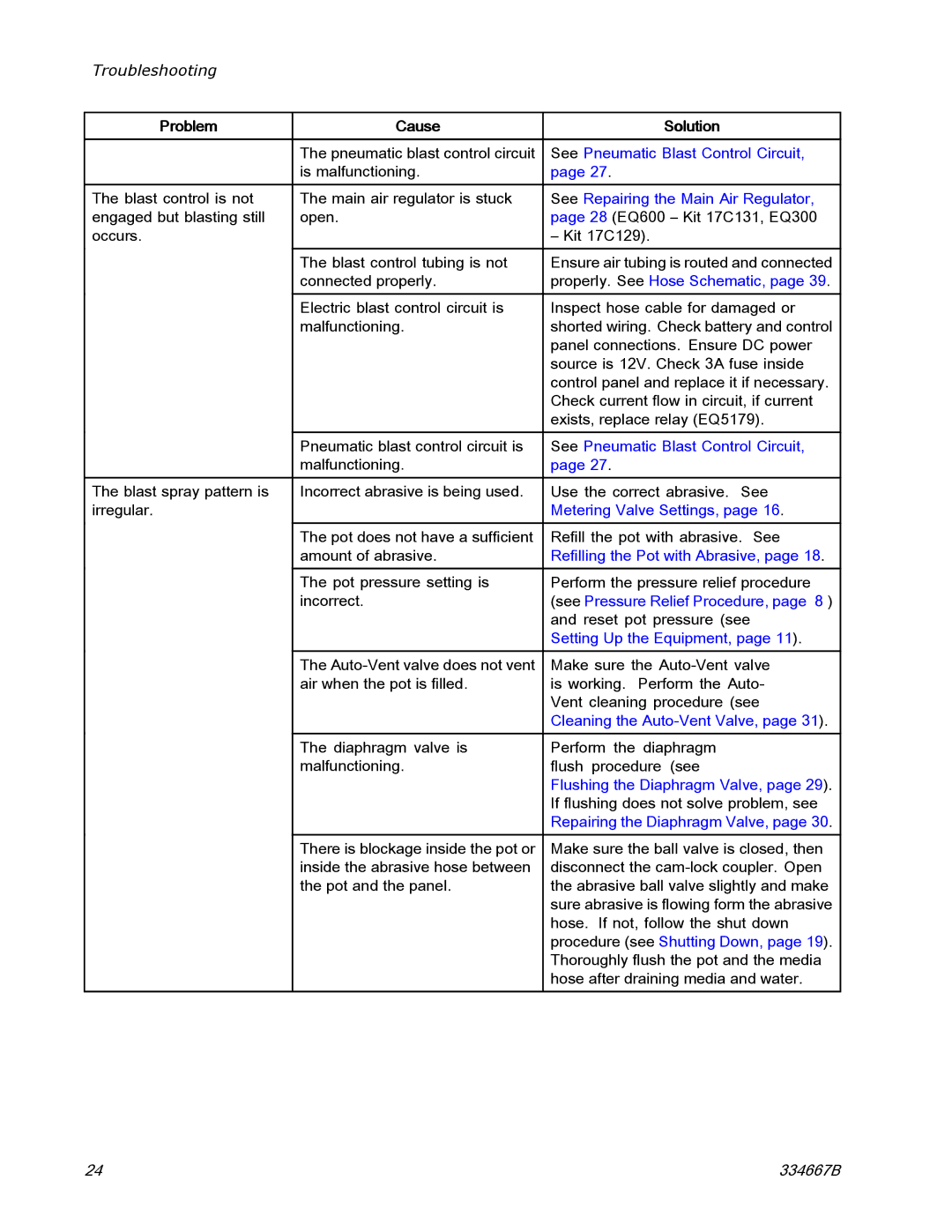

Troubleshooting

Problem | Cause | Solution |

|

|

|

| The pneumatic blast control circuit | See Pneumatic Blast Control Circuit, |

| is malfunctioning. | page 27. |

The blast control is not | The main air regulator is stuck | See Repairing the Main Air Regulator, |

engaged but blasting still | open. | page 28 (EQ600 – Kit 17C131, EQ300 |

occurs. |

| – Kit 17C129). |

| The blast control tubing is not | Ensure air tubing is routed and connected |

| connected properly. | properly. See Hose Schematic, page 39. |

| Electric blast control circuit is | Inspect hose cable for damaged or |

| malfunctioning. | shorted wiring. Check battery and control |

|

| panel connections. Ensure DC power |

|

| source is 12V. Check 3A fuse inside |

|

| control panel and replace it if necessary. |

|

| Check current flow in circuit, if current |

|

| exists, replace relay (EQ5179). |

| Pneumatic blast control circuit is | See Pneumatic Blast Control Circuit, |

| malfunctioning. | page 27. |

The blast spray pattern is | Incorrect abrasive is being used. | Use the correct abrasive. See |

irregular. |

| Metering Valve Settings, page 16. |

| The pot does not have a sufficient | Refill the pot with abrasive. See |

| amount of abrasive. | Refilling the Pot with Abrasive, page 18. |

| The pot pressure setting is | Perform the pressure relief procedure |

| incorrect. | (see Pressure Relief Procedure, page 8 ) |

|

| and reset pot pressure (see |

|

| Setting Up the Equipment, page 11). |

| The | Make sure the |

| air when the pot is filled. | is working. Perform the Auto- |

|

| Vent cleaning procedure (see |

|

| Cleaning the |

| The diaphragm valve is | Perform the diaphragm |

| malfunctioning. | flush procedure (see |

|

| Flushing the Diaphragm Valve, page 29). |

|

| If flushing does not solve problem, see |

|

| Repairing the Diaphragm Valve, page 30. |

| There is blockage inside the pot or | Make sure the ball valve is closed, then |

| inside the abrasive hose between | disconnect the |

| the pot and the panel. | the abrasive ball valve slightly and make |

|

| sure abrasive is flowing form the abrasive |

|

| hose. If not, follow the shut down |

|

| procedure (see Shutting Down, page 19). |

|

| Thoroughly flush the pot and the media |

|

| hose after draining media and water. |

24 | 334667B |