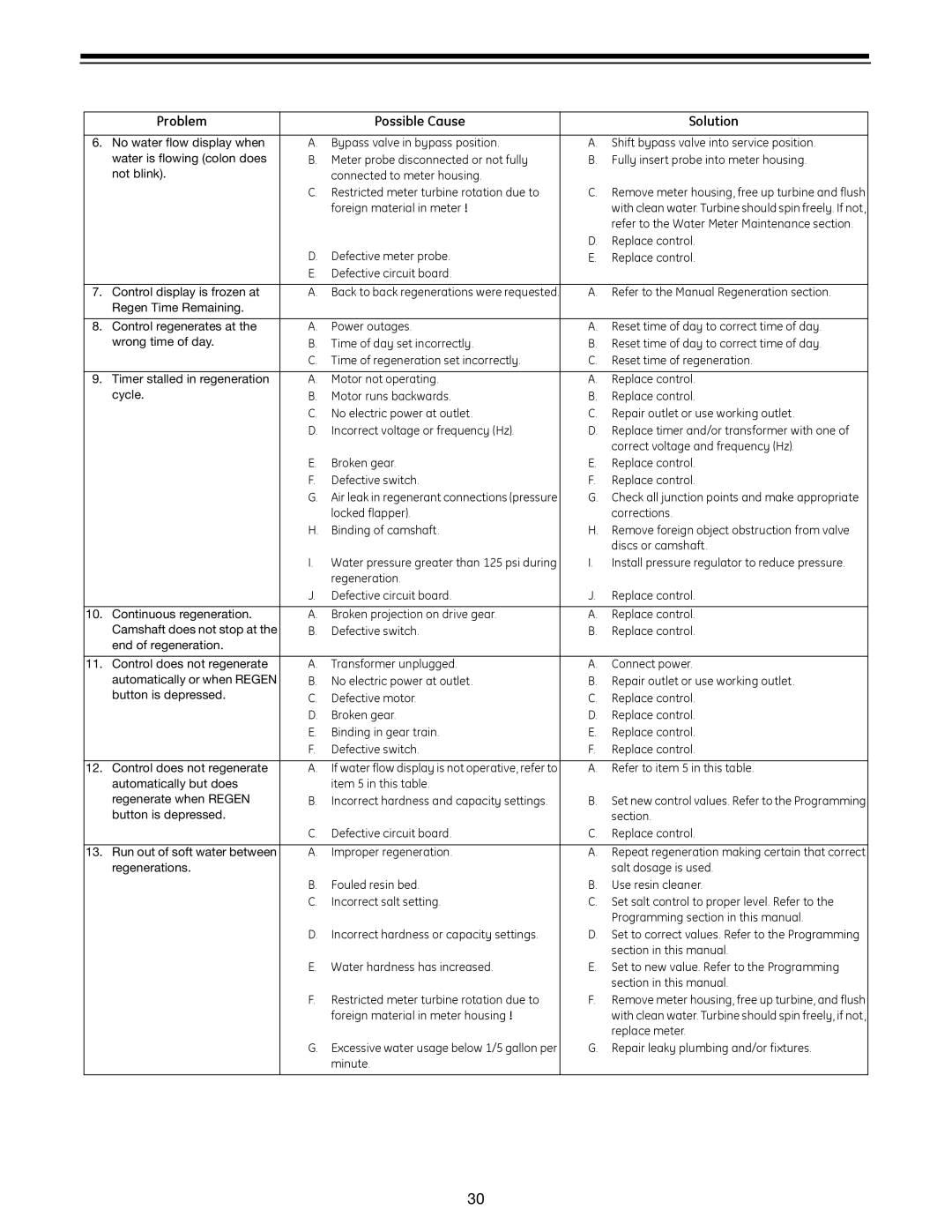

| Problem |

| Possible Cause |

| Solution |

|

|

|

|

| |

6. No water flow display when | A. | Bypass valve in bypass position. | A. | Shift bypass valve into service position. | |

| water is flowing (colon does | B. | Meter probe disconnected or not fully | B. | Fully insert probe into meter housing. |

| not blink). |

| connected to meter housing. |

|

|

|

| C. | Restricted meter turbine rotation due to | C. | Remove meter housing, free up turbine and flush |

