4. Reinstall tube and bend it so that the opening is pointing downward.

4.3Semi-Annual Checks and Service

Check Burner Manifold Pressure

![]() WARNING

WARNING

This task should be performed by qualified service personnel only.

![]() WARNING

WARNING

The frypot must be filled with water or cooking oil/shortening during this procedure.

1.Ensure that the gas valve knob is in the OFF position.

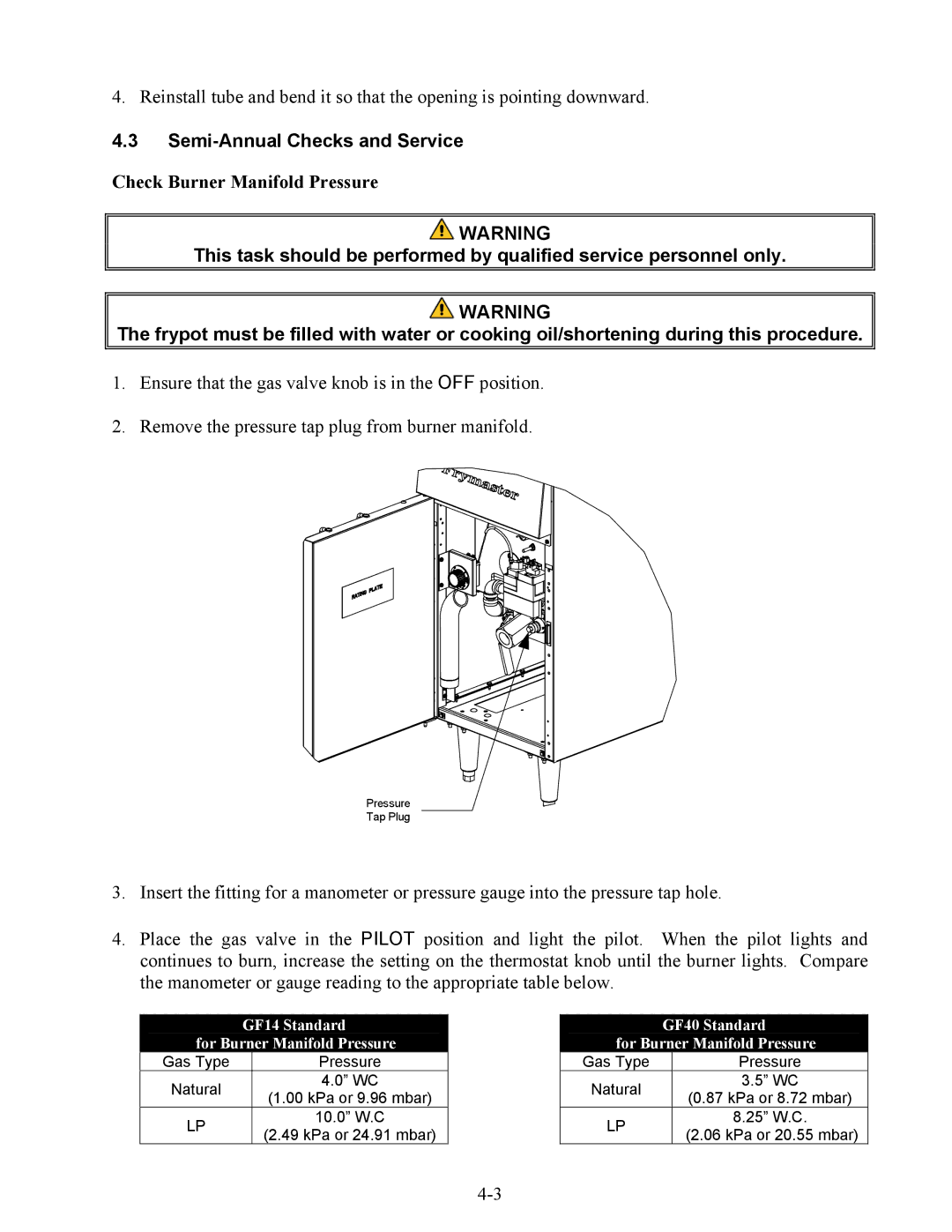

2.Remove the pressure tap plug from burner manifold.

Pressure

Tap Plug

3.Insert the fitting for a manometer or pressure gauge into the pressure tap hole.

4.Place the gas valve in the PILOT position and light the pilot. When the pilot lights and continues to burn, increase the setting on the thermostat knob until the burner lights. Compare the manometer or gauge reading to the appropriate table below.

GF14 Standard

for Burner Manifold Pressure

Gas Type | Pressure | |

Natural | 4.0” WC | |

(1.00 kPa or 9.96 mbar) | ||

| ||

LP | 10.0” W.C | |

(2.49 kPa or 24.91 mbar) | ||

|

GF40 Standard

for Burner Manifold Pressure

Gas Type | Pressure | |

Natural | 3.5” WC | |

(0.87 kPa or 8.72 mbar) | ||

| ||

LP | 8.25” W.C. | |

(2.06 kPa or 20.55 mbar) | ||

|