Contents

Important Safety Instructions

EcoQuip Vapor Abrasive Blast System

Models

Related Manuals

Dust and Debris Hazard

Burn Hazard

Metric

OEM System Guidelines

Compressor Size and Hose Length Minimum ID Metric

System Component Identification

EQ300C and EQ600C

Key

DataTrak Controls

DataTrak see DataTrak Controls,

Pressure Relief Procedure

Checklist Before Starting

Operation

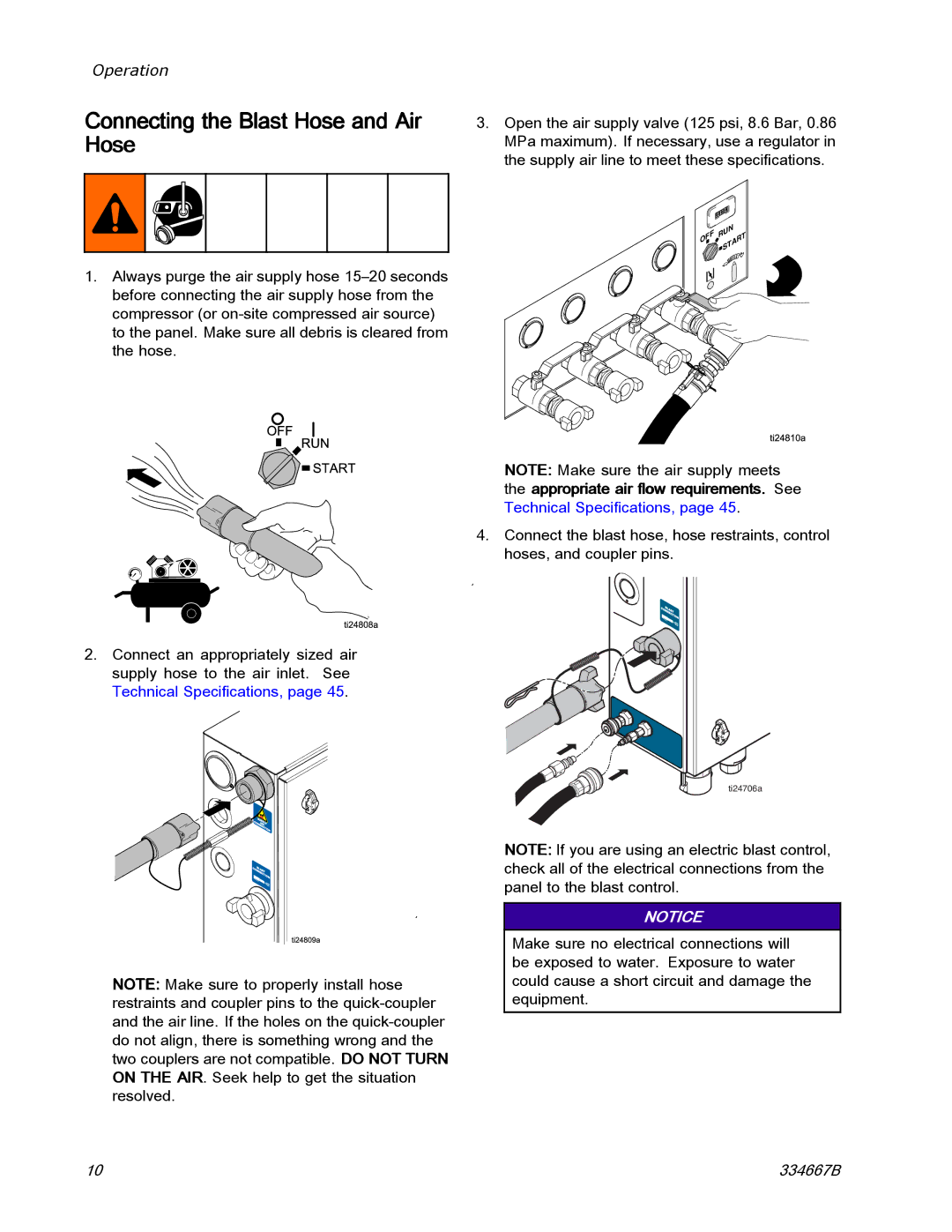

Connecting the Blast Hose and Air Hose

Setting Up the Equipment

10 gal 200-500 lb

Ti24824a

0 0 0 8 8 0 0 0 3

Blasting Tips

Blasting on Higher Surfaces

Wood

Metering Valve Settings

Grit Size Blast Pressure Abrasive Dose Blast Angle General

Steel

Using the Wash Feature

Refilling the Pot with Abrasive

Shutting Down

Operation

Winterizing the Equipment

See Cleaning the Auto-Vent Valve,

Troubleshooting

Problem Cause Solution

See Repairing the Main Air Regulator

Procedure see Shutting Down,

See Setting Up the Equipment,

See Repairing the Diaphragm Valve

Intact. See Hose Schematic,

See Pressure Relief Procedure,

Properly. See Hose Schematic,

Metering Valve Settings,

Setting Up the Equipment,

If flushing does not solve the problem, see

Troubleshooting Examples

Checking for Leaks

Pneumatic Blast Control Circuit

Perform Pressure Relief Procedure,

Repairing the Main Air Regulator

Repair

Flushing the Diaphragm Valve

Repairing the Diaphragm Valve

Perform the Pressure Relief Procedure,

Cleaning the Auto-Vent Valve

Replace Battery

Replacing the DataTrak Battery

Approved Batteries

Replace Fuse

Replacing the DataTrak Fuse

Approved Fuses DataTrak Part Series Letter Fuse Required

Parts

EQ300C and EQ600C

EQ300C and EQ600C Parts List

Pressure POT

Enclosure

Enclosure Parts List

Part Description Qty

Pressure Pot

Pressure Pot Parts List

Ref. Part Description Qty

Hose Schematic

EcoQuip Trailer Systems

Vapor Abrasive Blast Systems and Accessories

EcoQuip Skid Systems

Model Series Brakes

Model

Mobile/Skid Units

Trailer Units

Model Description

Nozzles

Hoses

Model Description Type Length Blast Control

Other Accessories

Common Spare Parts

Dimensions

EQ300S

Technical Specifications

EQ600S

Graco Extended Warranty for EcoQuip Components

Graco Information