Installation

All plumbing and electrical connections must conform to local codes.

Inspect unit carefully for carrier shortage or shipping damage.

Location Selection

1.The distance between the unit and a drain should be as short as possible.

2.If it is likely that supplementary water treatment equipment will be required, make certain adequate additional space is available.

3.Since salt must be added periodically to the regenerant tank, the location should be easily accessible.

4.Do not install any unit closer to a water heater than a total run of 10 feet (3 m) of piping between the outlet of the conditioner and the inlet to the heater. Water heaters can sometimes overheat to the extent they will transmit heat back along the cold pipe into the unit control valve.

Hot water can severely damage the conditioner. A

5.Do not locate unit where it or its connections

(including the drain and overflow lines) will ever be subjected to room temperatures under 34oF (1oC) or over 120oF (49oC).

6.Do not install unit near acid or acid fumes.

7.The use of resin cleaners in an unvented area is not recommended.

Water Line Connection

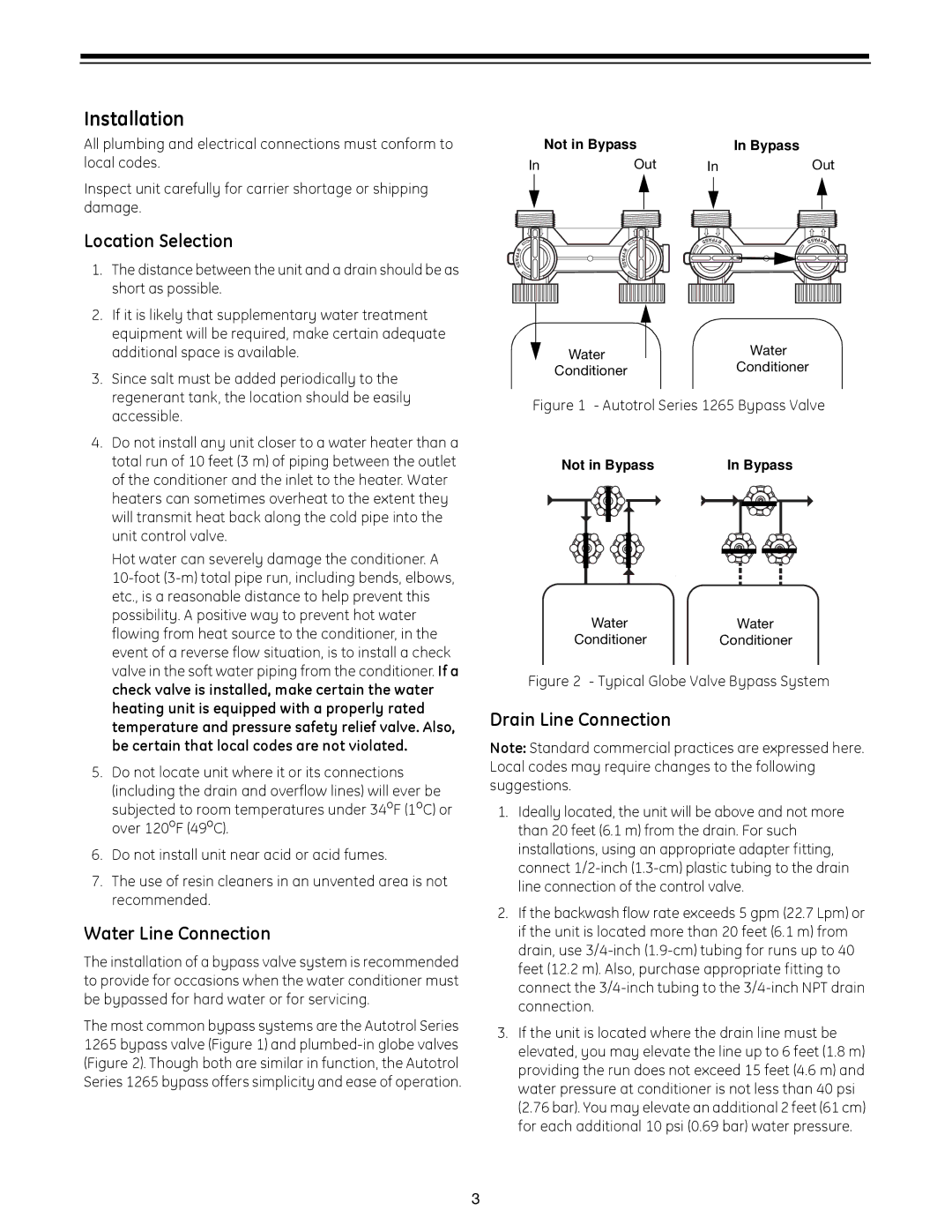

The installation of a bypass valve system is recommended to provide for occasions when the water conditioner must be bypassed for hard water or for servicing.

The most common bypass systems are the Autotrol Series 1265 bypass valve (Figure 1) and

| Not in Bypass |

| In Bypass |

In | Out | In | Out |

SAP | Y B | SAP | Y B |

S | S |

Y | B | Y | B |

|

| ||

P |

| P |

|

A | A | ||

S | S | ||

S | S | ||

WaterWater

ConditionerConditioner

Figure 1 - Autotrol Series 1265 Bypass Valve

Not in Bypass | In Bypass | ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WaterWater

Conditioner Conditioner

WaterWater

Figure 2 - Typical Globe Valve Bypass System

Drain Line Connection

Note: Standard commercial practices are expressed here. Local codes may require changes to the following suggestions.

1.Ideally located, the unit will be above and not more than 20 feet (6.1 m) from the drain. For such installations, using an appropriate adapter fitting, connect

2.If the backwash flow rate exceeds 5 gpm (22.7 Lpm) or if the unit is located more than 20 feet (6.1 m) from drain, use

3.If the unit is located where the drain line must be elevated, you may elevate the line up to 6 feet (1.8 m) providing the run does not exceed 15 feet (4.6 m) and water pressure at conditioner is not less than 40 psi (2.76 bar). You may elevate an additional 2 feet (61 cm) for each additional 10 psi (0.69 bar) water pressure.

3