640t – Installation and Operating Instructions

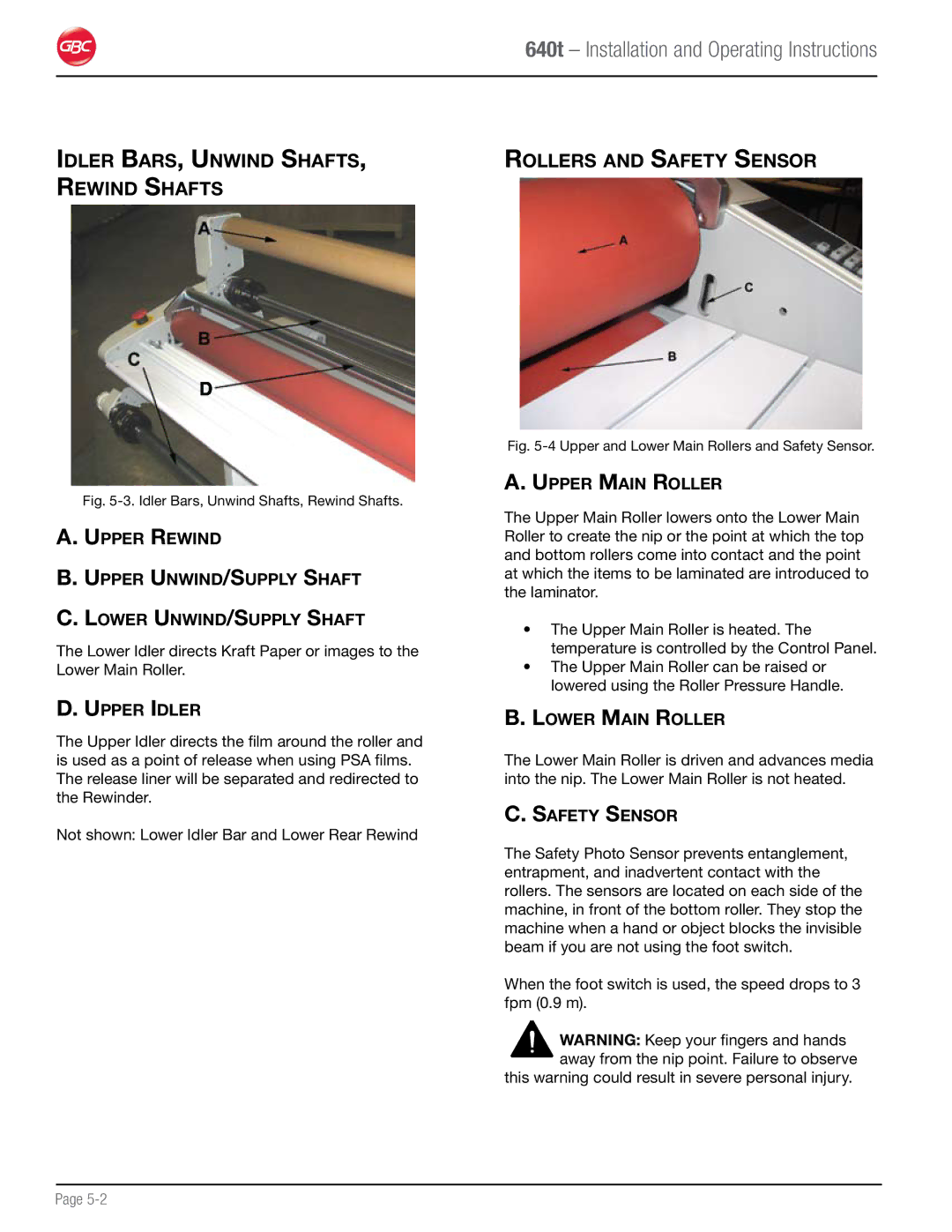

Idler Bars, Unwind Shafts, Rewind Shafts

Fig. 5-3. Idler Bars, Unwind Shafts, Rewind Shafts.

A.Upper Rewind

B.Upper Unwind/Supply Shaft

C.Lower Unwind/Supply Shaft

The Lower Idler directs Kraft Paper or images to the Lower Main Roller.

D.Upper Idler

The Upper Idler directs the film around the roller and is used as a point of release when using PSA films. The release liner will be separated and redirected to the Rewinder.

Not shown: Lower Idler Bar and Lower Rear Rewind

Rollers and Safety Sensor

Fig. 5-4 Upper and Lower Main Rollers and Safety Sensor.

A.Upper Main Roller

The Upper Main Roller lowers onto the Lower Main Roller to create the nip or the point at which the top and bottom rollers come into contact and the point at which the items to be laminated are introduced to the laminator.

•The Upper Main Roller is heated. The temperature is controlled by the Control Panel.

•The Upper Main Roller can be raised or lowered using the Roller Pressure Handle.

B.Lower Main Roller

The Lower Main Roller is driven and advances media into the nip. The Lower Main Roller is not heated.

C.Safety Sensor

The Safety Photo Sensor prevents entanglement, entrapment, and inadvertent contact with the rollers. The sensors are located on each side of the machine, in front of the bottom roller. They stop the machine when a hand or object blocks the invisible beam if you are not using the foot switch.

When the foot switch is used, the speed drops to 3 fpm (0.9 m).

WARNING: Keep your fingers and hands away from the nip point. Failure to observe

this warning could result in severe personal injury.

Page