tion failure situation may be encountered in which all components appear to be serviceable and the microamp reading is within specification, but the unit nevertheless goes into ignition failure during operation. The probable cause in this case is an intermittent failure of an ignition module. When the unit is opened up for troubleshooting, the module cools down enough to operate correctly, but when the unit is again closed up and placed back into service, the module heats up and fails.

PROBLEMS RELATED TO THE GAS VALVE

If the problem is not in the 24 VAC circuit, it is most likely in the gas valve itself, but before replac- ing the gas valve, refer to the troubleshooting guide TROUBLESHOOTING THE GAS VALVE.

6.7.2 Improper Burner Functioning

With problems in this category, the burner ignites but exhibits abnormal characteristics such as “popping,” dark spots on the burner ceramics, fluctuating flame intensity, and flames shooting out of the flue.

“Popping” indicates delayed ignition. In this condition, the main gas valve is opening but the burner is not immediately lighting. When ignition does take place, the excess gas “explodes” into flame, rather than smoothly igniting.

The primary causes of popping are:

Incorrect or fluctuating gas pressure

A defective, dirty, or incorrectly adjusted combustion air blower

Inadequate

Heat damage to the controller or ignition module

A cracked ignitor or broken/loose ignition wire

A defective ignition module

A cracked burner tile.

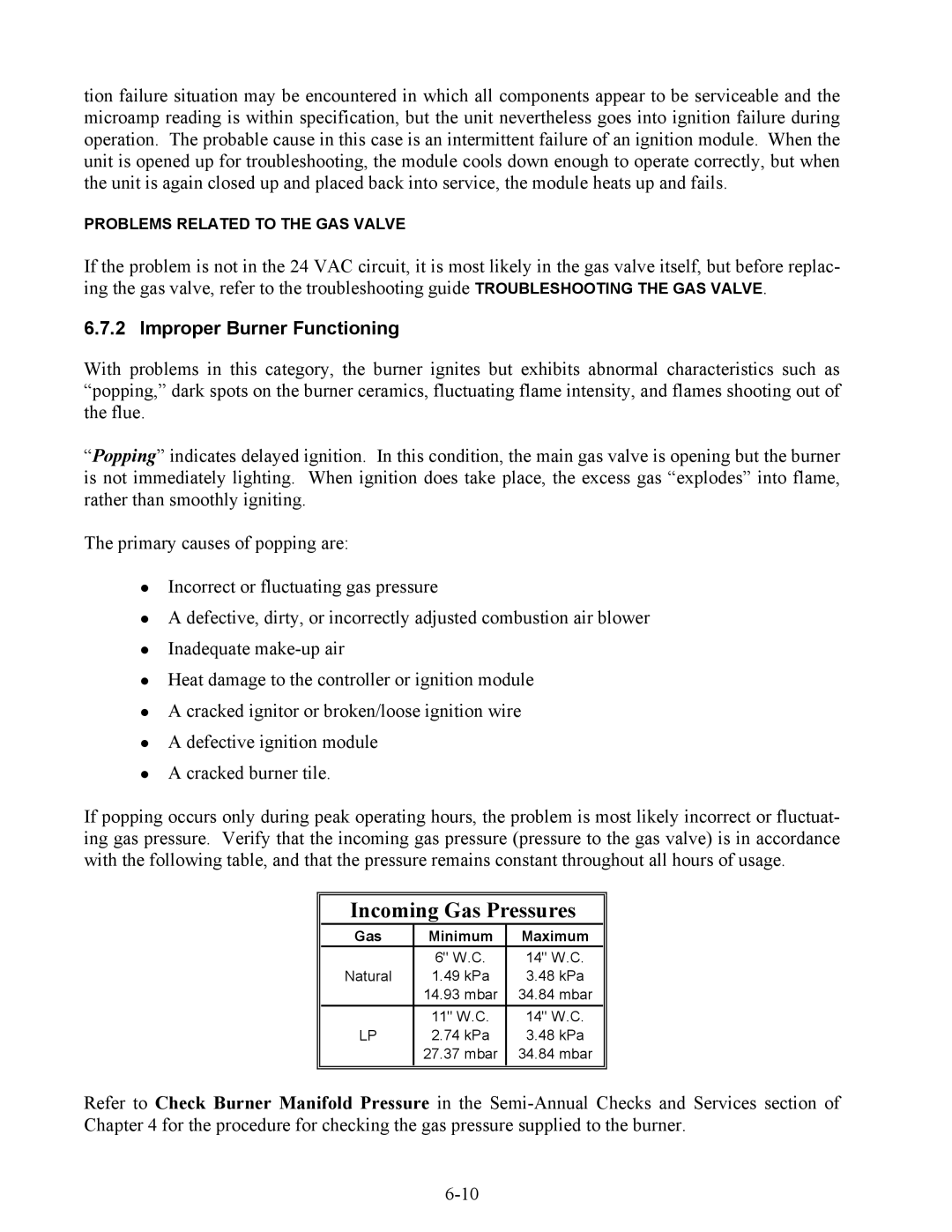

If popping occurs only during peak operating hours, the problem is most likely incorrect or fluctuat- ing gas pressure. Verify that the incoming gas pressure (pressure to the gas valve) is in accordance with the following table, and that the pressure remains constant throughout all hours of usage.

Incoming Gas Pressures

Gas | Minimum | Maximum |

| 6" W.C. | 14" W.C. |

Natural | 1.49 kPa | 3.48 kPa |

| 14.93 mbar | 34.84 mbar |

| 11" W.C. | 14" W.C. |

LP | 2.74 kPa | 3.48 kPa |

| 27.37 mbar | 34.84 mbar |

Refer to Check Burner Manifold Pressure in the