Y/KSCF/C/HC18G specifications

The Frymaster Y/KSCF/C/HC18G is a modern deep fryer designed for high volume cooking, particularly suited for the fast-paced demands of commercial kitchens. With its robust engineering and innovative technologies, this fryer delivers exceptional performance, ensuring efficiency and consistency in food quality.One of the standout features of the Frymaster Y/KSCF/C/HC18G is its high-capacity frying capability. Designed to accommodate large batches, it can hold significant amounts of oil, allowing for the frying of various foods simultaneously, thus optimizing cooking times. This fryer is ideal for establishments that requires consistent output, such as restaurants, cafeterias, and food trucks.

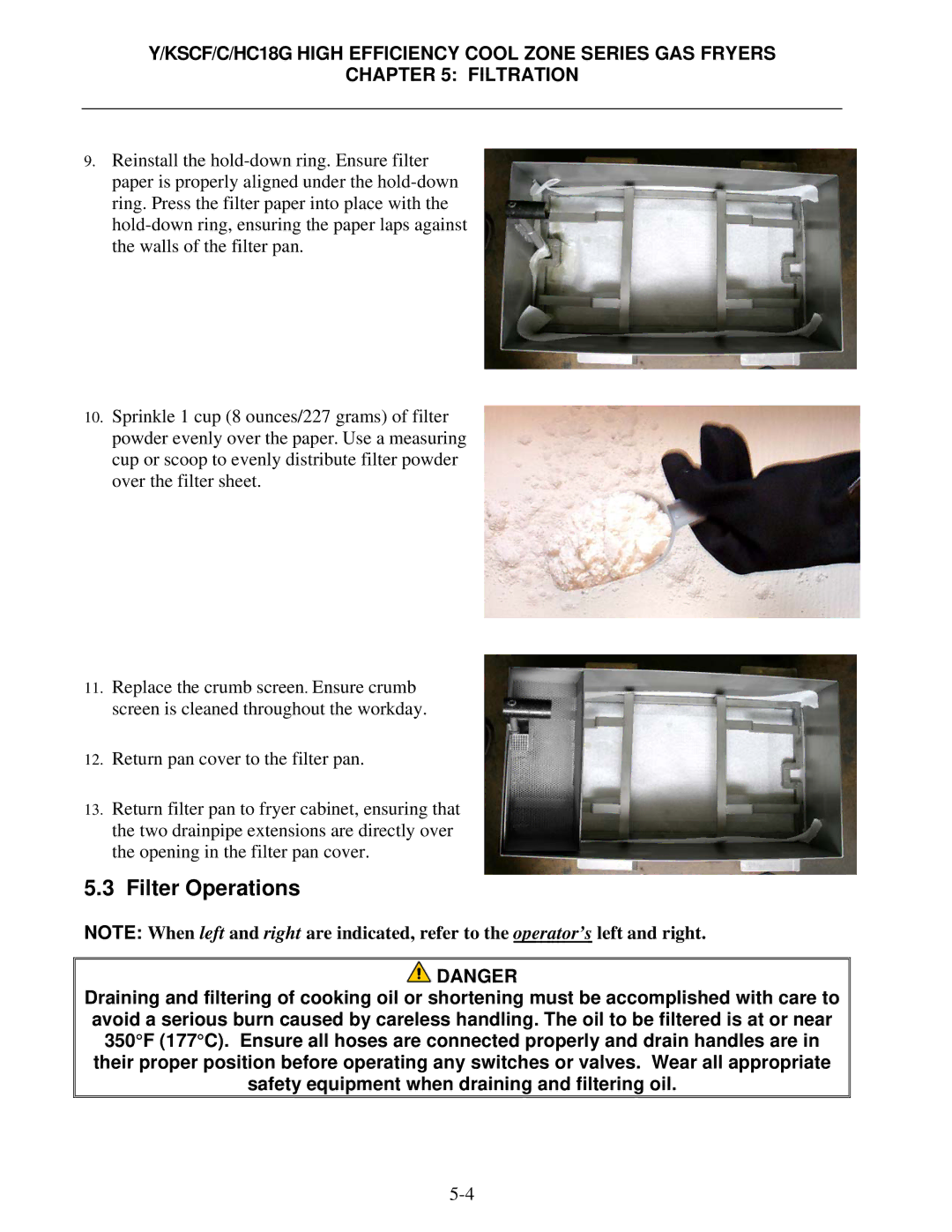

The Y/KSCF/C/HC18G incorporates advanced oil filtration technology, which is crucial for maintaining the quality of the frying oil over extended periods. This system automatically filters oil during idle times and prior to cooking cycles, removing food particles and prolonging the life of the oil, ultimately leading to cost savings for businesses. The filtration process also contributes to better-tasting foods by reducing the build-up of unwanted residues.

Another innovative characteristic of this fryer is its precise temperature control. The Frymaster Y/KSCF/C/HC18G utilizes a digital control system that allows operators to set and monitor cooking temperatures accurately. This feature helps achieve optimal frying conditions for different food types, ensuring that items are cooked evenly and to the desired crispness.

Energy efficiency is another important aspect of the Frymaster Y/KSCF/C/HC18G. Equipped with high-performing heating elements, this fryer heats up quickly and maintains temperature consistently, reducing energy consumption. Features such as programmable cook times and automatic shut-off further enhance energy efficiency, contributing to lower operational costs.

Safety is paramount in commercial kitchens, and the Frymaster Y/KSCF/C/HC18G is designed with multiple safety features. It includes an automatic safety shut-off system that activates if the fryer reaches dangerously high temperatures, thereby preventing overheating and potential hazards.

In summary, the Frymaster Y/KSCF/C/HC18G is an outstanding deep fryer that combines high capacity, efficient oil filtration, precise controls, energy-saving features, and robust safety mechanisms. It is an ideal choice for operators seeking reliability and excellence in their frying operations, ensuring that they can meet customer demands without compromising on quality.