Water Usage Pattern

The other reserve option allows the control to adjust the reserve based upon the historical water usage pattern of the system. The control keeps track of the water usage for each day of the week and uses that day’s average usage multiplied by 1.2 as the reserve for that day. Every day at the Time of Regeneration, the control recalculates the day’s average water usage. If less than 10% of a day’s average water usage is used, the control will not change the day’s average. If more than twice the day’s average is used, the control uses the actual usage in the reserve calculation.

Since a new installation has no history of water usage, the control multiplies the percent of capacity value set in parameter P16 by the total system capacity to determine starting average for each day of the week. The factory set default value for P16 is 30 which means that 30% of the total system capacity is used for the starting average for each day.

Program parameter P15 is also used to select whether the control waits until the Time of Regeneration set in parameter P2 to start a regeneration, or if the control should begin a regeneration immediately when the capacity remaining is less than the reserve.

Removing the Valve Assembly for Servicing

1.Unplug the power cord.

2.Shut off water supply or put bypass valve(s) into bypass position.

3.Remove cover and with screwdriver, relieve tank pressure by pushing open valve No. 7 (rear flapper) on control as shown (Figure 9).

Preventive Maintenance

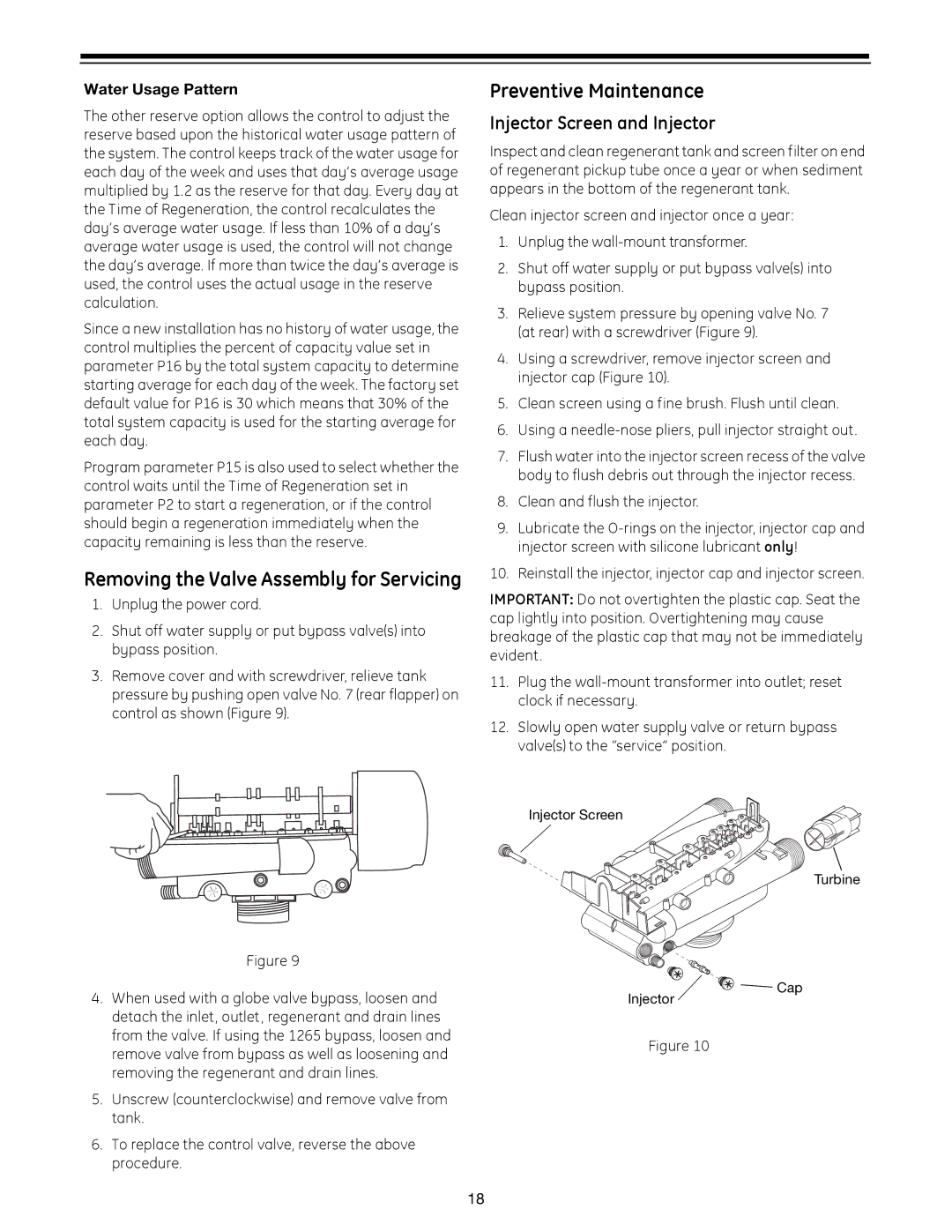

Injector Screen and Injector

Inspect and clean regenerant tank and screen filter on end of regenerant pickup tube once a year or when sediment appears in the bottom of the regenerant tank.

Clean injector screen and injector once a year:

1.Unplug the

2.Shut off water supply or put bypass valve(s) into bypass position.

3.Relieve system pressure by opening valve No. 7 (at rear) with a screwdriver (Figure 9).

4.Using a screwdriver, remove injector screen and injector cap (Figure 10).

5.Clean screen using a fine brush. Flush until clean.

6.Using a

7.Flush water into the injector screen recess of the valve body to flush debris out through the injector recess.

8.Clean and flush the injector.

9.Lubricate the

10.Reinstall the injector, injector cap and injector screen.

IMPORTANT: Do not overtighten the plastic cap. Seat the cap lightly into position. Overtightening may cause breakage of the plastic cap that may not be immediately evident.

11.Plug the

12.Slowly open water supply valve or return bypass valve(s) to the “service” position.

Figure 9

4.When used with a globe valve bypass, loosen and detach the inlet, outlet, regenerant and drain lines from the valve. If using the 1265 bypass, loosen and remove valve from bypass as well as loosening and removing the regenerant and drain lines.

5.Unscrew (counterclockwise) and remove valve from tank.

6.To replace the control valve, reverse the above procedure.

Injector Screen

Turbine

![]()

![]() Cap

Cap

Injector

Figure 10

18