|

|

| foreign material in meter ! |

| with clean water. Turbine should spin freely. If not, |

|

|

|

|

| refer to the Water Meter Maintenance section. |

|

|

|

| D. | Replace control. |

|

| D. | Defective meter probe. | E. | Replace control. |

|

| E. | Defective circuit board. |

|

|

|

|

|

|

| |

7. Control display is frozen at | A. | Back to back regenerations were requested. | A. | Refer to the Manual Regeneration section. | |

| Regen Time Remaining. |

|

|

|

|

|

|

|

|

|

|

8. | Control regenerates at the | A. | Power outages. | A. | Reset time of day to correct time of day. |

| wrong time of day. | B. | Time of day set incorrectly. | B. | Reset time of day to correct time of day. |

|

| C. | Time of regeneration set incorrectly. | C. | Reset time of regeneration. |

|

|

|

|

| |

9. Timer stalled in regeneration | A. | Motor not operating. | A. | Replace control. | |

| cycle. | B. | Motor runs backwards. | B. | Replace control. |

|

| C. | No electric power at outlet. | C. | Repair outlet or use working outlet. |

|

| D. | Incorrect voltage or frequency (Hz). | D. | Replace timer and/or transformer with one of |

|

|

|

|

| correct voltage and frequency (Hz). |

|

| E. | Broken gear. | E. | Replace control. |

|

| F. | Defective switch. | F. | Replace control. |

|

| G. | Air leak in regenerant connections (pressure | G. | Check all junction points and make appropriate |

|

|

| locked flapper). |

| corrections. |

|

| H. | Binding of camshaft. | H. | Remove foreign object obstruction from valve |

|

|

|

|

| discs or camshaft. |

|

| I. | Water pressure greater than 125 psi during | I. | Install pressure regulator to reduce pressure. |

|

|

| regeneration. |

|

|

|

| J. | Defective circuit board. | J. | Replace control. |

|

|

|

|

|

|

10. | Continuous regeneration. | A. | Broken projection on drive gear. | A. | Replace control. |

| Camshaft does not stop at the | B. | Defective switch. | B. | Replace control. |

| end of regeneration. |

|

|

|

|

|

|

|

|

|

|

11. | Control does not regenerate | A. | Transformer unplugged. | A. | Connect power. |

| automatically or when REGEN | B. | No electric power at outlet. | B. | Repair outlet or use working outlet. |

| button is depressed. | C. | Defective motor. | C. | Replace control. |

|

| D. | Broken gear. | D. | Replace control. |

|

| E. | Binding in gear train. | E. | Replace control. |

|

| F. | Defective switch. | F. | Replace control. |

|

|

|

|

|

|

12. | Control does not regenerate | A. | If water flow display is not operative, refer to | A. | Refer to item 5 in this table. |

| automatically but does |

| item 5 in this table. |

|

|

| regenerate when REGEN | B. | Incorrect hardness and capacity settings. | B. | Set new control values. Refer to the Programming |

| button is depressed. |

|

|

| section. |

|

| C. | Defective circuit board. | C. | Replace control. |

|

|

|

|

| |

13. Run out of soft water between | A. | Improper regeneration. | A. | Repeat regeneration making certain that correct | |

| regenerations. |

|

|

| salt dosage is used. |

|

| B. | Fouled resin bed. | B. | Use resin cleaner. |

|

| C. | Incorrect salt setting. | C. | Set salt control to proper level. Refer to the |

|

|

|

|

| Programming section in this manual. |

|

| D. | Incorrect hardness or capacity settings. | D. | Set to correct values. Refer to the Programming |

|

|

|

|

| section in this manual. |

|

| E. | Water hardness has increased. | E. | Set to new value. Refer to the Programming |

|

|

|

|

| section in this manual. |

|

| F. | Restricted meter turbine rotation due to | F. | Remove meter housing, free up turbine, and flush |

|

|

| foreign material in meter housing ! |

| with clean water. Turbine should spin freely, if not, |

|

|

|

|

| replace meter. |

|

| G. | Excessive water usage below 1/5 gallon per | G. | Repair leaky plumbing and/or fixtures. |

|

|

| minute. |

|

|

|

|

|

|

|

|

30