SERVICING

S-16C CHECKING ECM MOTOR WINDINGS

HIGH VOLTAGE!

Disconnect ALL power before servicing or installing. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death.

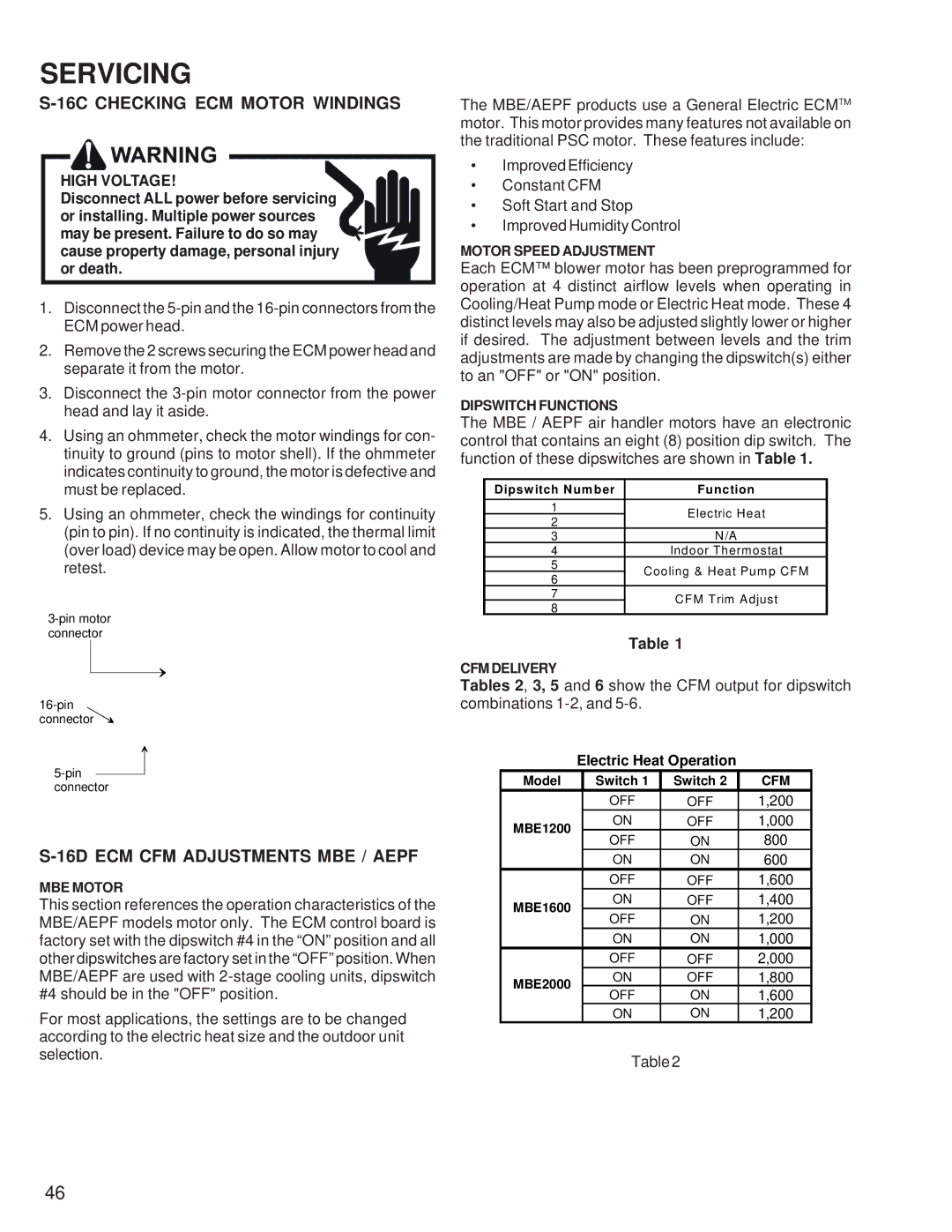

1.Disconnect the

2.Remove the 2 screws securing the ECM power head and separate it from the motor.

3.Disconnect the

4.Using an ohmmeter, check the motor windings for con- tinuity to ground (pins to motor shell). If the ohmmeter indicates continuity to ground, the motor is defective and must be replaced.

5.Using an ohmmeter, check the windings for continuity (pin to pin). If no continuity is indicated, the thermal limit (over load) device may be open. Allow motor to cool and retest.

![]() connector

connector

S-16D ECM CFM ADJUSTMENTS MBE / AEPF

MBE MOTOR

This section references the operation characteristics of the MBE/AEPF models motor only. The ECM control board is factory set with the dipswitch #4 in the “ON” position and all other dipswitches are factory set in the “OFF” position. When MBE/AEPF are used with

For most applications, the settings are to be changed according to the electric heat size and the outdoor unit selection.

The MBE/AEPF products use a General Electric ECMTM motor. This motor provides many features not available on the traditional PSC motor. These features include:

•Improved Efficiency

•Constant CFM

•Soft Start and Stop

•Improved Humidity Control

MOTOR SPEED ADJUSTMENT

Each ECM™ blower motor has been preprogrammed for operation at 4 distinct airflow levels when operating in Cooling/Heat Pump mode or Electric Heat mode. These 4 distinct levels may also be adjusted slightly lower or higher if desired. The adjustment between levels and the trim adjustments are made by changing the dipswitch(s) either to an "OFF" or "ON" position.

DIPSWITCH FUNCTIONS

The MBE / AEPF air handler motors have an electronic control that contains an eight (8) position dip switch. The function of these dipswitches are shown in Table 1.

Dipswitch Number | Function | |

1 | Electric Heat | |

2 | ||

| ||

3 | N/A | |

4 | Indoor Thermostat | |

5 | Cooling & Heat Pump CFM | |

6 | ||

| ||

7 | CFM Trim Adjust | |

8 | ||

|

Table 1

CFM DELIVERY

Tables 2, 3, 5 and 6 show the CFM output for dipswitch combinations

Electric Heat Operation

Model | Switch 1 | Switch 2 | CFM | |

| OFF | OFF | 1,200 | |

MBE1200 | ON | OFF | 1,000 | |

OFF | ON | 800 | ||

| ||||

| ON | ON | 600 | |

| OFF | OFF | 1,600 | |

MBE1600 | ON | OFF | 1,400 | |

OFF | ON | 1,200 | ||

| ||||

| ON | ON | 1,000 | |

| OFF | OFF | 2,000 | |

MBE2000 | ON | OFF | 1,800 | |

OFF | ON | 1,600 | ||

| ||||

| ON | ON | 1,200 |

Table 2

46