Noncontact Food Safety Thermometer

Noncontact Temperature Measurement Applications

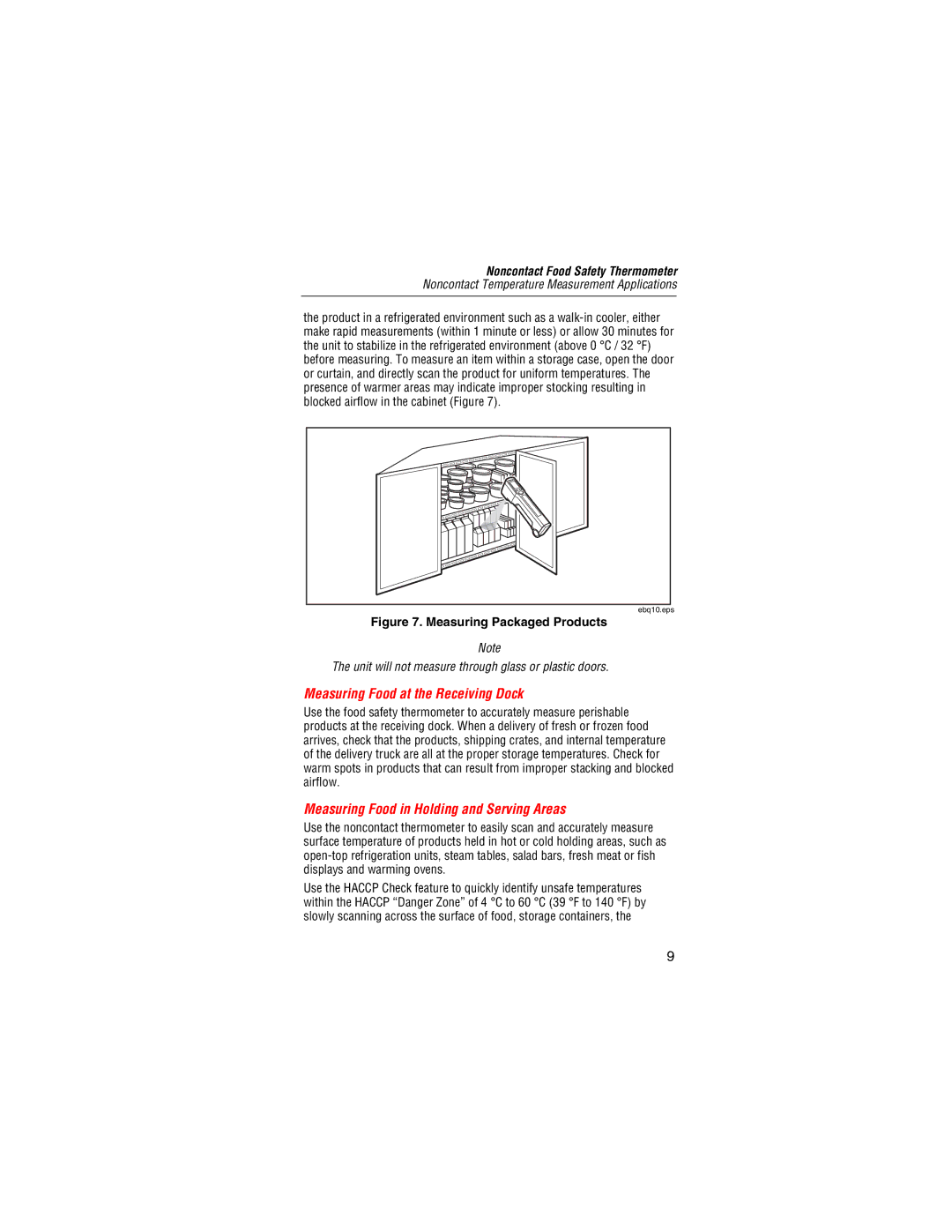

the product in a refrigerated environment such as a

ebq10.eps

Figure 7. Measuring Packaged Products

Note

The unit will not measure through glass or plastic doors.

Measuring Food at the Receiving Dock

Use the food safety thermometer to accurately measure perishable products at the receiving dock. When a delivery of fresh or frozen food arrives, check that the products, shipping crates, and internal temperature of the delivery truck are all at the proper storage temperatures. Check for warm spots in products that can result from improper stacking and blocked airflow.

Measuring Food in Holding and Serving Areas

Use the noncontact thermometer to easily scan and accurately measure surface temperature of products held in hot or cold holding areas, such as

Use the HACCP Check feature to quickly identify unsafe temperatures within the HACCP “Danger Zone” of 4 °C to 60 °C (39 °F to 140 °F) by slowly scanning across the surface of food, storage containers, the

9