004701-0 specifications

Generac Power Systems has established itself as a leading provider of backup power solutions, and one of its standout products is the Generac 004701-0. Renowned for its reliability and advanced features, this model is designed to meet the growing demand for dependable power in residential and commercial applications.At the heart of the Generac 004701-0 is its robust engine, which offers outstanding performance and efficiency. The unit is powered by a Generac 999cc V-Twin engine, specifically crafted to deliver reliable power during outages. This powerful engine ensures a significant output of up to 22,000 watts, making it suitable for larger homes or businesses that require more energy-intensive appliances to remain operational during outages.

One of the most notable features of the 004701-0 is its innovative True Power Technology. This technology provides clean and stable power, which is essential for sensitive electronics. Unlike some generators that produce a fluctuating output, Generac's True Power Technology ensures that the voltage remains consistent, preventing damage to your appliances.

Another key characteristic of the Generac 004701-0 is its user-friendly controls. The unit comes equipped with a comprehensive LED display that provides vital information at a glance, such as runtime hours and maintenance intervals. This feature ensures users can monitor their unit effectively and keep it in optimal condition.

The generator also boasts an advanced communication system that allows for remote monitoring. With the Generac Mobile Link app, users can check real-time status updates, monitor power usage, and receive alerts directly on their smartphone or tablet. This level of connectivity adds convenience and peace of mind, as users can stay informed about their power systems from anywhere.

Built with durability in mind, the 004701-0 features a corrosion-resistant enclosure that can withstand various environmental conditions. Its weather-resistant design makes it suitable for outdoor installation, ensuring that it remains operational when most needed.

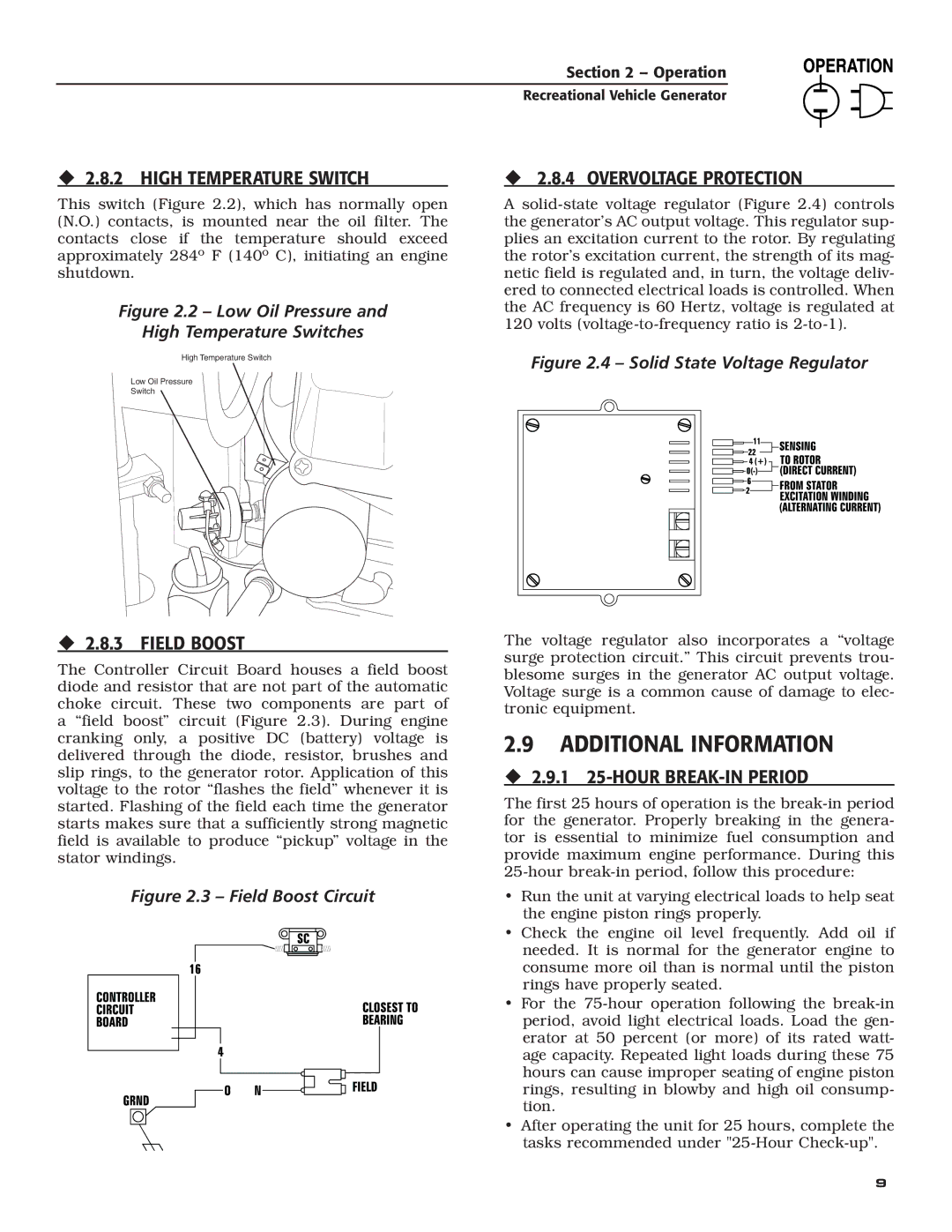

The Generac 004701-0 is also designed with user safety in mind. It incorporates several safety features, including a low-oil shutdown and high-temperature shutdown, which help protect the engine from potential risks. This commitment to safety, combined with its powerful performance and advanced technology, makes the 004701-0 an exceptional choice for anyone looking for a dependable backup power solution.

Whether you're facing a storm, a power grid failure, or simply need reliable power for everyday use, the Generac 004701-0 stands ready to deliver, ensuring that you and your loved ones stay safe and comfortable.