothly.

10.Reinstall the side cover and the screws. Do not over- tighten the

Calibrating the Depth Adjustment Scale

The depth adjustment scale on your planer is set at the fac- tory. However, with extended use, the depth adjustment scale could show an incorrect measurement.

TO CHECK THE DEPTH ADJUSTMENT SCALE

1.Plane a piece of wood, noting the measurement on the depth adjustment scale.

2.Measure the finished thickness of the workpiece.

3.If the thickness of the workpiece does not match the reading on the depth adjustment scale, loosen the two Phillips head screws (R) shown in Figure 25.

4.Adjust the pointer up or down until its reading matches the finished thickness of the workpiece. Securely

Leveling the Table Extensions

After extended use, the table extensions might become slightly out of level. To ensure that the tables are level, place a straight edge on the table extension. The straight edge

English

5