Flushing the Diaphragm Valve

This procedure can be performed with the component still mounted in the panel.

If

1.Operate the unit in WASH (see

Using the Wash Feature, page 17) until all abrasive clears from the blast hose.

2.Close the abrasive ball valve, then turn the selector valve to RINSE.

Repair

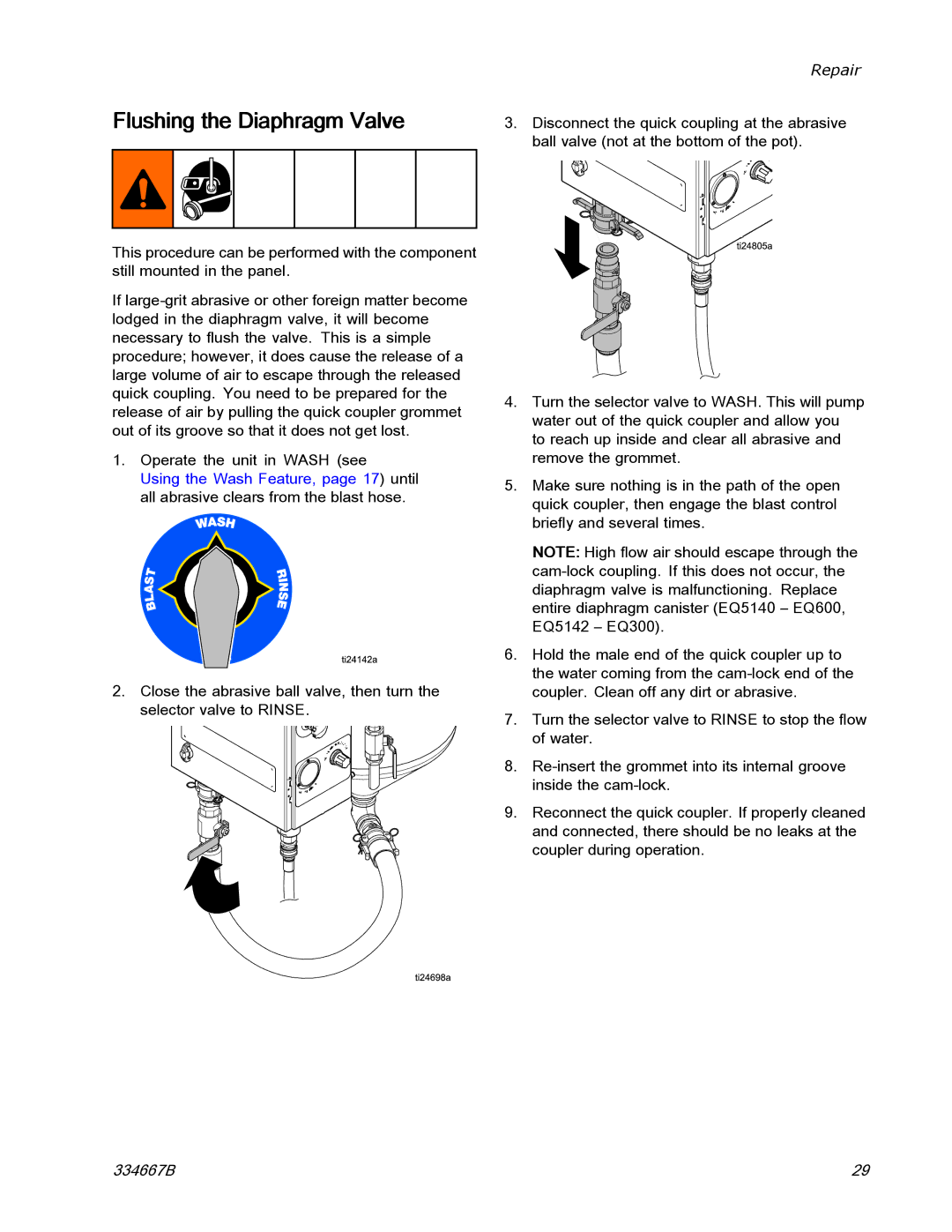

3.Disconnect the quick coupling at the abrasive ball valve (not at the bottom of the pot).

4.Turn the selector valve to WASH. This will pump water out of the quick coupler and allow you to reach up inside and clear all abrasive and remove the grommet.

5.Make sure nothing is in the path of the open quick coupler, then engage the blast control briefly and several times.

NOTE: High flow air should escape through the

6.Hold the male end of the quick coupler up to the water coming from the

7.Turn the selector valve to RINSE to stop the flow of water.

8.

9.Reconnect the quick coupler. If properly cleaned and connected, there should be no leaks at the coupler during operation.

334667B | 29 |