640t – Installation and Operating Instructions

Emergency Stop and Table

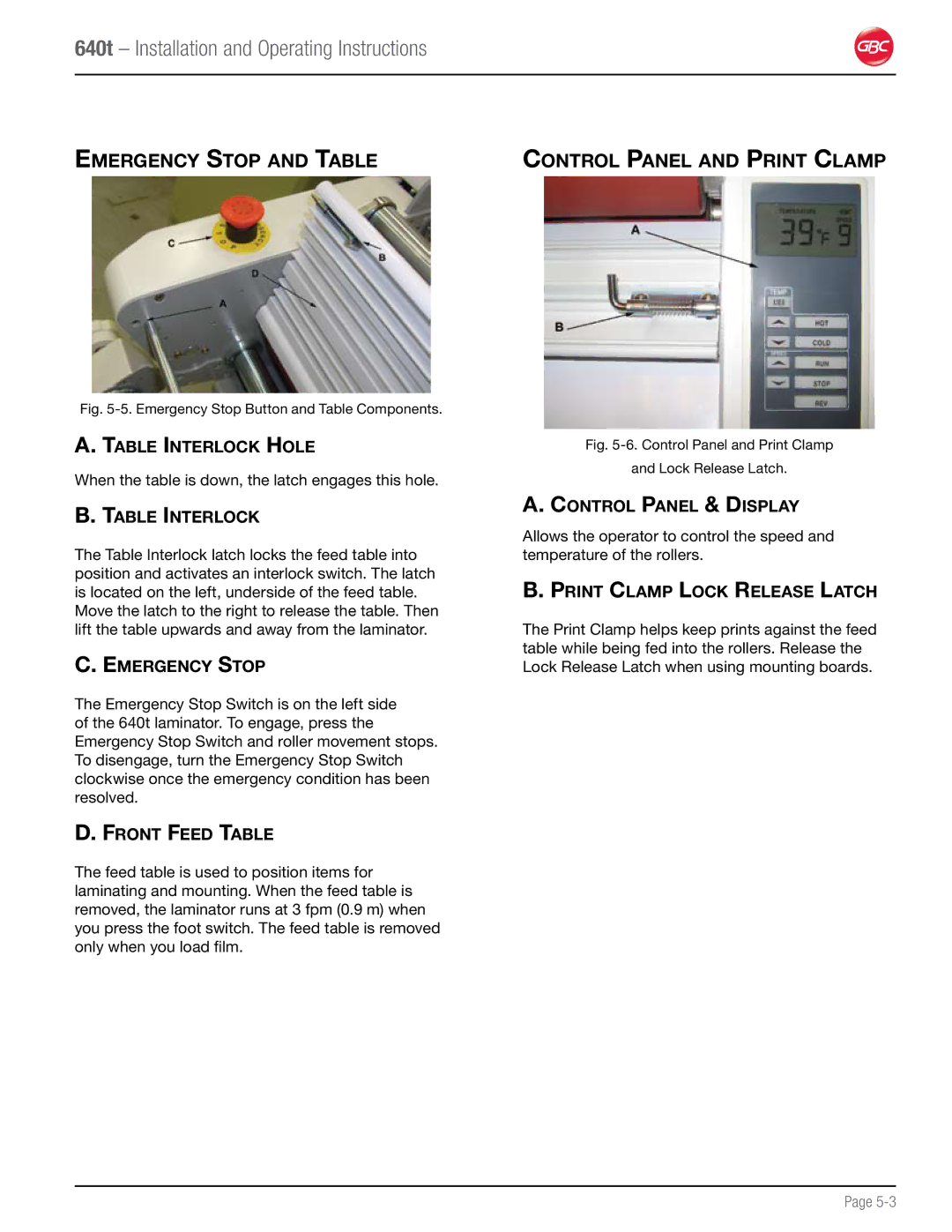

Fig. 5-5. Emergency Stop Button and Table Components.

A.Table Interlock Hole

When the table is down, the latch engages this hole.

B.Table Interlock

The Table Interlock latch locks the feed table into position and activates an interlock switch. The latch is located on the left, underside of the feed table. Move the latch to the right to release the table. Then lift the table upwards and away from the laminator.

C.Emergency Stop

The Emergency Stop Switch is on the left side of the 640t laminator. To engage, press the Emergency Stop Switch and roller movement stops. To disengage, turn the Emergency Stop Switch clockwise once the emergency condition has been resolved.

D. Front Feed Table

The feed table is used to position items for laminating and mounting. When the feed table is removed, the laminator runs at 3 fpm (0.9 m) when you press the foot switch. The feed table is removed only when you load film.

Control Panel and Print Clamp

Fig. 5-6. Control Panel and Print Clamp

and Lock Release Latch.

A.Control Panel & Display

Allows the operator to control the speed and temperature of the rollers.

B.Print Clamp Lock Release Latch

The Print Clamp helps keep prints against the feed table while being fed into the rollers. Release the Lock Release Latch when using mounting boards.

Page